Thermal insulation structure and high-temperature furnace

A high-temperature furnace and insulation layer technology, applied in the direction of single crystal growth, polycrystalline material growth, crystal growth, etc., can solve the problems of unsatisfactory insulation effect, high thermal conductivity of alumina, and volatilization of carbon atoms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

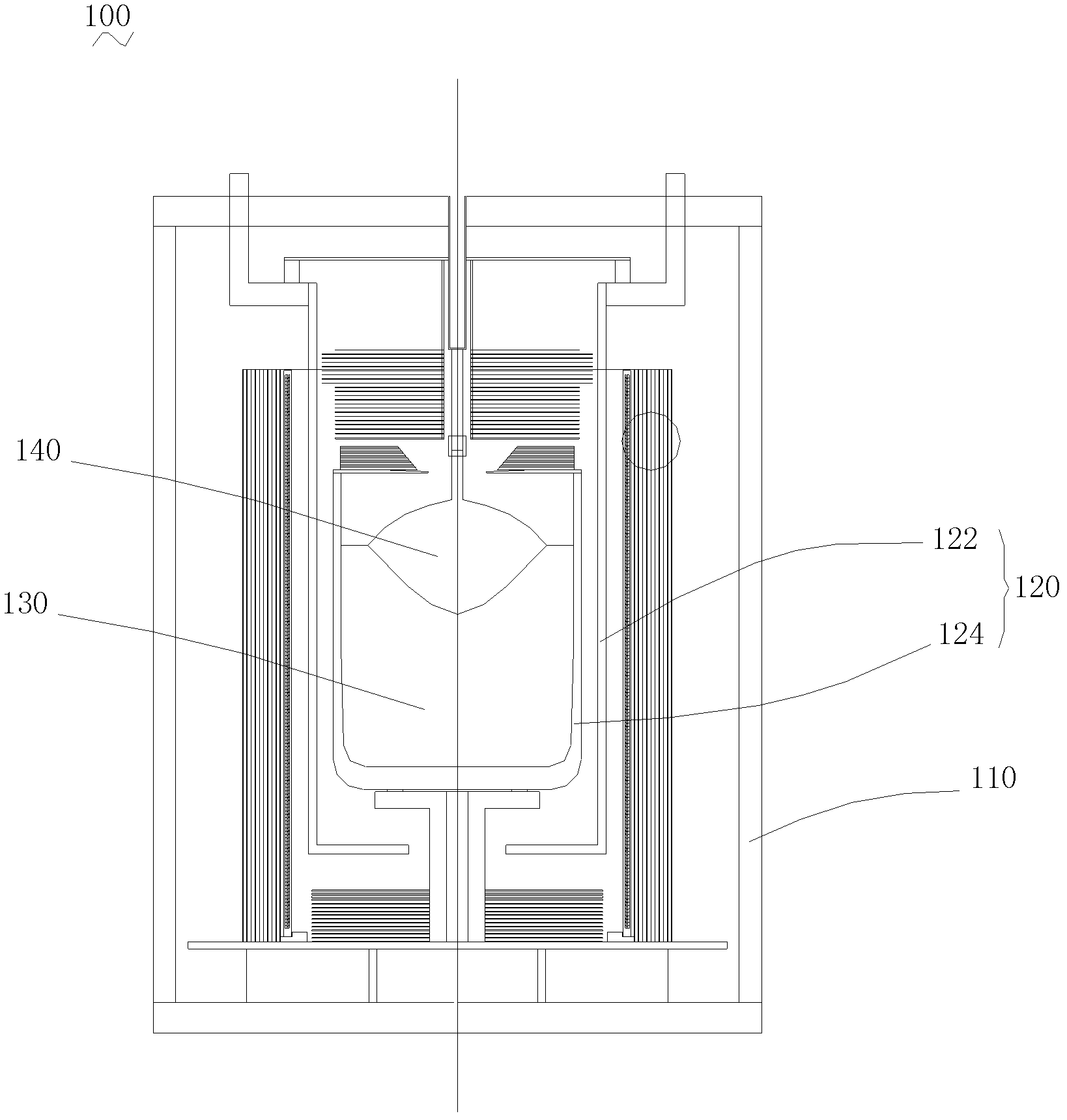

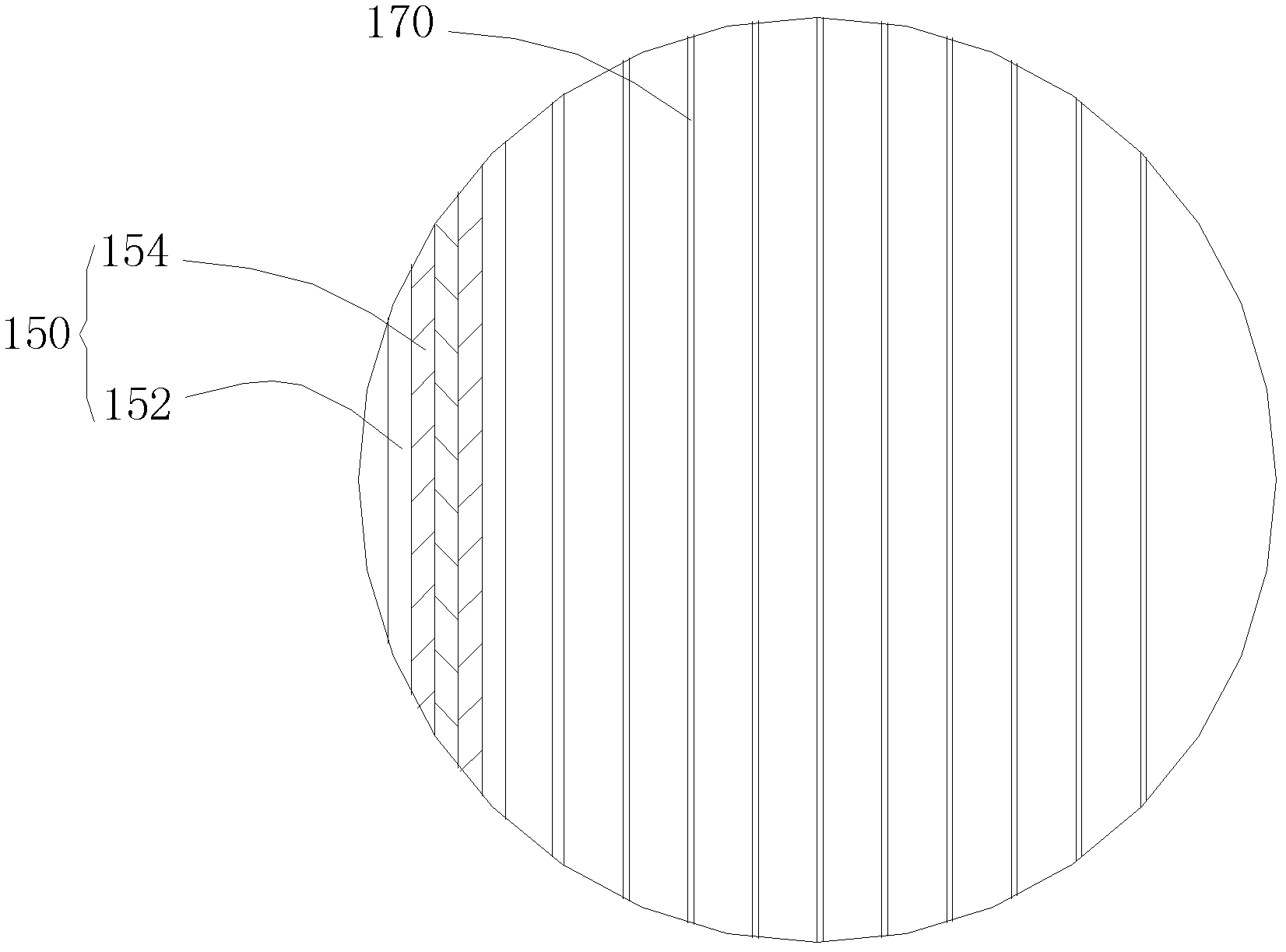

Embodiment 1

[0037] Inside the tungsten cylinder 152 with a thickness of 10mm, a certain manufacturing method is used to fill the interior with 3 layers of carbon felt material 154 with a thickness of 2mm, that is, the outer layer of the heat preservation structure is the tungsten cylinder 152, and the inner layer is 3 layers of carbon felt material with a thickness of 2mm. 154. Then install it inside the sapphire crystal growth furnace as its side insulation layer structure 150, and use the installed sapphire crystal growth furnace to grow sapphire crystal 140. Due to its good heat preservation effect reduces the power of the crystal in each stage, thus reducing the energy consumption of the sapphire furnace. At the same time, due to the reduction of the power of the sapphire furnace, the voltage is basically constant, thereby reducing the current value. According to the ampere force formula, the ampere force existing in the tungsten rod heater 122 is much reduced, so that the deformation...

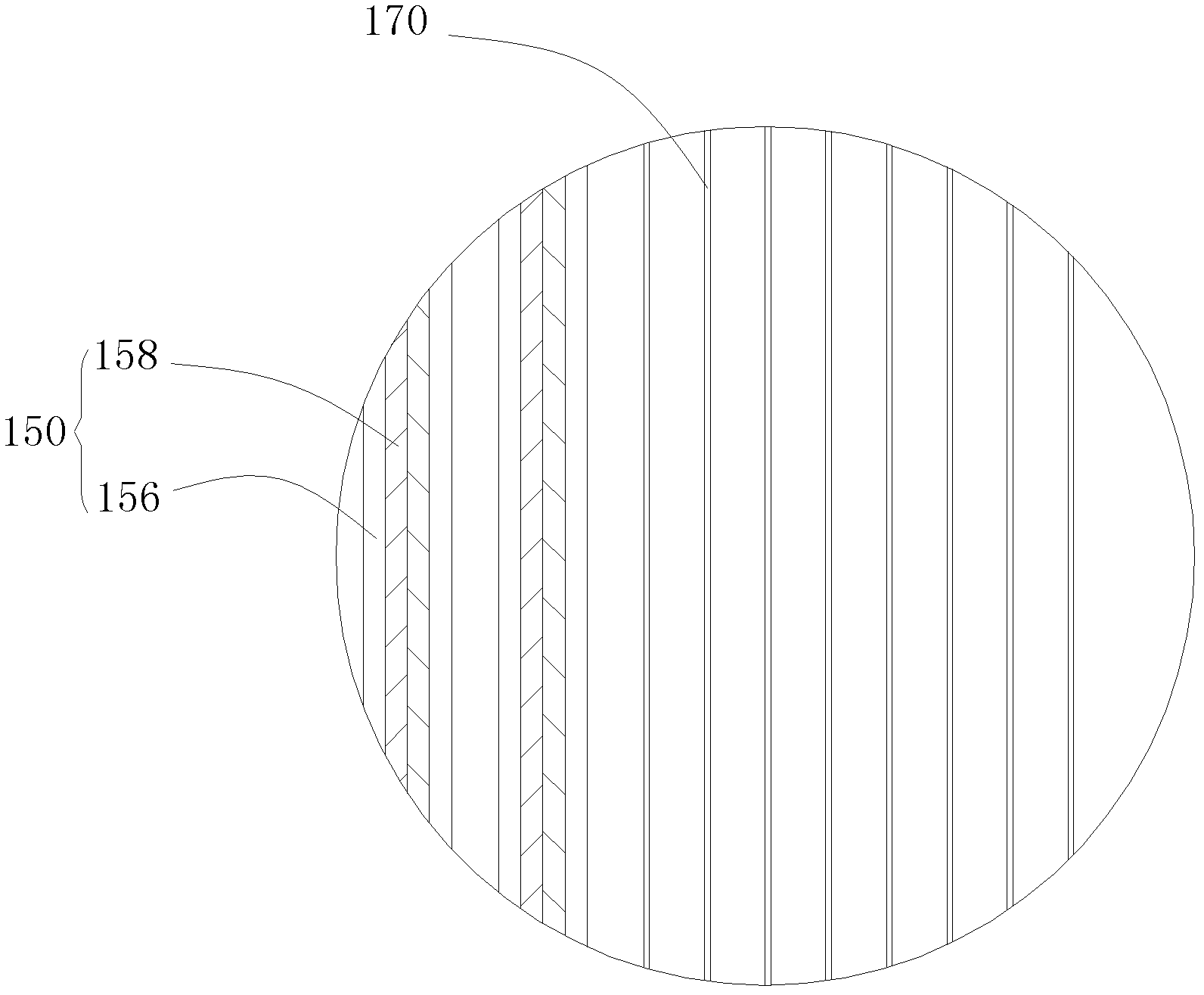

Embodiment 2

[0039] Inside the molybdenum cylinder 156 with a thickness of 10mm, a certain process is used to fill it with 2 layers of carbon felt material 158 with a thickness of 3mm, that is, the outer layer of the heat preservation structure is tungsten cylinder 156, and the inner layer is 2 layers of carbon felt material with a thickness of 3mm. 158. Then install it inside the sapphire crystal growth furnace as its side insulation layer structure 150, and grow the sapphire crystal 140 in the installed sapphire crystal growth furnace. Due to its good heat preservation effect reduces the power of the crystal in each stage, thus reducing the energy consumption of the sapphire furnace. At the same time, due to the reduction of the power of the sapphire furnace, the voltage is basically constant, thereby reducing the current value. Similarly, according to the ampere force formula, the ampere force existing in the tungsten rod heater 122 is greatly reduced, so that the deformation of the tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com