Resin composition

A resin composition and resin technology, applied in layered products, metal layered products, glass/slag layered products, etc., can solve problems such as cracking and breaking of insulating layers, poor toughness, and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

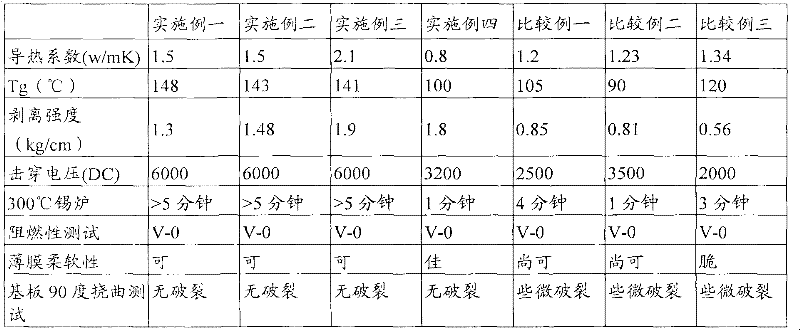

Examples

Embodiment 1

[0032] Add 60g phenoxy resin, 70g bisphenol A epoxy resin, 30g Albiflex 296, 25g F-351, 800g spherical alumina, 0.12g TPP-K, 50g NMA, 30g OP 935 and 5g Elvax 40W, to prepare the main agent of epoxy resin that has been dispersed.

Embodiment 2

[0034] Add 60g thermoplastic acrylic resin, 70g bisphenol A epoxy resin, 30g DA323, 30g Albiflex 296, 25g F-351, 500g alumina, 300g silicon carbide, 0.12g TPP-K, 50g NMA into a 1000mL reaction bottle , 40g OP 935 and 10g Elvax 40W to prepare the dispersed epoxy resin main agent.

Embodiment 3

[0036] Add 60g PI-216 resin, 70g bisphenol A epoxy resin, 30g Albiflex XP 544, 25g F-351, 800g alumina, 200g boron nitride, 0.12g TPP-K, 50g NMA into a 1000mL reaction flask , 45g SPB-100 and 15g Elvax 40W to prepare the dispersed epoxy resin main agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com