Single edge groove submerged arc welding technique of plate with moderate thickness

A welding process and submerged arc welding technology, which is applied in the field of submerged arc welding of medium and heavy plates with single edge grooves, can solve the problems of easy slag inclusion, large welding residual stress in welded joints, and difficulty in molten pool, and save welding materials. , Reduce welding man-hours, solve the effect of welding methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Implementation example 1: S460 submerged arc welding welding test.

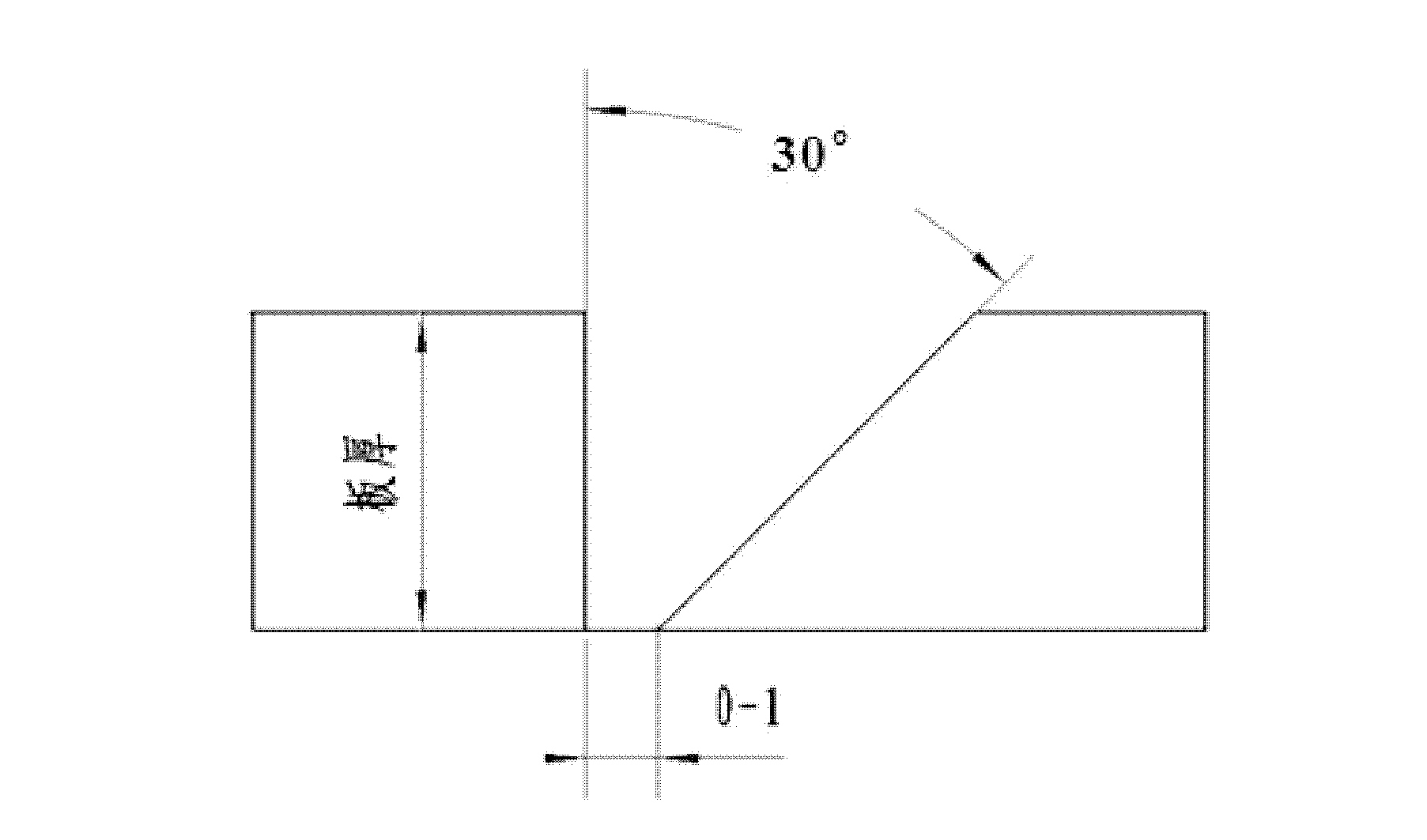

[0014] For the schematic diagram of welding test plate group, see figure 1 .

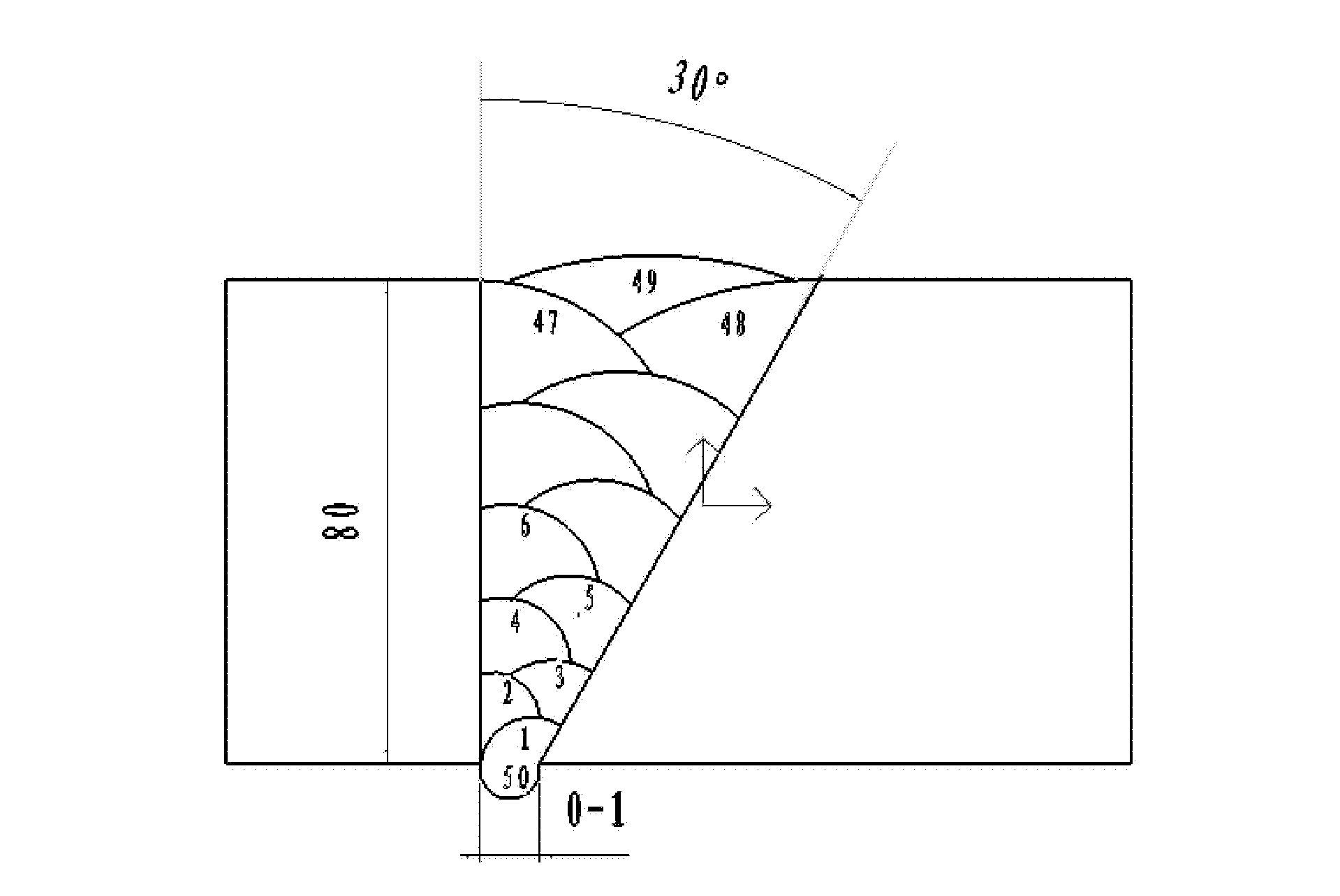

[0015] Welding process: DC reverse connection method is adopted; φ3.2 welding wire is used for the first to third layers on the front of the weld bead, the rod elongation is 3.0cm, the current is 400A, the voltage is 24V, and the welding speed is 57cm / min; the other layers on the front of the weld bead use φ4 welding wire. Rod elongation 3.5cm, current 600A, voltage 30V, welding speed 45cm / min; after the front bead is completed, the back bead is flanged and welded, the back bead layer is made of φ4 welding wire, the rod elongation is 4.2cm, current 700A, voltage 35V, The welding speed is 36cm / min, and the average heat input is 24kJ / cm. For a schematic diagram of the weld see figure 2 , welding process parameters are shown in Table 1.

[0016] Table 1 Welding process parameters of welding test plate

[0017]

Embodiment 2

[0018] Implementation example 2: S355 submerged arc welding welding test.

[0019] For the schematic diagram of welding test plate group, see figure 1 .

[0020] Welding process: DC reverse connection method is adopted; φ3.2 welding wire is used for the first to third layers of the front side of the weld bead, the rod elongation is 3.0cm, the current is 400A, the voltage is 24V, and the welding speed is 57cm / min; the front side of the weld bead 4~12 uses φ4 welding wire , rod elongation 3.5cm, current 600A, voltage 30V, welding speed 45cm / min; weld bead front 13~55 uses φ4 welding wire, rod elongation 3.5cm, current 680A, voltage 34V, welding speed 40cm / min; front weld bead After completion, the back bead is flanged and welded, the back bead layer is made of φ4 welding wire, the rod elongation is 4.2cm, the current is 700A, the voltage is 35V, the welding speed is 36cm / min, and the average heat input is 35kJ / cm.

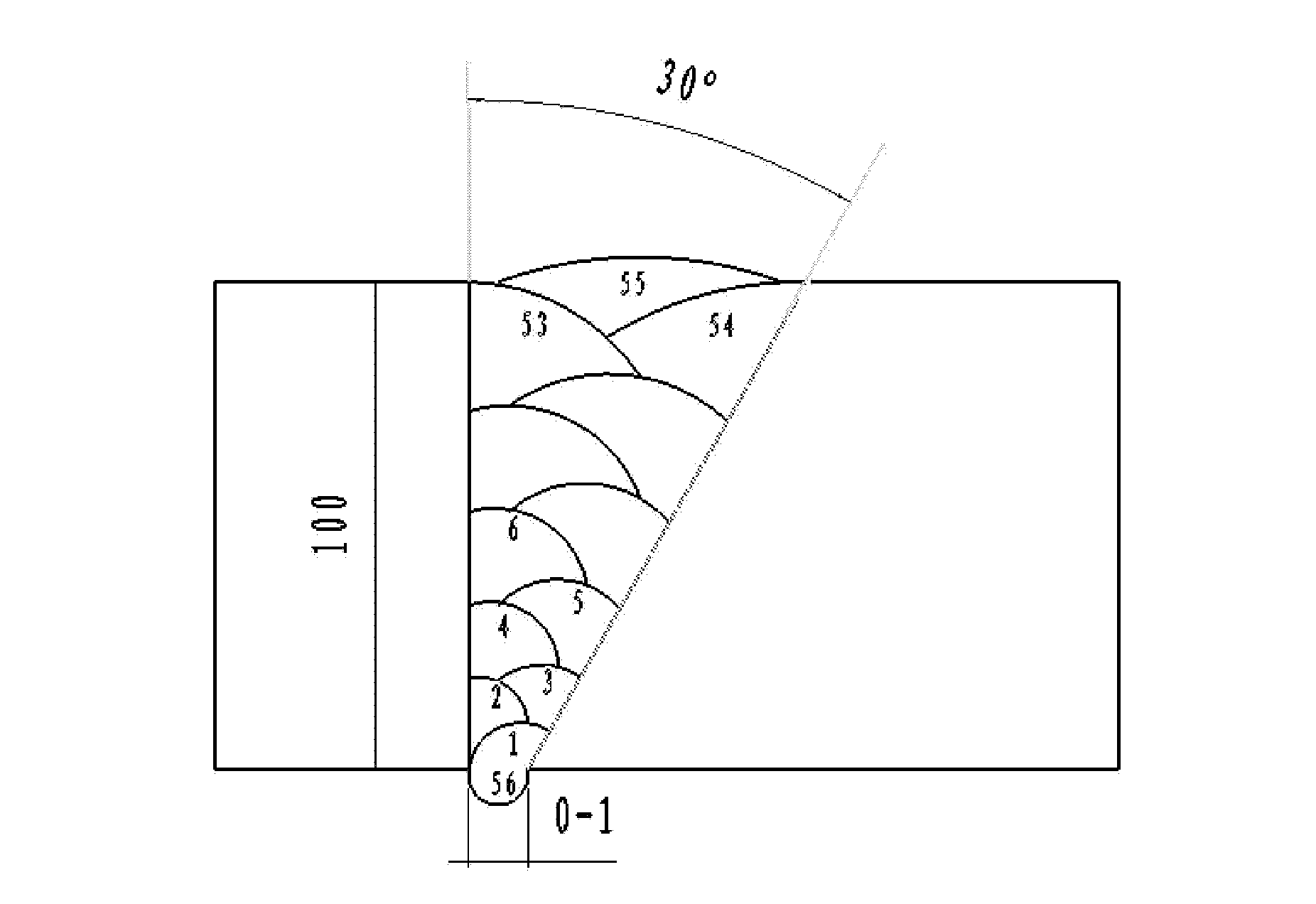

[0021] For a schematic diagram of the weld see image 3 , we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com