Petroleum coke crusher

A technology of crusher and petroleum coke, which is applied in the direction of grain processing, etc., to achieve the effect of large space, small resistance and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A specific implementation of a petroleum coke crusher will be described in detail below in conjunction with the accompanying drawings.

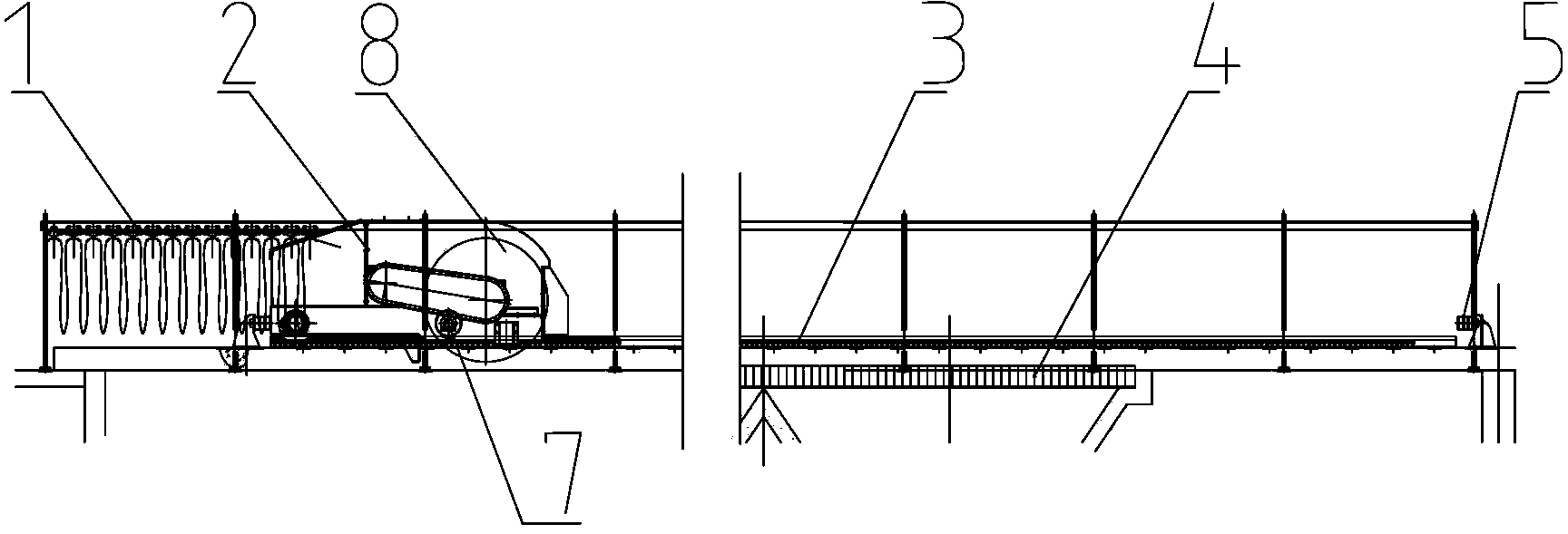

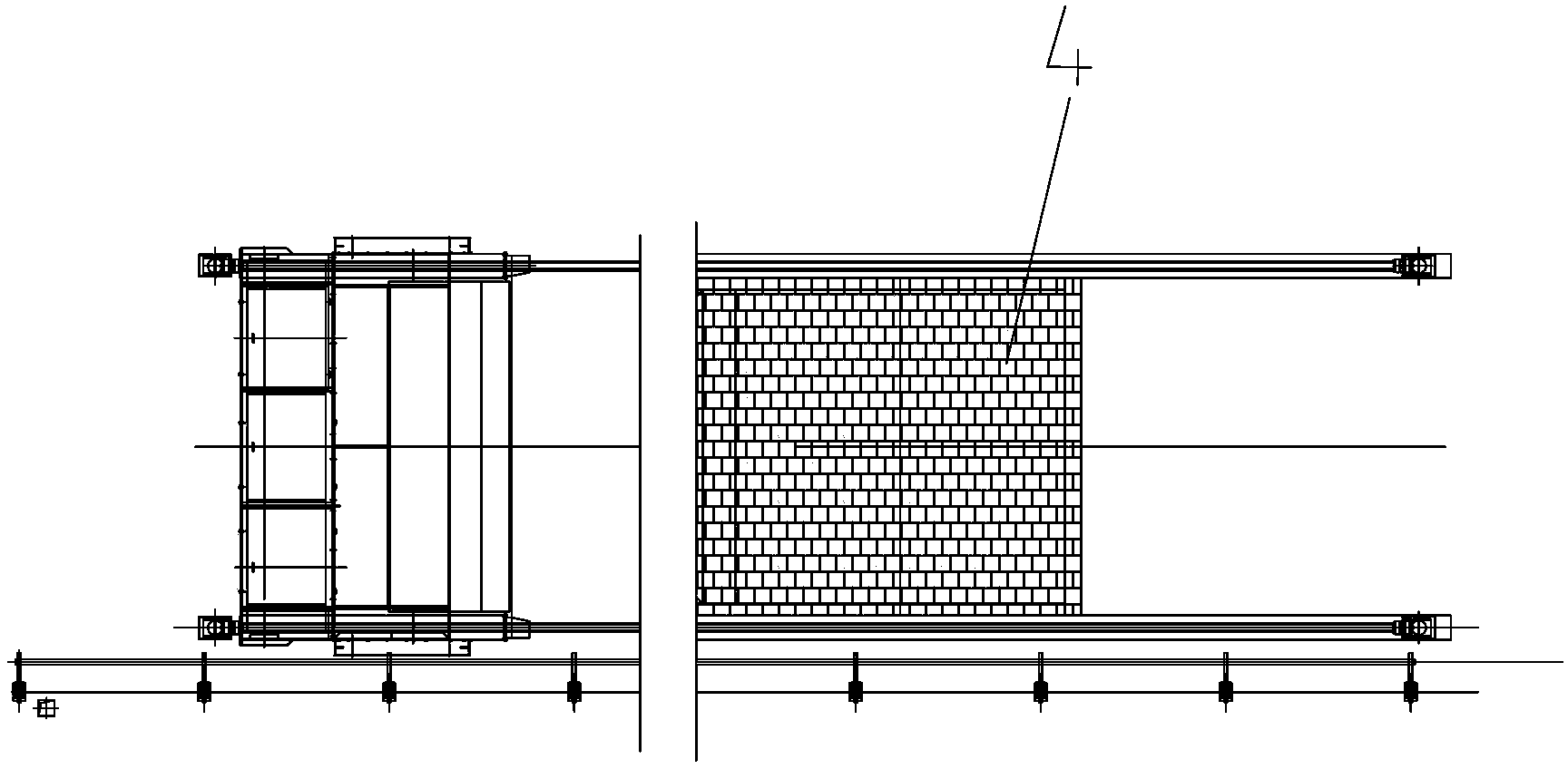

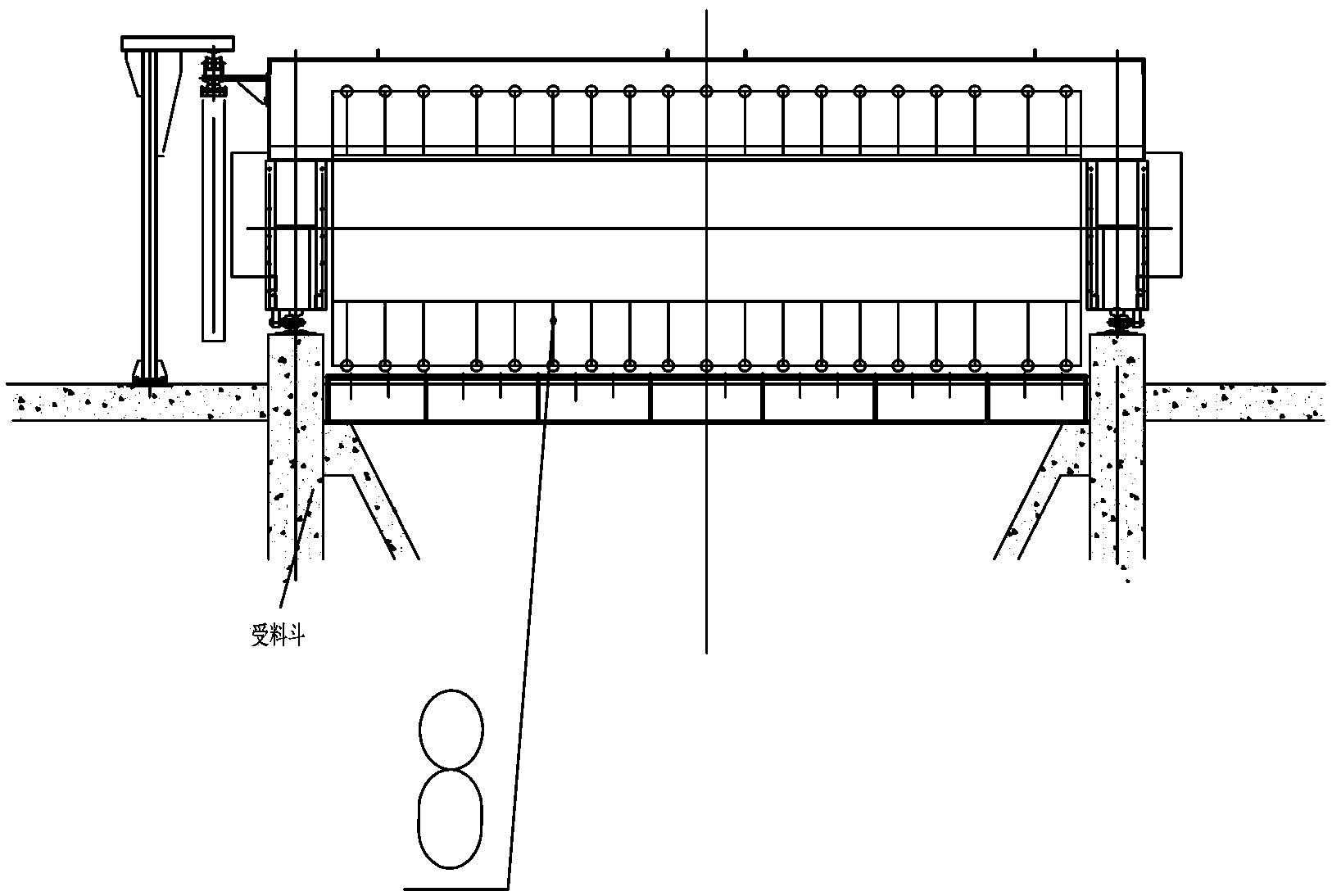

[0047] A petroleum coke crusher comprises: a cable pulley device 1, a frame 2, a track 3, a grate body 4, a buffer stopper 5, an electric control system 6, a traveling transmission system 7 and a crusher main body 8.

[0048] The grate body 4 is installed on the receiving hopper, the track 3 is installed on a raised cement beam higher than the plane of the receiving hopper and the grate body 4, the buffer stopper 5 is installed at both ends of the track 3, and the travel transmission system 7 It is installed on the track 3 and moves along the track. The bottom of the frame 2 is equipped with a traveling transmission system 7. The main body of the crusher 8 is installed on the frame 2. The main body of the crusher 8 cleans and breaks petroleum coke during the movement, and passes through the cables installed on the foundation. The shift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com