Fully-electric ultra-high speed injection molding PVT (Pressure Volume Temperature) online measurement and control method

A technology of injection molding, measurement and control method, which is applied in the field of ultra-high-speed injection molding measurement and control to achieve the effect of high control precision and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

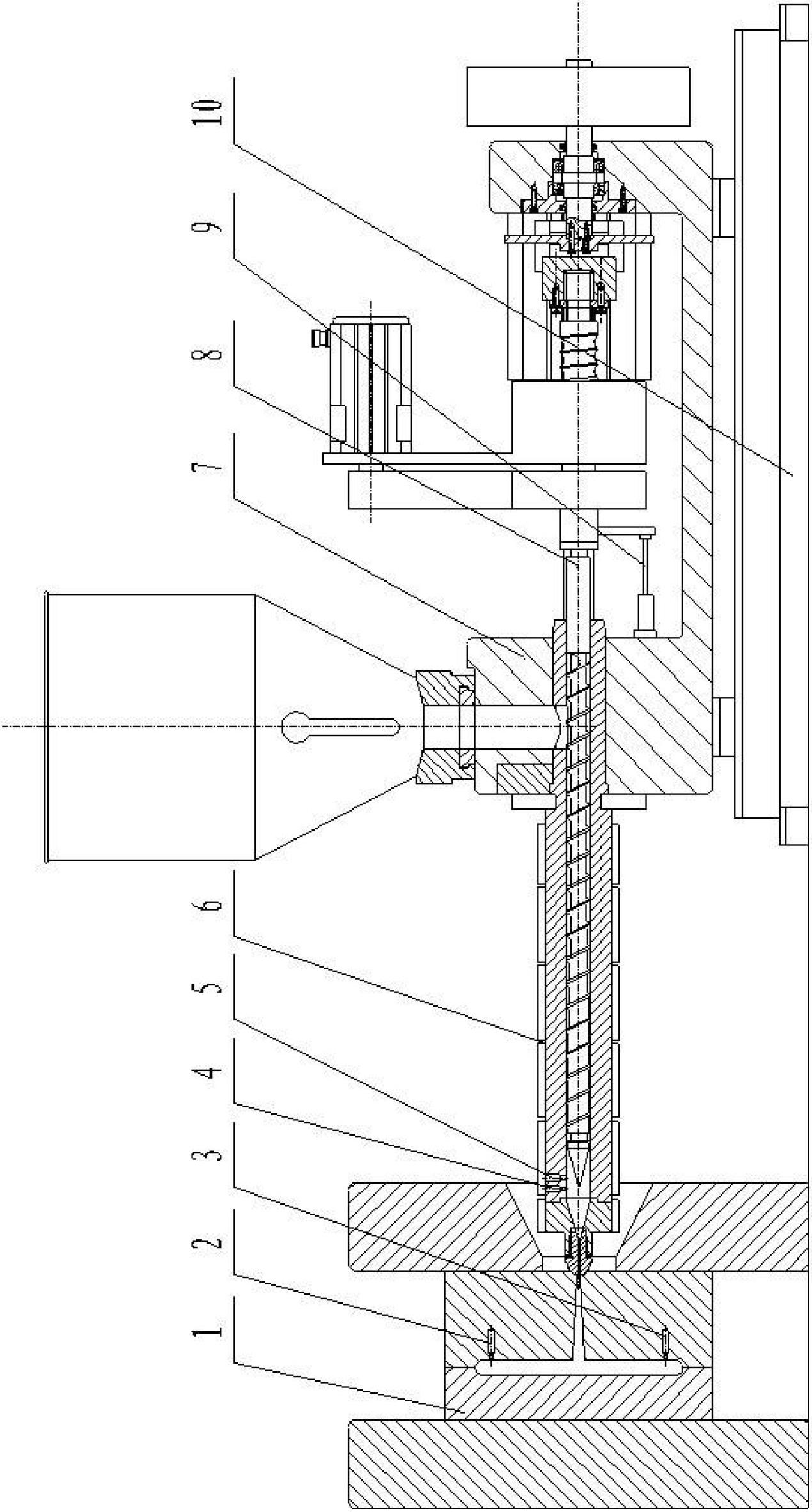

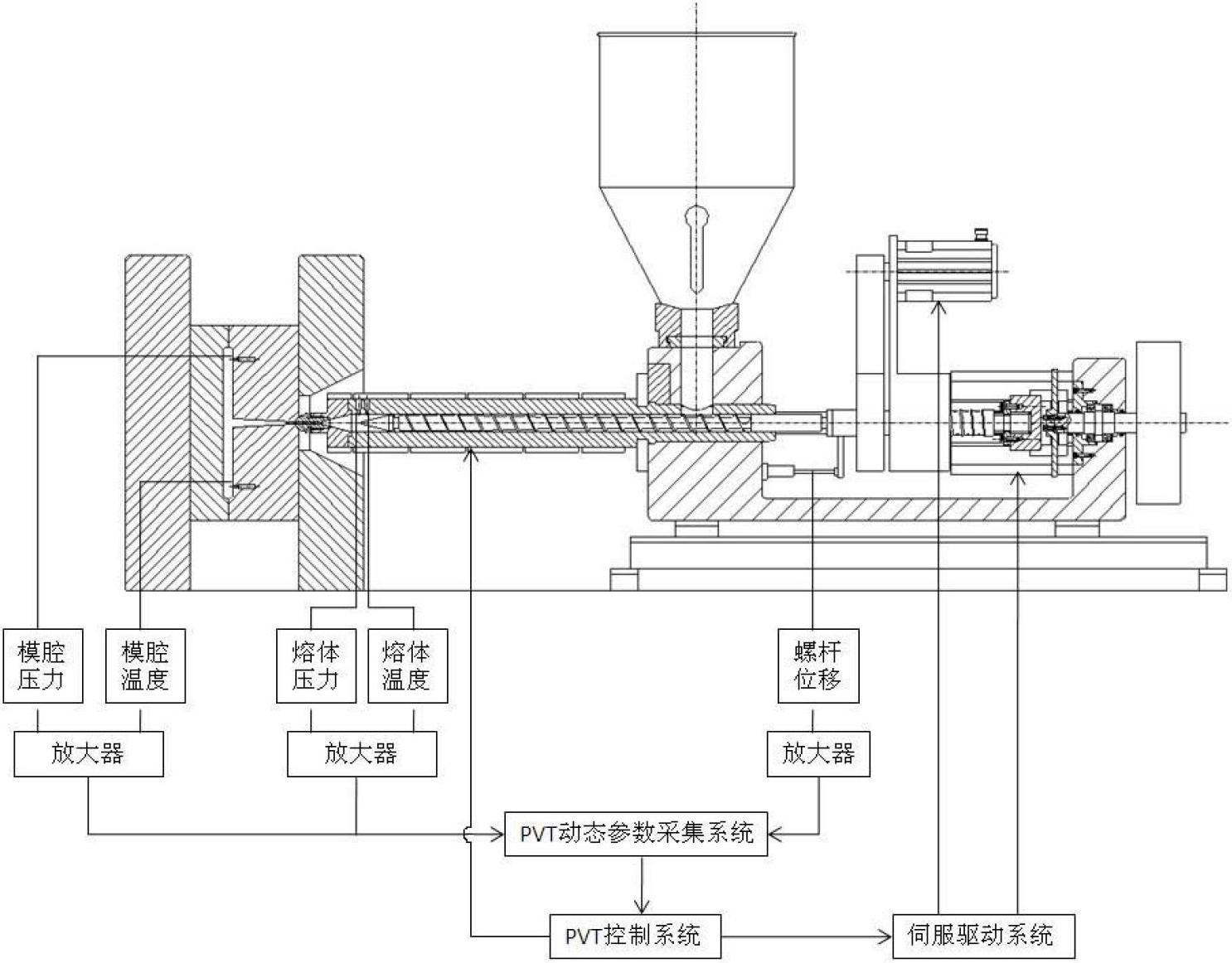

[0019] Such as figure 1 As shown, the test scheme of the all-electric ultra-high-speed injection molding PVT online measurement and control method of the present invention is mainly composed of an injection mold 1, an injection system 7 and a frame 10; a mold high-precision temperature sensor 2 and a mold high-precision pressure sensor 3 are installed on the injection mold In the cavity of the mold 1, the temperature and pressure in the cavity are detected; the barrel high-precision temperature sensor 4 and the barrel high-precision sensor 5 are installed at the front end of the barrel 6 to detect the temperature and pressure of the melt at the head of the barrel; displacement The sensor 9 is arranged at the end of the injection screw 8 to detect the position of the screw.

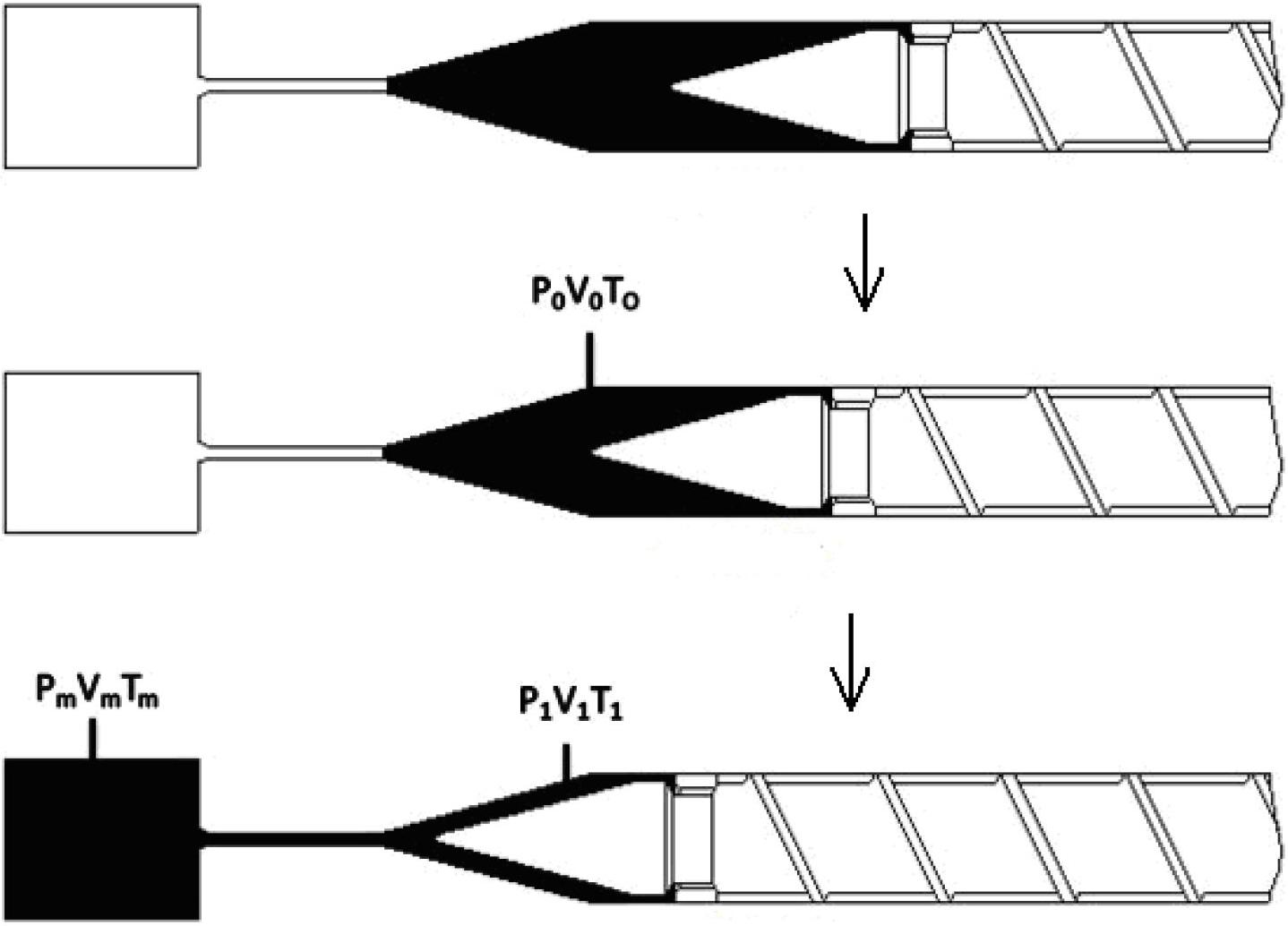

[0020] Such as figure 2 As shown, the control principle of the all-electric ultra-high-speed injection molding PVT online measurement and control method of the present invention is to use the melt after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com