Drill tapping machine

A technology of tapping machine and control box, which is applied in metal processing machinery parts, metal processing, automatic control devices, etc. deliver fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

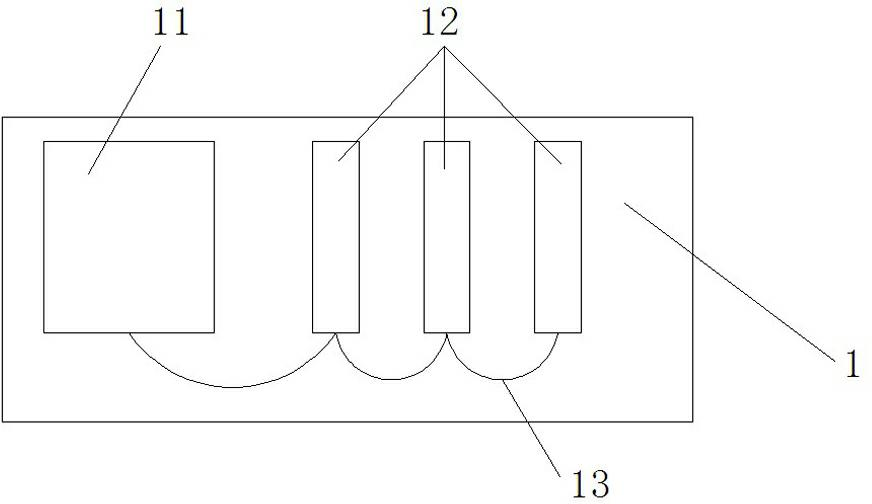

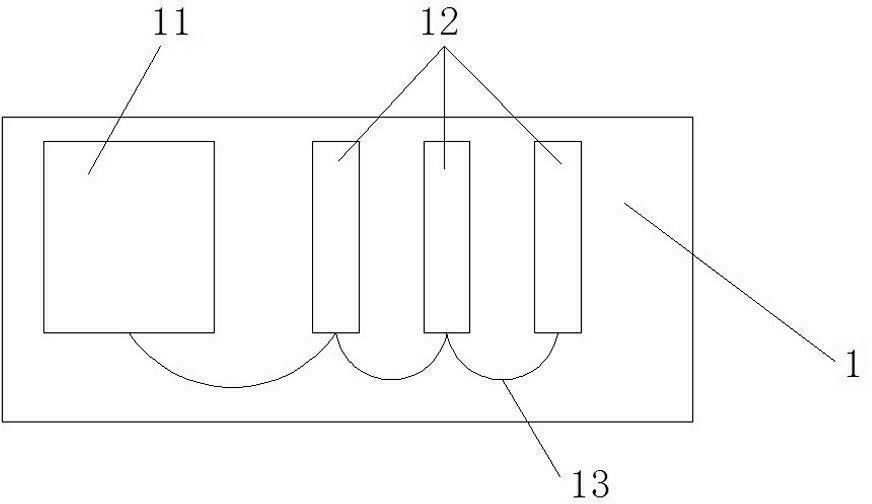

[0016] As shown in the figure, a drilling and tapping machine includes a control box 1 with sealed gaps. The control box 1 is equipped with a frequency converter 11 for controlling the spindle speed and controlling the travel of the spindle on the X, Y, and Z axes respectively. The drive 12, the signal transmission end between the frequency converter 11 and the drive 12 is connected through an optical fiber 13.

[0017] The outer surface of the optical fiber 13 is sequentially provided with a coating layer, a strengthening layer and an outer sheath from the inside to the outside. The strengthening layer is preferably a braided layer of stainless steel, and ointment is filled between the coated optical fibers. An anti-oil coating is also provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com