Bearing wall reinforcing body and method for reinforcing bearing wall by using same

A load-bearing wall and reinforcement technology, which is applied in construction, building maintenance, building construction, etc., can solve the limitation of the improvement of the bearing capacity of the reinforced masonry, the weak bearing capacity of the masonry wall, and the weak resistance to deformation, etc. problems, to achieve the effect of improving the seismic performance, increasing the size of the masonry, and preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

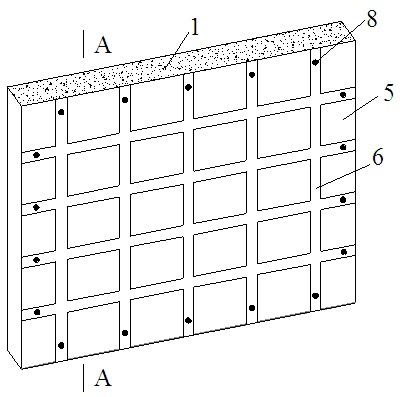

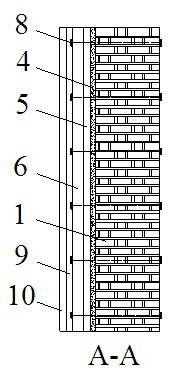

[0025] Below in conjunction with accompanying drawing, the present invention is further described: According to figure 1 , figure 2 As shown, a load-bearing wall reinforcement includes a rigid mesh layer, the rigid mesh layer is an expanded metal layer 6, and a fiber-reinforced polymer layer 5 is arranged on one side of the expanded mesh layer 6.

[0026] The other side of the steel mesh layer 6 is provided with a coarse quartz sand layer 9 .

[0027] The outside of the coarse quartz sand layer 9 is also provided with an anti-rust and decorative layer 10 .

[0028] The fiber reinforced polymer is carbon fiber reinforced polymer CFRP.

[0029] The steel mesh layer 6 is formed by welding longitudinal and transverse steel strips.

[0030] A method for reinforcing a load-bearing wall with a load-bearing wall reinforcement, the steps are as follows:

[0031] (1) Remove the decorative layer on the external surface of the load-bearing wall, drill and wash the load-bearing wall; ...

Embodiment 2

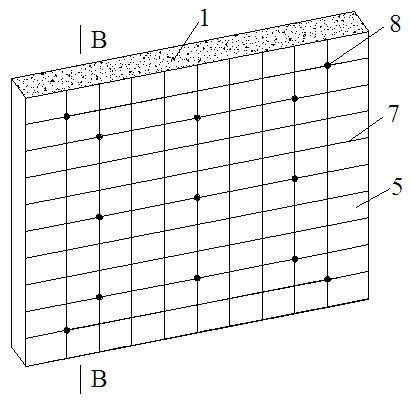

[0035] Below in conjunction with accompanying drawing, the present invention is further described: According to image 3 , Figure 4 As shown, a load-bearing wall reinforcement includes a rigid mesh layer, the rigid mesh layer is a reinforcement mesh layer 7, and a fiber-reinforced polymer layer 5 is arranged on one side of the reinforcement mesh layer 7.

[0036] The other side of the reinforcement mesh layer 7 is provided with a coarse quartz sand layer 9 .

[0037] The outside of the coarse quartz sand layer 9 is also provided with an anti-rust and decorative layer 10 .

[0038] The fiber-reinforced polymer is aramid fiber-reinforced polymer AFRP.

[0039] The reinforcement mesh layer 7 is formed by welding longitudinal and transverse reinforcement.

[0040] Screw rods are welded at the reinforcing bar intersections of the reinforcing mesh layer 7 .

[0041] A method for reinforcing a load-bearing wall with a load-bearing wall reinforcement, the steps are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com