Manufacturing method for steel ingot of axle steel

A manufacturing method and axle steel technology, applied in the field of steel ingot manufacturing, can solve problems such as poor stability, and achieve the effects of improving fatigue resistance, easy control, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

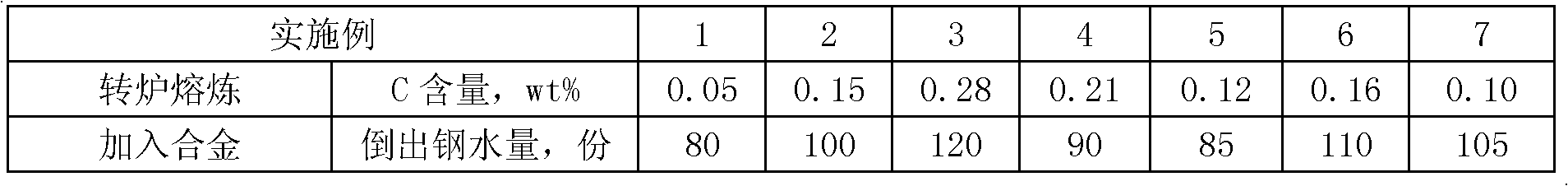

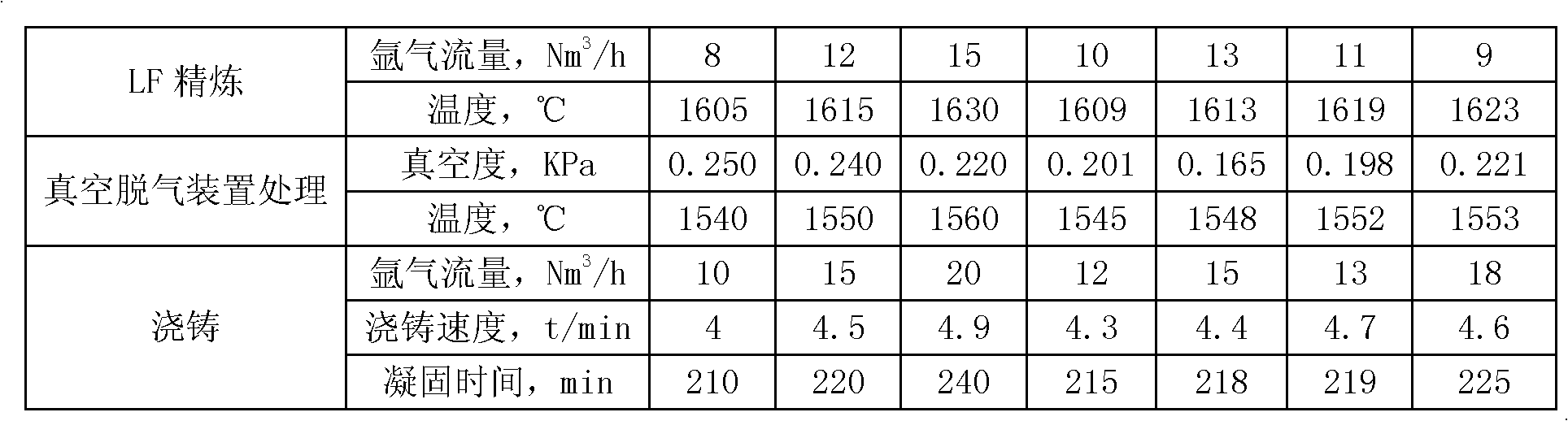

[0025] The concrete steps of manufacturing axle steel steel ingot are as follows (in embodiment 1-7, the addition of each raw material is shown in Table 1):

[0026] (1) Add 25-35 parts of steel scrap with Fe content ≥ 90wt% and 280-295 parts of molten iron with C content ≥ 3.8wt% and temperature ≥ 1200°C into the converter;

[0027] (2) Converter smelting: blowing in oxygen for smelting, when the C content in molten steel is 0.04-0.30wt%, and the molten steel temperature is 1660-1690°C, stop smelting;

[0028] (3) Add alloy: pour molten steel into the ladle; in the process of pouring out the molten steel, when 80 to 120 parts of the molten steel are poured out, add 1 to 1.5 parts of Si content ≥ 75wt% ferrosilicon alloy, 1.2 parts to the molten steel in the ladle ~1.6 parts of ferromanganese alloy with Mn content≥80wt%, 0.3~0.7 parts of aluminum-iron alloy with Al content≥50wt%, and 0.5~1.2 parts of carbon powder with C content≥99wt%;

[0029] (4) LF refining: Add 0.9-1.3 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com