Bidirectional moving aloft working material lifting device

A high-altitude operation and two-way moving technology, applied in safety devices, transportation and packaging, trolley cranes, etc., can solve problems such as difficult operation, poor stability, and high equipment height, and achieve accurate and reliable operation, low absolute height, and low labor load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

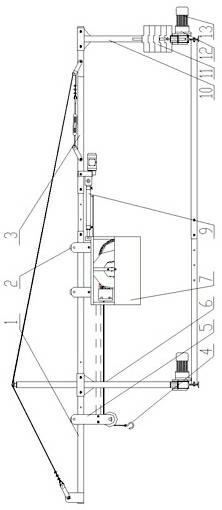

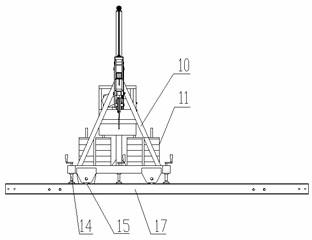

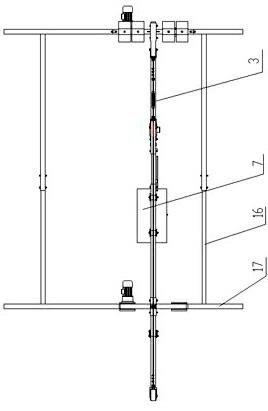

[0015] Combine below Figure 1~3 The views of the three directions of , illustrate the specific structure of the device of the present invention.

[0016] Such as figure 1 with image 3 , the two-way moving high-altitude material hoisting device of the present invention, the front beam 1 is a part of the suspension hoist assembly 7 and the guide wheel assembly 5, both of which are suspended above by the pulley 2 and can move on the front beam 1; And fix with connecting rod 8, keep the synchronous movement of both, this movement is longitudinal. Specifically, the hoist assembly 7 is a hoist with a rope retractor, and a weight sensor is also arranged on it. An electric push rod 9 is arranged on the hoist assembly 7, and the fixed end of the electric push rod 9 is fixed on the front beam 1. In this way, by pushing the electric push rod 9, the front and rear directions of the hoist assembly 7 and the guide sheave assembly 5 can be controlled. (Promptly longitudinal) move, unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com