Chopstick polishing equipment with sorting function

A chopsticks and sorting technology, applied in grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., to achieve the effects of low manufacturing cost, simple structure and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

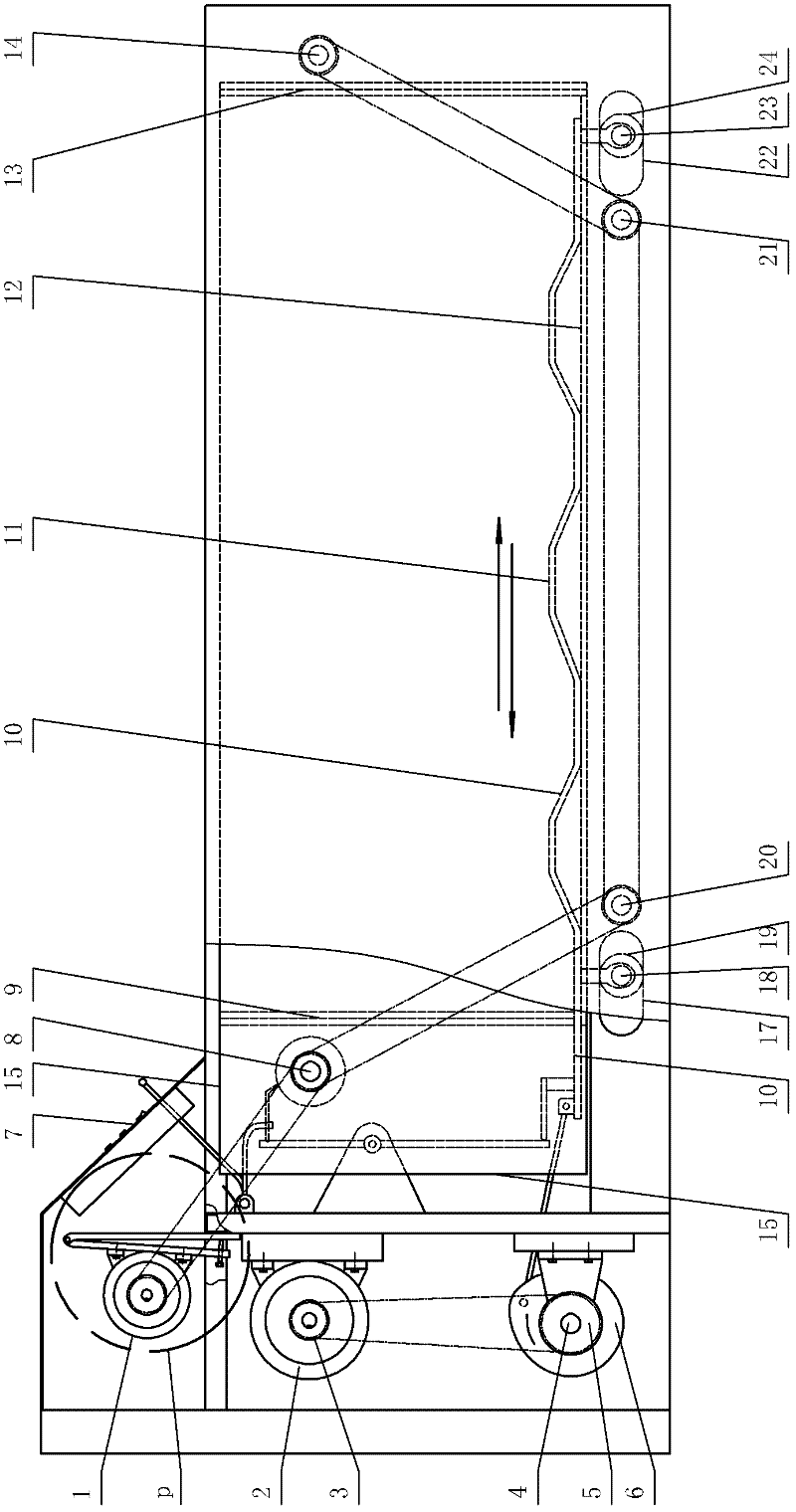

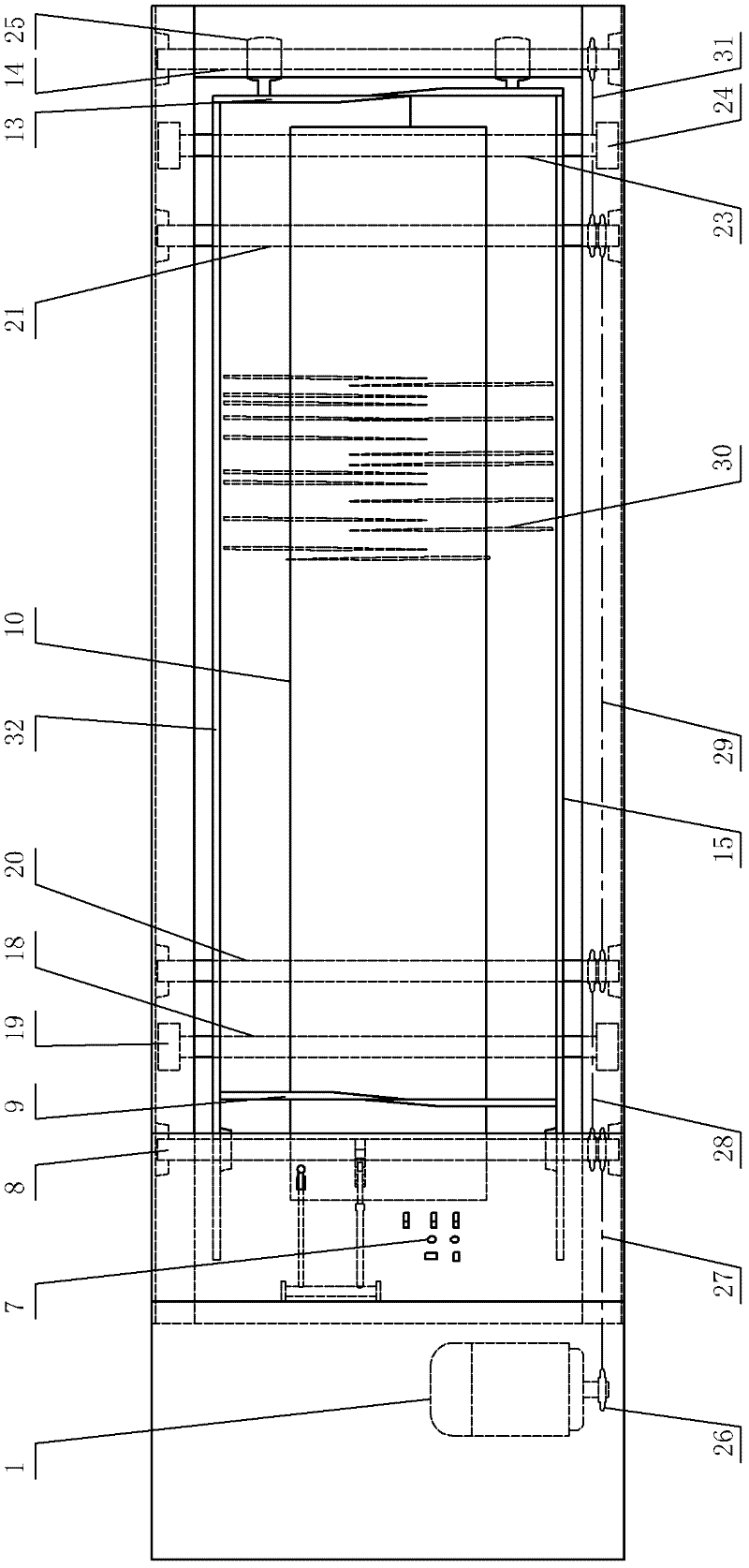

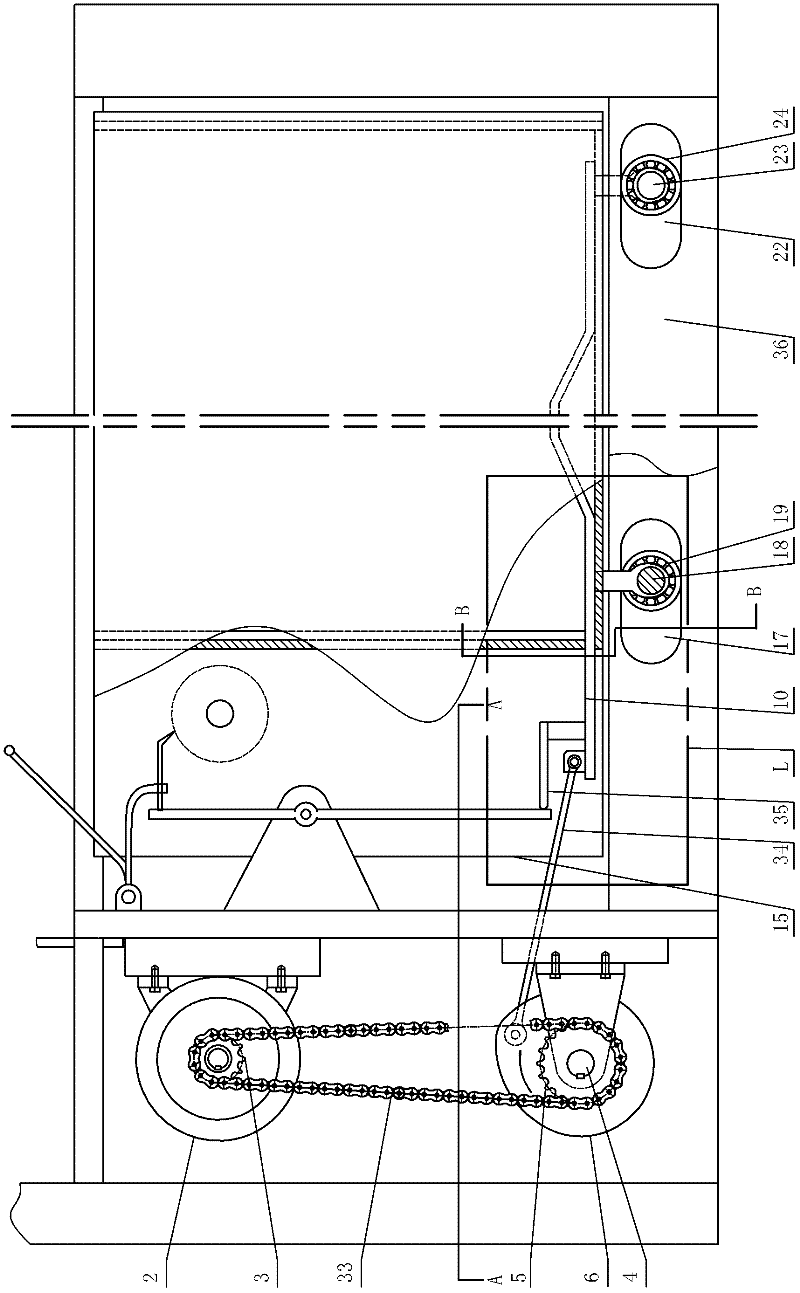

[0027] The device of the present invention will be further described below in conjunction with a specific embodiment.

[0028] refer to Figure 1-6 , the main part of the polishing equipment shown in this example is a rectangular tank structure, the front end is a box structure, and a control panel 7 is arranged above the front end. The main part is provided with a polishing groove, and a polishing curved plate 10 is arranged in the polishing groove. The front-end box structure is respectively provided with a reset motor 1, a main motor 2, and a main shaft 4 from top to bottom, the output shaft of the main motor 2 is equipped with a first sprocket 3, and one end of the main shaft 4 is installed with a Cam 6, the other end is equipped with second sprocket wheel 5. The second sprocket 5 and the first sprocket 3 are connected by a first transmission chain 33 . A short shaft 37 is provided at a non-axial position on one side of the cam 6 . One end shaft hole of a connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com