TO247 lead frame

A technology of TO247 and lead frame, which is applied in the field of semiconductor device packaging, can solve the problems of reducing the poor performance of stress release and the inability to effectively control the void rate of products, so as to increase the bonding fastness of mounting, release internal stress, and resist external stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments.

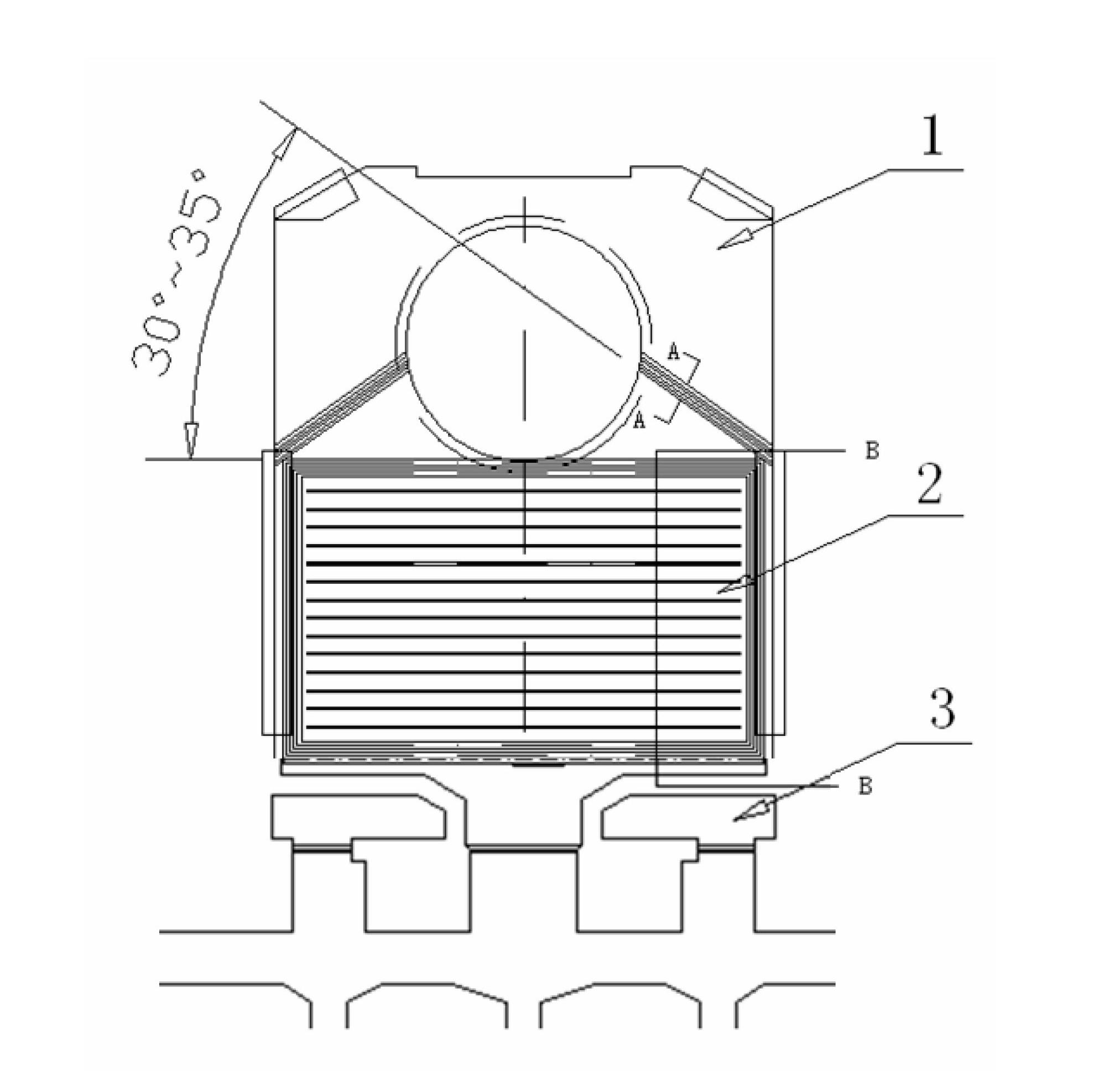

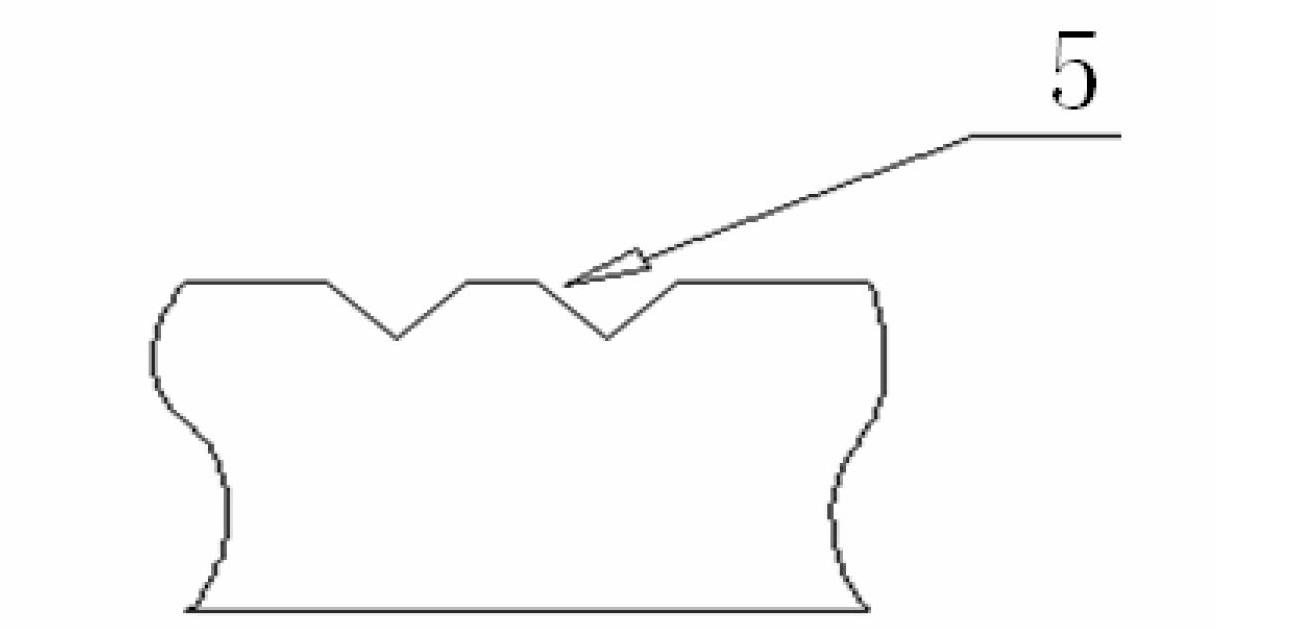

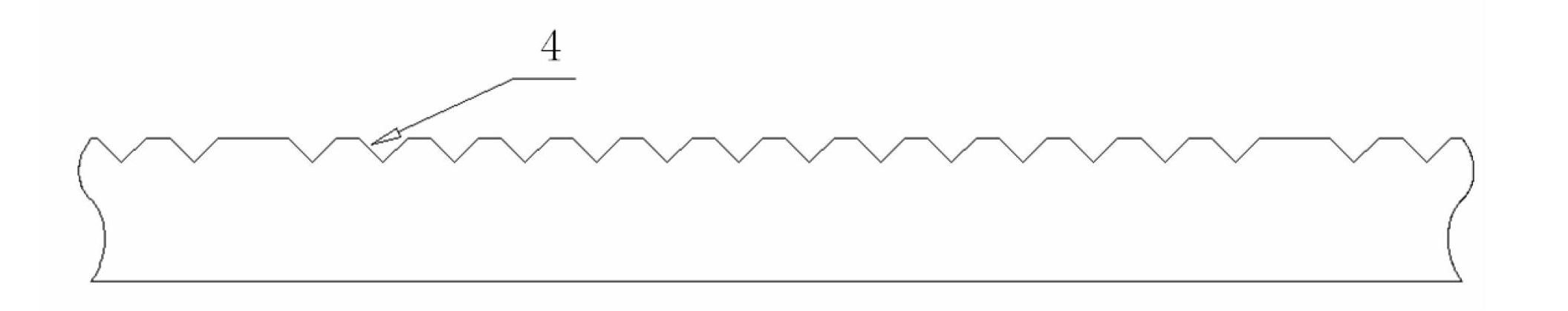

[0019] Such as figure 1 As shown, a TO247 lead frame includes a heat sink 1 and three pins 3 connected below the heat sink 1. The upper area of the heat sink 1 is the heat sink hole 6, and the lower area is the heat sink base. Island 2, the upper area of the heat dissipation plate 1 is provided with a number of oblique second slots 5 symmetrically on both sides of the round hole 6 of the heat dissipation plate, and a number of first slots 4 are provided around and inside the base island 2 of the heat dissipation plate , The second slot 5 at the end connects the heat dissipation plate circular hole 6 and the first slot 4 on the upper periphery respectively, and the trajectory of each of the second slot 5 and the transverse track of the first slot 4 on the upper periphery Match at an angle of 30 to 35 degrees.

[0020] Chips are mounted in the base island 2 of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com