Data collecting device for micro tester

A technology of data acquisition and tester, which is applied in the direction of instruments, etc., can solve problems such as difficulty in mass production, long calibration time, and low efficiency, and achieve high production efficiency, simple operation, and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

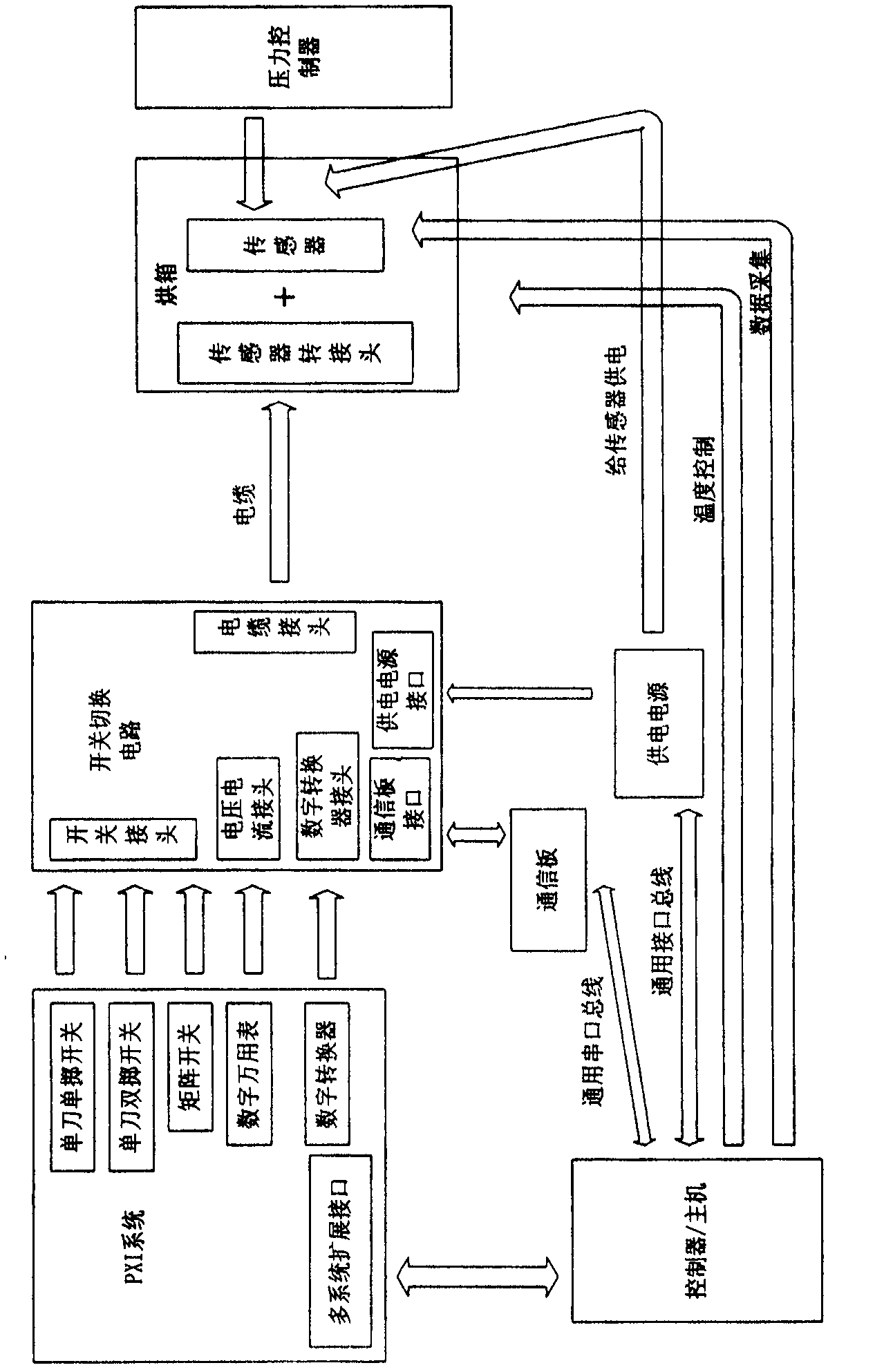

[0010] Such as figure 1 Shown, the micro-tester data acquisition device of the present invention comprises PXI system, switch switching circuit, baking oven, pressure controller, controller / host, communication board and power supply, and described PXI system is made of single pole single throw switch, single pole double throw Composed of switches, matrix switches, digital multimeters, digital converters and multi-system expansion interfaces, the switch switching circuit is composed of switch connectors, voltage and current connectors, digital converter connectors, communication board connectors, power supply connectors and cable connectors; there are sensors in the oven adapters and sensors. The single-pole single-throw switch, single-pole double-throw switch, and matrix switch in the PXI system are connected to the switch connector of the switch switching circuit through cables, the digital multimeter is connected to the voltage and current connector of the switch switching c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com