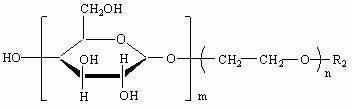

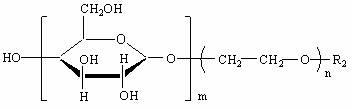

Multifunctional foam liquid soap containing glucoside and derivatives of glucoside, and preparation method thereof

A multifunctional, derivative technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of improper use of surfactants, easy residue on the skin, dry skin, etc., to prevent Dry and chapped skin, soft touch, anti-bacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Raw material weight percent composition is:

[0032] C 12~14 Fatty alcohol ether citrate (EO=3) 6.0%

[0033] C 12~14 Alkyl glucoside (polymerization degree DP=1.8) 2.5%

[0034] CMEA 2.0%

[0035] Polyhexamethylene biguanide 0.1%

[0036] Fragrance 0.2%

[0037] Pigment 0.0004%

[0038] Deionized water balance

[0039] Preparation:

[0040] Raw material is by its weight percentage, and C 12~14 Add 70% of the total weight of fatty alcohol ether citrate (EO=3) and deionized water into the chemical tank, add NaOH under stirring to neutralize the pH to 6.2, and then add C at 73°C 12~14 Alkyl glucoside (polymerization degree DP=1.8) and CMEA, stir until all the raw materials are dissolved, then cool down to 30°C, then add polyhexamethylene biguanide, pigment, flavor and the rest of deionized water, and stir evenly to obtain the Multifunctional foaming hand sanitizer described above.

Embodiment 2

[0042] Raw material weight percent composition is:

[0043] C 8~10 Alkyl glycoside citrate (DP=1.2) 7.0%

[0044] C 16~18 Alkyl glucoside (DP=1.2) 2.0%

[0045] CMEA 1.2%

[0046] Polyhexamethylene biguanide 0.5%

[0047] Fragrance 0.3%

[0048] Pigment 0.0006%

[0049] Deionized water balance

[0050] Preparation:

[0051] Raw material is by its weight percentage, and C 8~10 Add 80% of the total weight of alkyl glycoside citrate (DP=1.2) and deionized water to the chemical tank, add NaOH under stirring to neutralize to pH 7.0, then add C at 70°C 16~18 Alkyl glucoside (DP=1.2) and CMEA, stir until the raw materials are completely dissolved, then cool down to 35°C, then add polyhexamethylene biguanide, pigment, essence and the rest of deionized water, and stir well to obtain the polyhexamethylene biguanide Functional foaming hand sanitizer.

Embodiment 3

[0053] Raw material weight percent composition is:

[0054] C 16~18 Alcohol ether glycoside citrate (EO=6, DP=1.8) 9.0%

[0055] C 12~14 Alcohol ether glycoside (EO=9, DP=1.8) 1.0%

[0056] CMEA 0.5%

[0057] Laurylguanidine 0.7%

[0058] Fragrance 0.1%

[0059] Pigment 0.001%

[0060] Deionized water balance

[0061] Preparation:

[0062] Raw material is by its weight percentage, and C 16~18 Add 73% of the total weight of alcohol ether glycoside citrate (EO=6, DP=1.8) and deionized water to the chemical tank, add NaOH under stirring to neutralize to pH 6.0, then add C at 80°C 12~14 Alcohol ether glycoside (EO=9, DP=1.8) and CMEA, stir until all the raw materials are dissolved, then cool down to 40°C, then add dodecylguanidine, pigment, essence and the rest of deionized water, and stir evenly to get The multifunctional foaming hand sanitizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com