Liquid milk and preparation method thereof

A technology of liquid milk and milk, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of incapable of industrial scale production and poor effect, and achieve the effect of reducing complete dependence, delicate milk foam, and rich milk aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

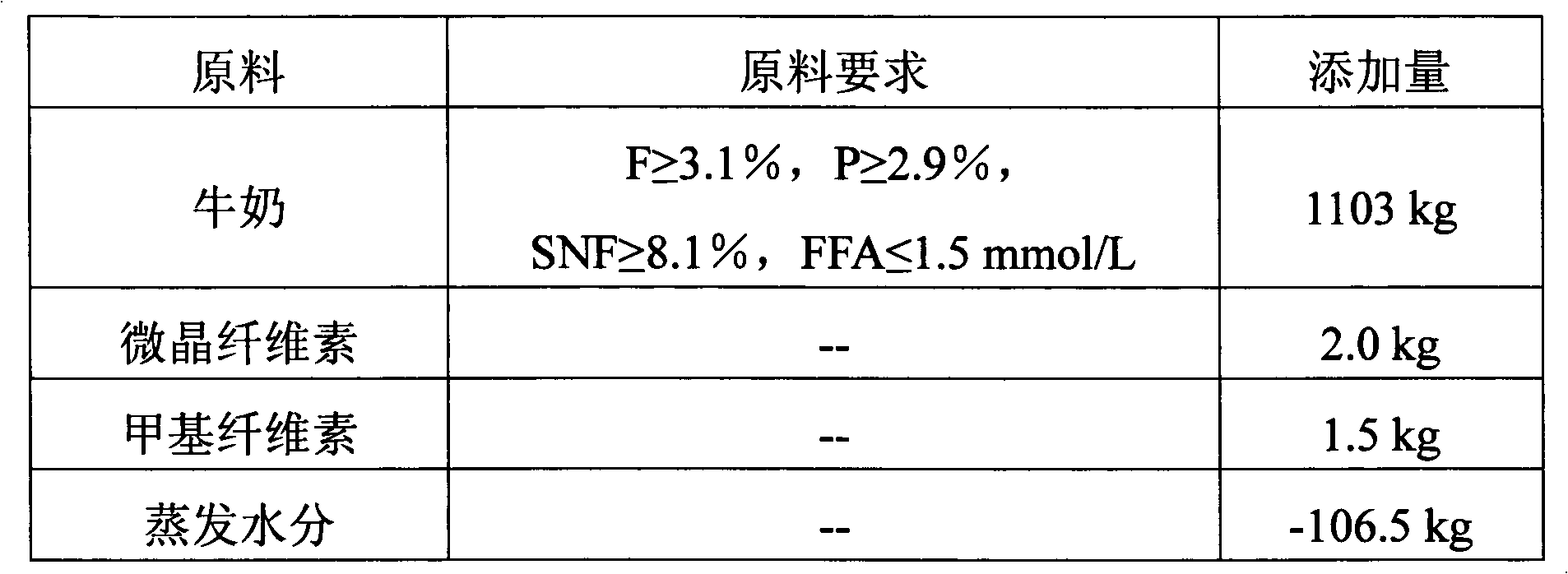

[0029] Product formula (calculated per ton of final product):

[0030]

[0031] The preparation method comprises the following steps:

[0032] (1) Concentrate the milk on double-effect low-temperature falling film concentration equipment, the concentration temperature is 40°C, and the concentration vacuum is -0.08MPa to obtain concentrated milk;

[0033] (2) According to the recipe, the condensed milk was dispersed into part of the milk at 40°C by using a water-powder mixer, and then the remaining milk was mixed for 20 minutes until uniform; the protein content was 3.2%. milk;

[0034] (3) The above solutions were mixed and homogenized, and sterilized: the homogenization temperature was 65°C, and a first-level homogenization was performed at 200 bar; the sterilization temperature was 120°C, and the time was 15 seconds;

[0035] (4) Cool the liquid obtained after the above sterilization to 0°C, let it stand still, and fill it.

[0036] The test results are as follows:

...

Embodiment 2

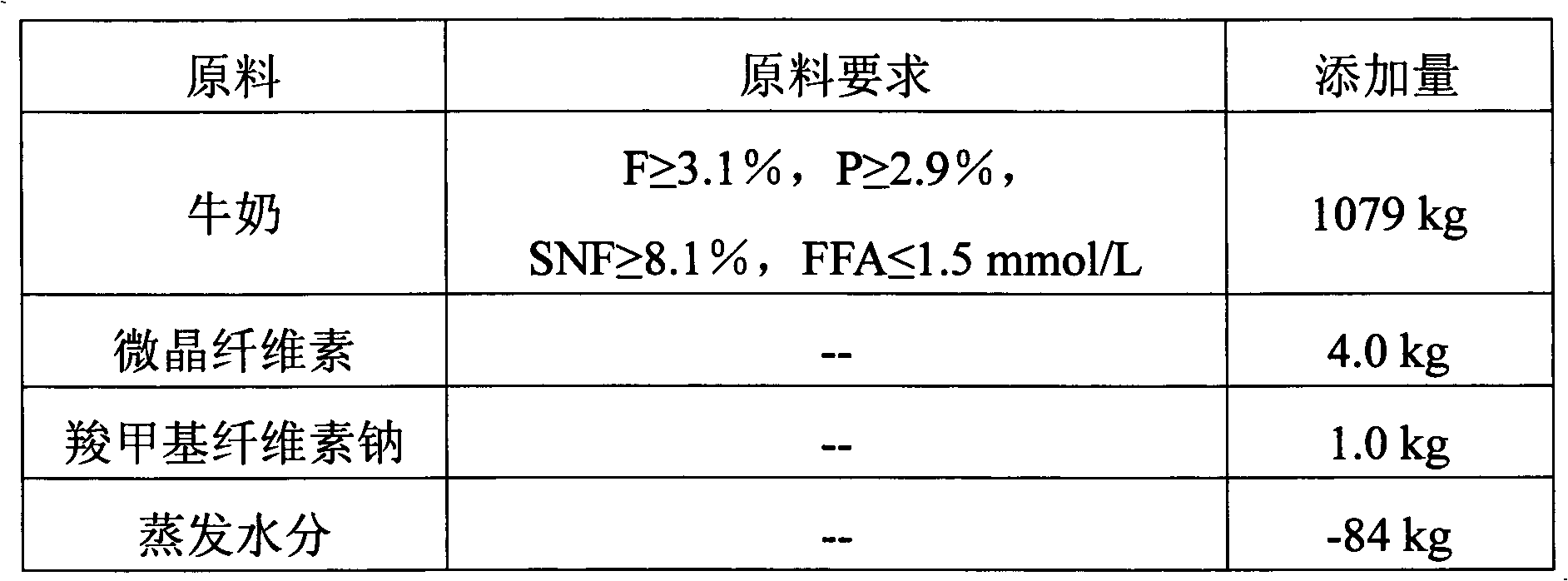

[0039] Product formula (calculated per ton of final product):

[0040]

[0041] The preparation method comprises the following steps:

[0042] (1) The milk is centrifugally degreased by a high-speed centrifuge, and then concentrated on a double-effect low-temperature falling film concentration equipment, the concentration temperature is 40°C, and the concentration vacuum is -0.06MPa to obtain concentrated milk;

[0043] (2) According to the recipe, disperse microcrystalline cellulose and sodium carboxymethyl cellulose into part of the milk at 50°C with a water-powder mixer, and then mix the remaining centrifuged skim milk for 20 minutes until uniform; obtain the protein content 3.2% milk;

[0044] (3) Mix and homogenize the above solutions and sterilize: the homogenization temperature is 70°C, and perform secondary homogenization at 30bar and 100bar; the sterilization temperature is 140°C, and the time is 15 seconds;

[0045] (4) Cool the liquid obtained after the above s...

Embodiment 3

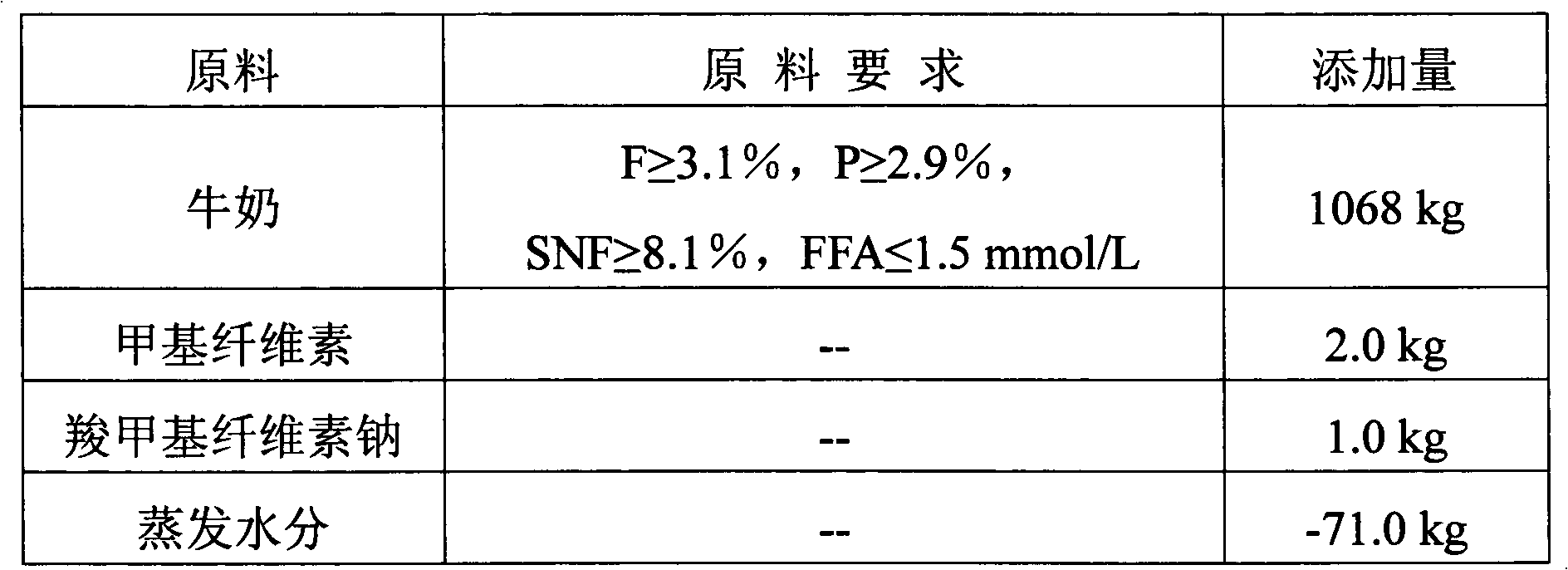

[0049] Product formula (calculated per ton of final product):

[0050]

[0051] The preparation method comprises the following steps:

[0052] (1) Concentrate the milk on double-effect low-temperature falling film concentration equipment, the concentration temperature is 50°C, and the concentration vacuum is -0.09MPa to obtain concentrated milk;

[0053] (2) Disperse the condensed milk according to the recipe, using a water-powder mixer to disperse methylcellulose and sodium carboxymethylcellulose into part of the milk at 45°C, and then mix the remaining milk for 20 minutes until uniform; the protein content is 3.1 % milk;

[0054] (3) Mix and homogenize the above solutions, and sterilize: the homogenization temperature is 65°C, and the first-level homogenization is carried out at 300bar; the sterilization temperature is 85°C, and the time is 15 seconds;

[0055] (4) Cool the liquid obtained after the above sterilization to 3°C, let it stand still, and fill it.

[0056] te...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap