Gas supply device

A gas supply and gas technology, applied in the direction of gas processing applications, gas processing/storage purposes, container structure installation devices, etc., can solve the problems of gas temperature reduction, difficult gas pressure adjustment, etc., to reduce energy and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

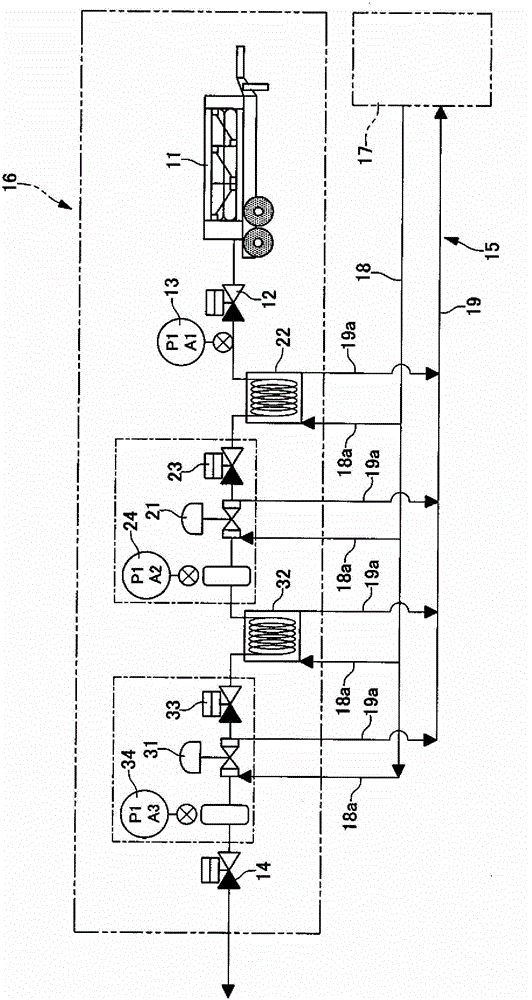

[0020] The gas supply device shown in this embodiment is provided with two pressure regulators 21, 31 in series as a decompression unit for reducing the pressure of the gas supplied from the high-pressure gas container 11. The high-pressure gas container 11 is a compressed gas supply source filled with compressed gas at a predetermined high pressure; and it is formed so that the high-pressure gas is decompressed at a predetermined decompression degree by the first pressure regulator 21 that uses the gas flow to the upstream side. As the medium-pressure gas, the medium-pressure gas is decompressed at a predetermined decompression degree by the second pressure regulator 31 on the downstream side, and the low-pressure gas at the pressure required by the supply destination is supplied. For example, in the case of depressurizing and supplying compressed gas having a filling pressure of 9 MPa (absolute pressure, hereinafter the same) to near atmospheric pressure, after depressurizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com