Electromagnetic acoustic emission non-destructive testing method for non-ferromagnetic metal sheet and device adopting same

A metal sheet, non-destructive testing technology, applied in the direction of material magnetic variables, etc., can solve the problems of extracting materials, difficulty, and inability to detect activity status information, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

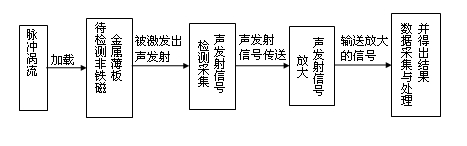

Method used

Image

Examples

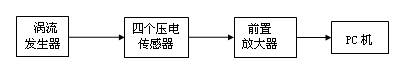

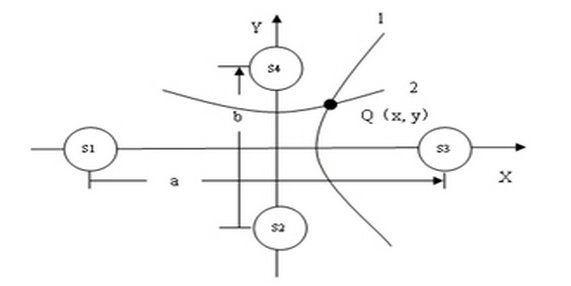

Embodiment 1

[0032] When starting to detect, the signal generator output control signal in the eddy current generator is 2 cycles, the frequency is 5kHz and the square wave voltage of voltage is 8V, and this signal is input to the power amplifier connected to the 190V DC power supply in the eddy current generator, the power The amplifier generates a pulse voltage with the same frequency and equal number of cycles as the control signal and a voltage of 190V. The pulse square wave voltage is loaded on the circuit composed of the resonant capacitor and the exciting coil, and is tested in a 500mm×115mm×15mm A quasi-sinusoidal eddy current with 2 cycles and a frequency of 5kHz is induced on the aluminum sheet. If there is a crack in the aluminum sheet to be detected, an acoustic emission signal will be excited, and the acoustic emission signal is detected by four piezoelectric sensors S 1 , S 2 , S 3 and S 4 It is detected and input to the preamplifier through the signal line, the acoustic em...

Embodiment 2

[0037] The output control signal of the signal generator in the eddy current generator is 5 cycles, the frequency is 10kHz and the pulse square wave voltage is 8V. The non-ferromagnetic metal sheet to be detected is a copper metal sheet to be detected with a size of 500mm×115mm×15mm Except, other are all the same as embodiment 1.

[0038] The position of the crack defect in the copper metal sheet to be detected is detected by the final positioning, and the positioning error is 1-2mm.

Embodiment 3

[0040] The output control signal of the signal generator in the eddy current generator is 3 cycles, the frequency is 7.5kHz and the pulse square wave voltage is 380V. Except the copper metal sheet, others are all the same as embodiment 1.

[0041] The position of the crack defect in the copper metal sheet to be detected is detected by the final positioning, and the positioning error is 1-2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com