Self-adaptive adjustable low-resistance fairing

A fairing, adjustable technology, applied in the field of self-adaptive adjustable low-resistance fairing, to achieve the effect of reducing flight resistance, small frictional resistance, and pressure difference reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

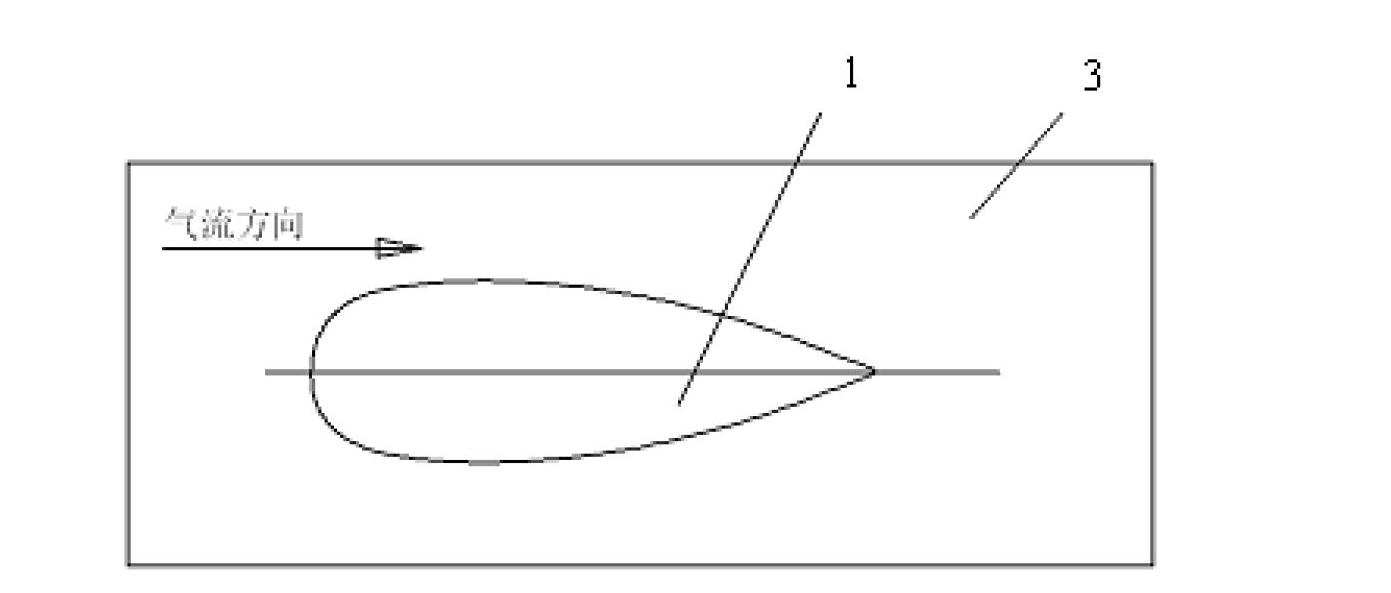

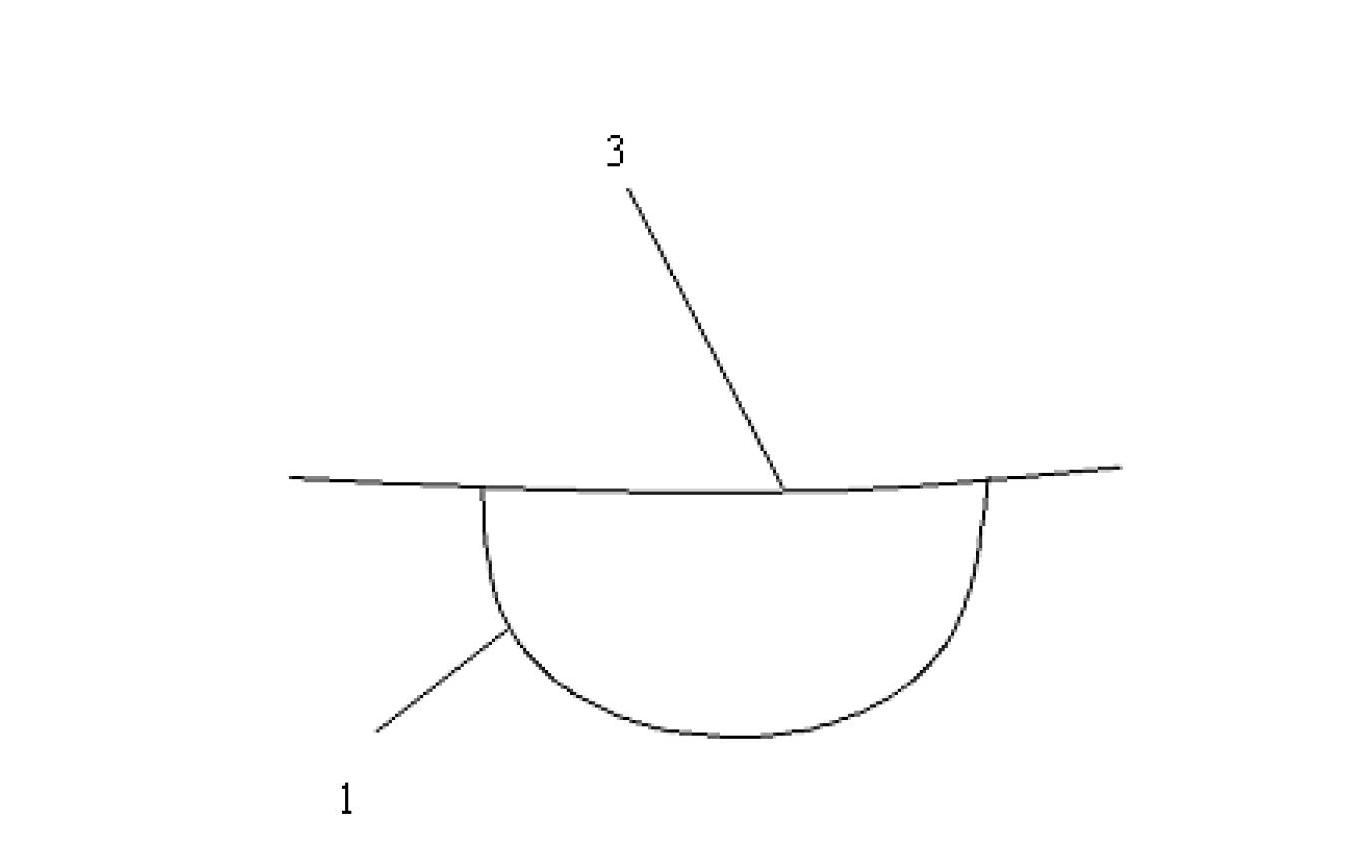

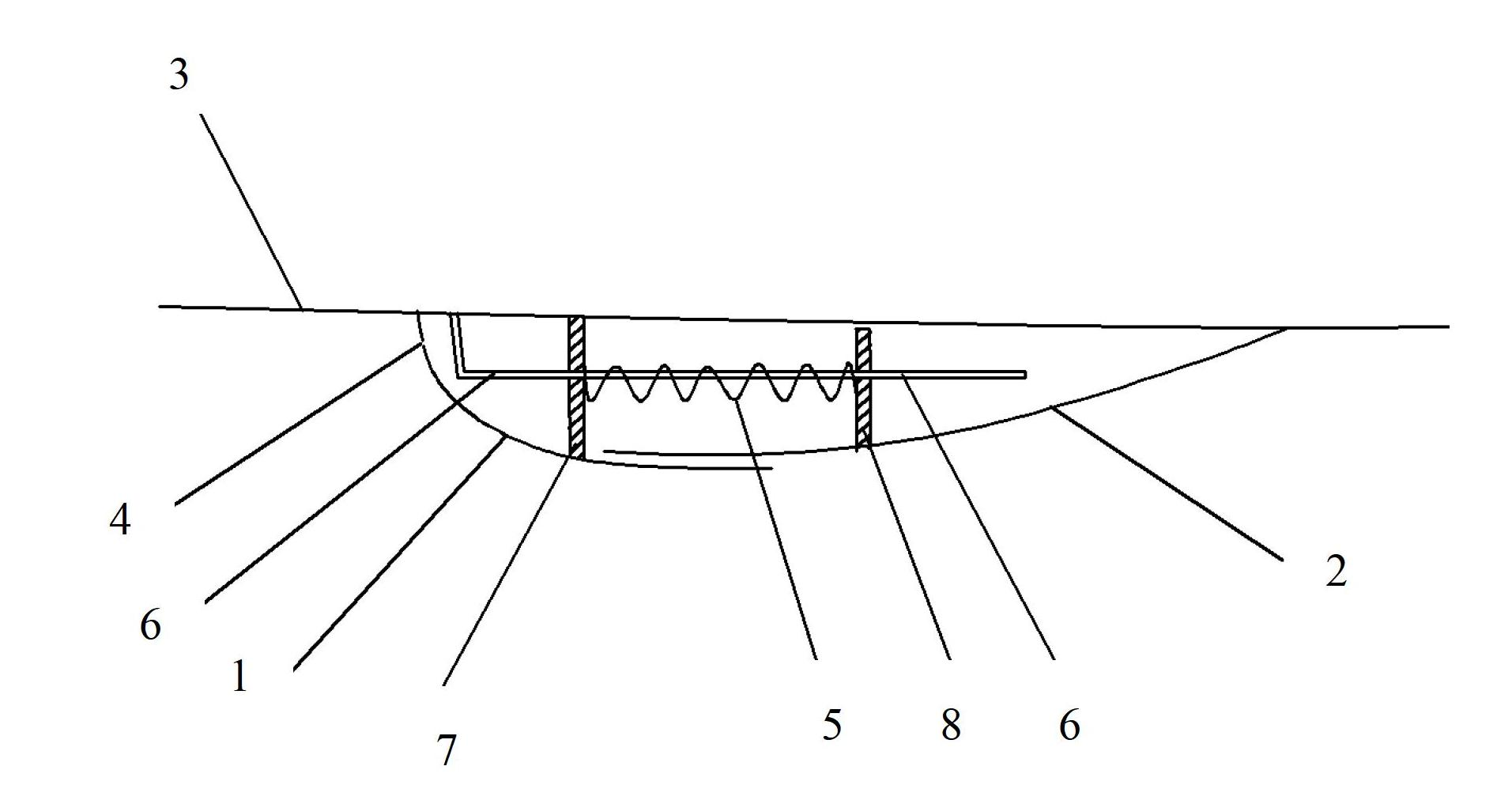

[0015] In one embodiment of the present invention, the existing fairing is improved. The existing fairing adopts a raindrop-shaped head and a wedge-shaped tail with a total length of 800 mm. The fairing is divided into two parts at a distance of 300 mm from the front end of the fairing. , that is, the head of the fairing 1 and the rear part of the fairing 2.

[0016] The head of the fairing is fixedly riveted on the surface of the aircraft body, and a through hole is left near the stagnation point of the air flow at the front end of the head of the fairing. , the front end of the fixed slide rail is fixed on the surface of the body, and passes through the front end plate in the direction of airflow, and is welded firmly with the front end plate. There is a proper gap between the inner cavity of the cowl head and the inner wall of the fairing head, which can ensure sliding without resistance. There is a 5mm gap between the rear of the fairing and the surface of the body, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com