Rocker type upper limb rehabilitation device and method for performing rehabilitation training by aid of rocker type upper limb rehabilitation device

A rehabilitation device and rocker-type technology, applied in the direction of passive exercise equipment, sports accessories, gymnastics equipment, etc., can solve the problems of inability to realize three-dimensional space movement, lack of flexibility, and patient discomfort, and achieve diversified training modes , Simple and compact structure, wide crowd effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

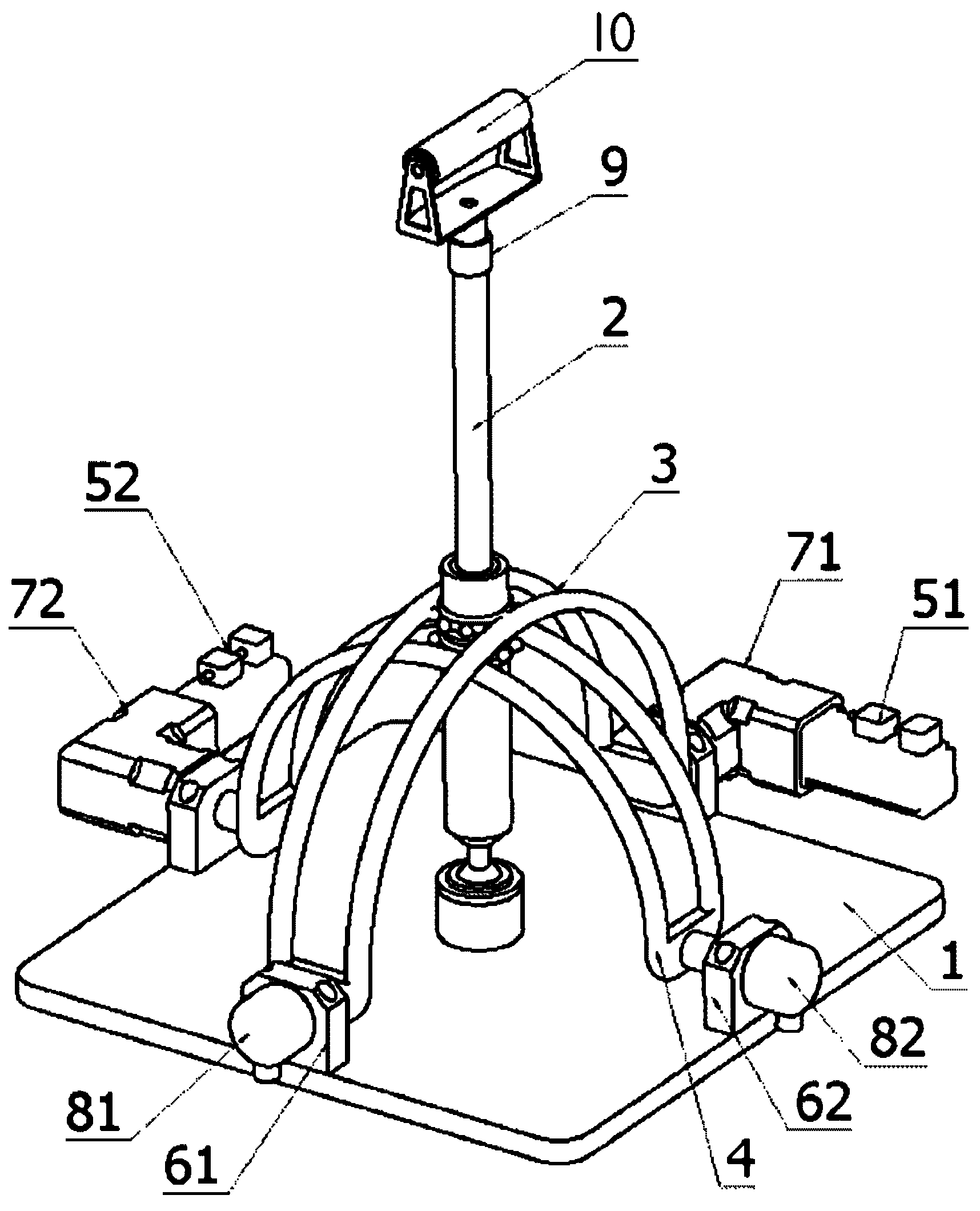

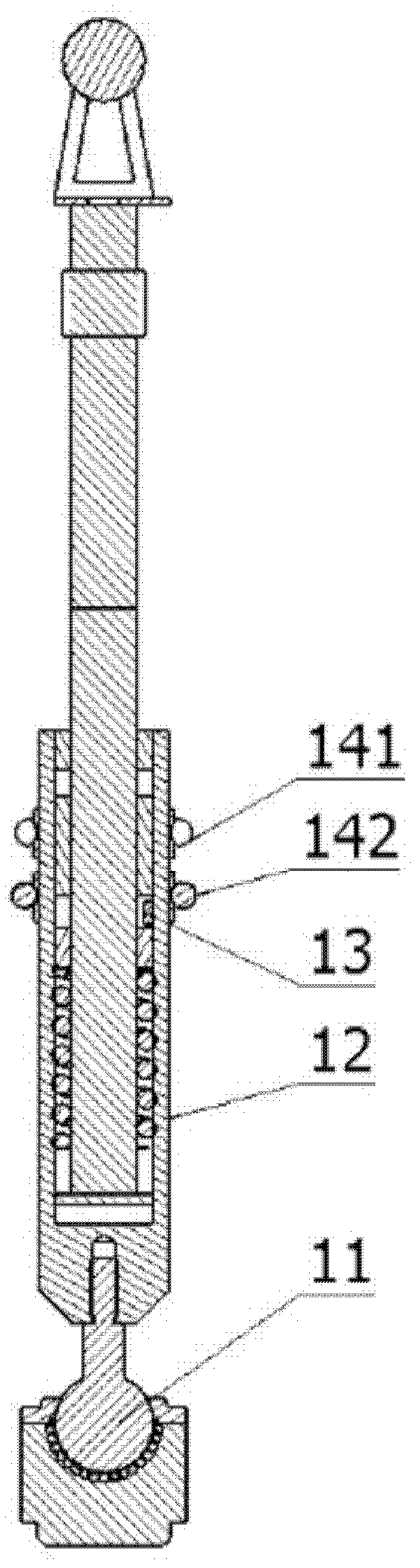

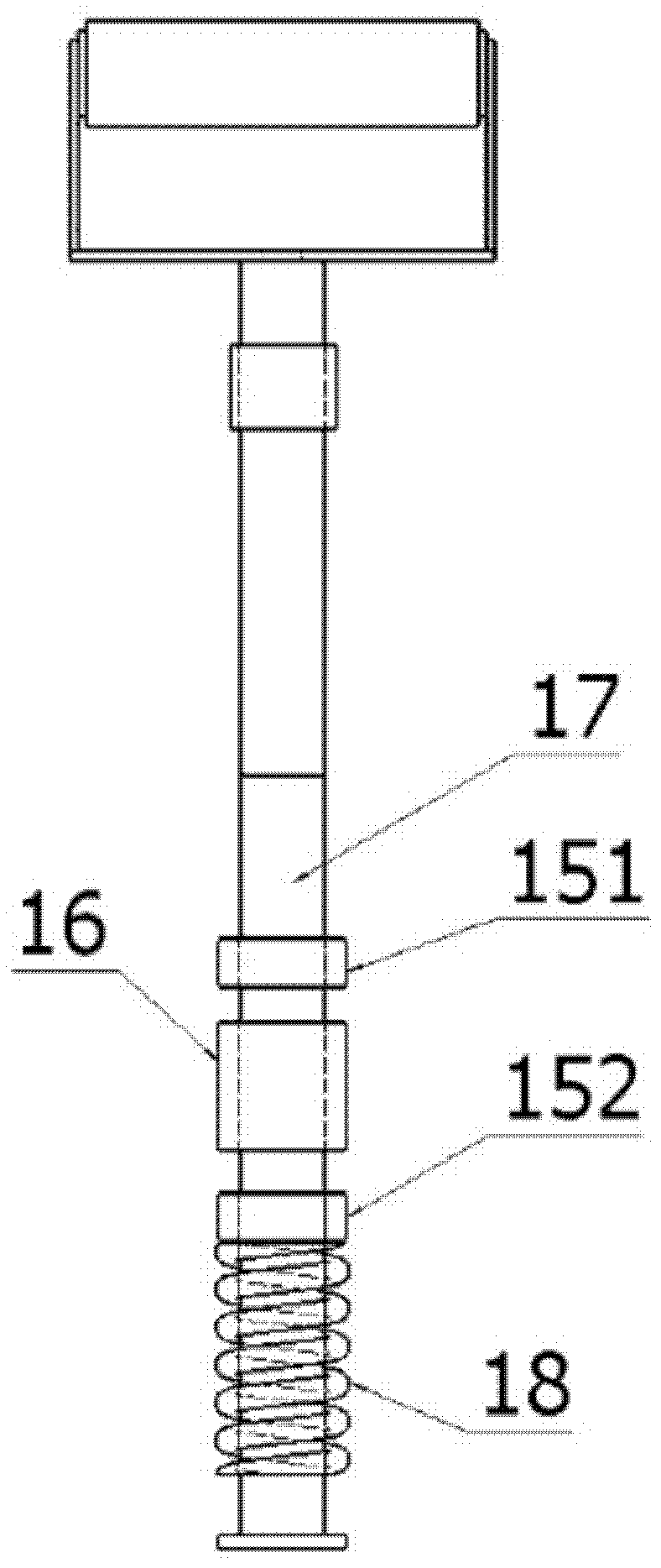

[0048] Figure 1 to Figure 4The labels in are: base 1, telescopic rocker 2, outer arc track 3, inner arc track 4, first servo motor 51, second servo motor 52, bearing housings (61, 62), first reducer 71 , second reducer 72, first photoelectric encoder 81, second photoelectric encoder 82, six-axis force sensor 9, handle 10, universal ball 11, rocker shell 12, position sensor 13, sliding bearing (141,142 ), positioning bearing (151, 152), mover 16, stator 17, spring 18, computer 19, first servo motor driver 21, second servo motor driver 22, linear motor driver 23, signal conditioner 24, motion control card 25. Display 26.

[0049] Such as figure 1 As shown, the rocker type upper limb rehabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com