Dredged and concealed waterproof (and heat-insulating) system

A technology of hidden heat insulation panels, applied in the direction of roof insulation materials, roof drainage, roofing, etc., can solve problems such as difficulty in recycling, high resource consumption, and failure to achieve ideal waterproof effects, etc., to achieve good ventilation performance and heat insulation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

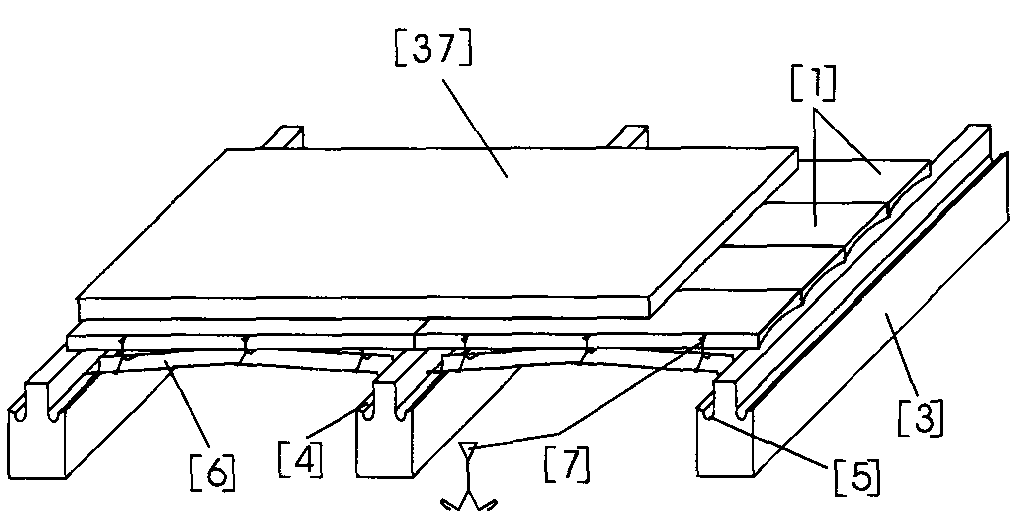

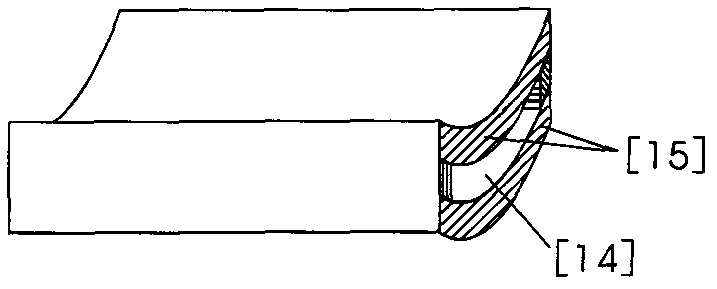

[0064] Example 1: Combining figure 1 , 22 , 23, 24, 25, 42, 43, the bottom surface of the waterproof heat shield [1] is processed into a smooth arc or ∧-shaped curved surface or inclined surface (curved surface or inclined surface can have Appropriate gradient), curved or ∧-shaped surfaces or slopes are all made of materials with strong hydrophilicity (or hydrophilicity after surfactant treatment), in order to make the waterproof heat insulation board [1] not under a large load If it is damaged, a supporting rib [2] with a suitable width and a height consistent with the arc or ∧ shape of the waterproof and heat insulating board [1] can be processed under the two ends of the waterproof and heat insulating board [1], such as Figure 23 As shown; the middle part of the load-bearing beam [3] protrudes to an appropriate height for carrying the waterproof and heat-insulating board [1], and U-shaped (or suitable structure) drainage ditches [5] are respectively processed on both side...

Embodiment 2

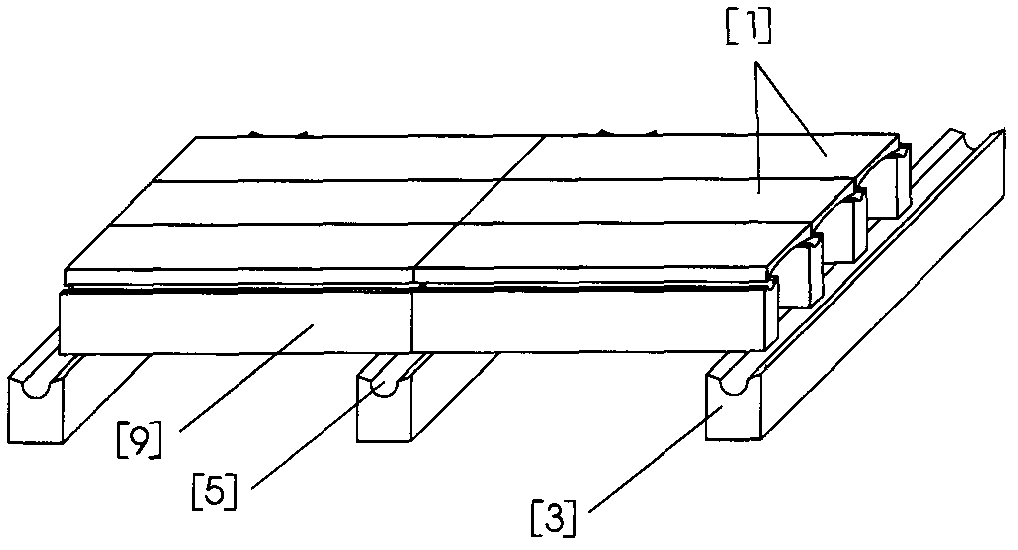

[0065] Example 2: Combining figure 2 , 26 , it is on the basis of embodiment 1, etc., the raised part of the load-bearing beam [3] is omitted, and the original U-shaped drainage ditch [5] on both sides is merged into the middle part, such as Figure 26 shown; and the processing structure is similar to the load-bearing beam, the side beam [9] with appropriate size replaces the U-shaped drainage channel [6], installs the two ends of the side beam [9] on the load-bearing beam [3], and makes the end Directly above the U-shaped drainage ditch [5], the waterproof and heat-insulating board [1] is installed on the side beam [9], and the lowest position of both sides is at the bottom of the U-shaped drainage groove [5] of the side beam [9]. directly above, such as figure 2 As shown, the waterproof and heat insulation system no longer uses U-shaped drainage grooves, and the drainage facilities are all hidden in the beams, which has a better appearance. When the distance between the ...

Embodiment 3

[0066] Example 3: Binding image 3 , 27 , 44, 45, it is on the basis of embodiment 2 etc., on the two side walls of side beam [9] inwardly excavate (or increase) the arc-shaped or ∧-shaped drainage ditch (or groove) of suitable size of quantity [11], when the U-shaped drainage ditch [5] of the side beam [9] is blocked or cannot completely drain the rainwater to the U-shaped drainage ditch [5] of the load-bearing beam [3], the arc or ∧-shaped drainage ditch [11 ] The overflowing rainwater is discharged to the U-shaped gutter [5] of the load-bearing beam [3] to complete the waterproof and heat insulation tasks. When processing the side beam [9], the gutter [11] can be used as Figure 44 As shown in the mold, make a suitable number of inserts [48] with pin holes for fixing on a mold [47] with a suitable radian or slope, and process inserts at the corresponding positions of the side molds [50] of the side beams [9] hole, when the mold is installed, pass the insert [48] through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com