Method for producing tea extract

A manufacturing method and extract technology, which is applied in the field of tea extract manufacturing, can solve problems such as difficulty in obtaining aroma, and achieve the effect of less miscellaneous taste, strong taste, and comfortable taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

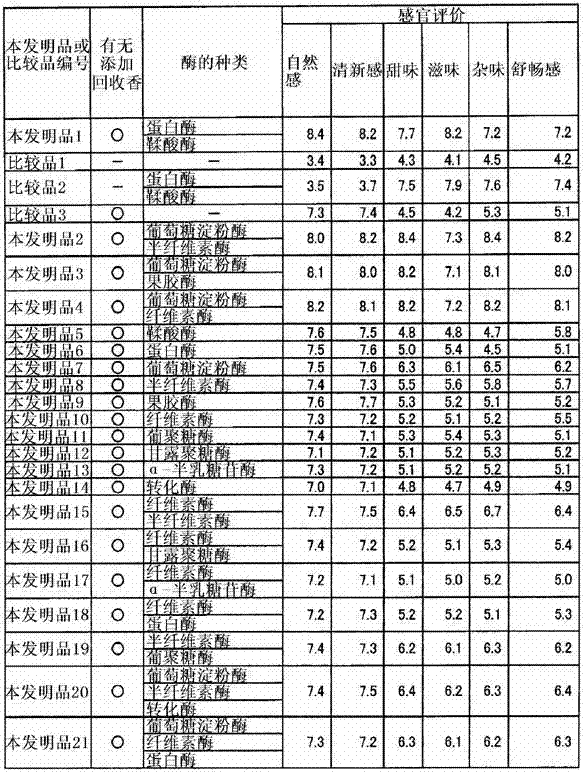

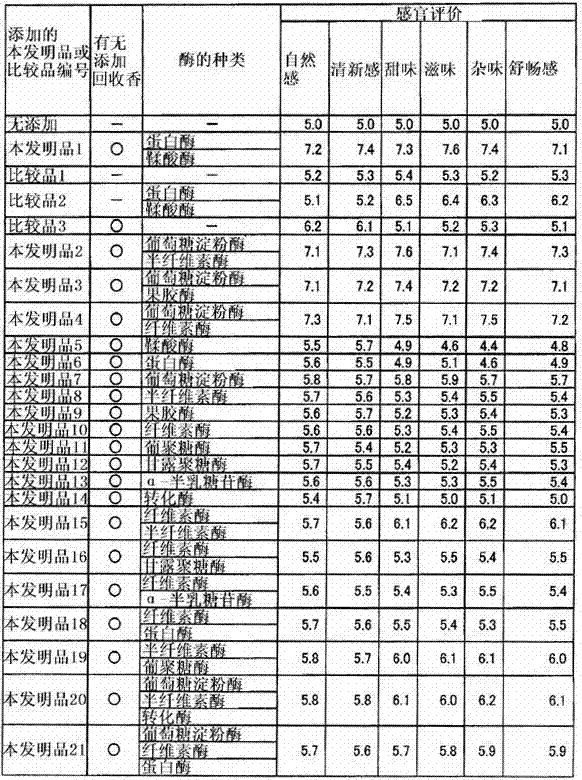

Examples

Embodiment 1

[0058] (Example of aroma recovery from green tea by gas-liquid countercurrent contact extraction, protease and tannase treatment of distillation residue)

[0059] Grind 40 kg of commercially available Ichibancha from Shizuoka using a hammer mill (mesh 1.2 mm), add 360 kg of water in which 0.24 kg of sodium ascorbate was dissolved, make a slurry, and use the gas-liquid countercurrent contact extraction method under the following conditions 16 kg of recovered incense (40% relative to green tea) was obtained (hereinafter referred to as recovered incense (a)).

[0060] Device: SCC Model 1000 (manufactured by フレーバーテック)

[0061] processing conditions

[0062] Raw material supply speed: 700L / Hr

[0063] Steam flow: 55kg / hr

[0064] Strip speed: about 4%

[0065] Tower bottom temperature: 100°C

[0066] Tower upper temperature: 100°C

[0067] Vacuum: Atmospheric pressure.

[0068] Cool 400kg of residue slurry (equivalent to 40kg of green tea) (hereinafter referred to as residue s...

Embodiment 2

[0079] (Example of replacing the enzyme of Example 1 with glucoamylase and hemicellulase)

[0080] In Example 1, 2 g of Sumizyme (glucoamylase activity 2,000 U / g; glucoamylase manufactured by Shin Nippon Chemical Industries, Ltd.) and 2 g of Sumizyme X (hemicellulase manufactured by Shin Nippon Chemical Industries, Ltd.) were used as enzymes, except Otherwise, the same operation as in Example 1 was performed to obtain 325.8 g of a Bx35° green tea extract (this invention product 2) (pH 5.3, yield 162.9% relative to green tea).

Embodiment 3

[0082] (Example of replacing the enzyme of Example 1 with glucoamylase and pectinase)

[0083] In Example 1, 2 g of Sumizyme (glucoamylase activity 2,000 U / g; glucoamylase manufactured by Shin Nippon Chemical Industry Co., Ltd.) and 2 g of Sukraze N (pectinase manufactured by Mitsubishi Chemical Fuss Co., Ltd.) were used as enzymes. Exactly the same operation as in Example 1 was performed to obtain 328.4 g of a Bx35° green tea extract (product 3 of the present invention) (pH 5.3, yield relative to green tea: 164.2%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com