Ultrasonic demulsification device for rendering of scouring wastewater

A technology of wool scouring wastewater and demulsification device, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problems of low recovery rate, large acid consumption, and large solvent loss and other issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

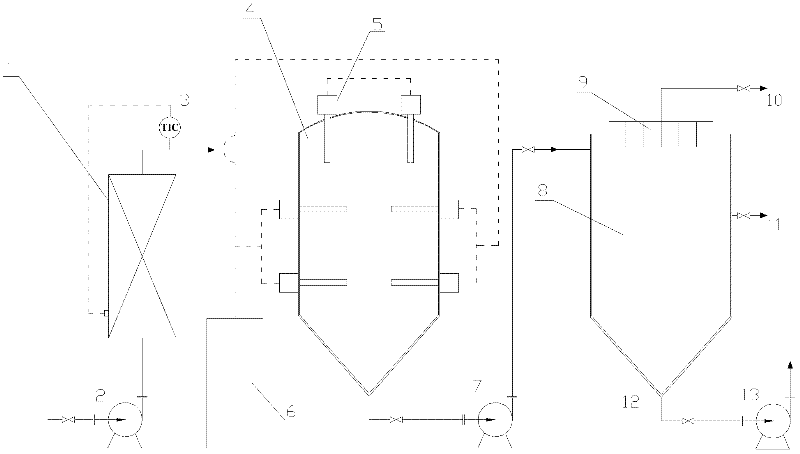

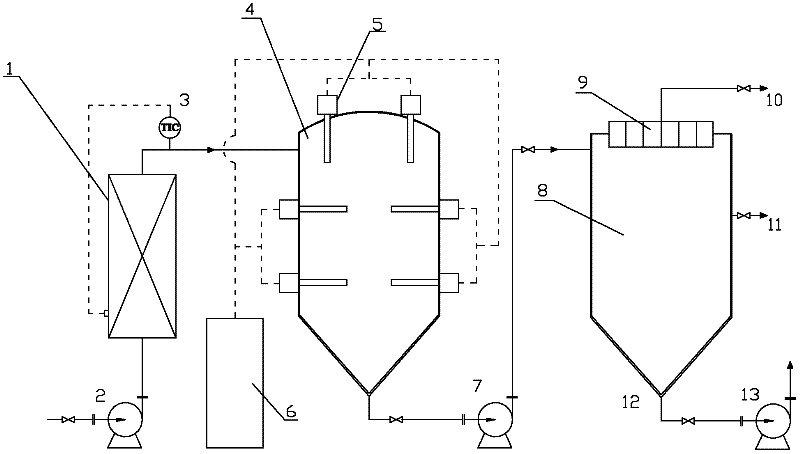

[0016] refer to figure 1 , an ultrasonic demulsification device for fat-lifting wool-scouring waste water, comprising: a preheater 1 with a temperature control device 3, a sewage pump 2 for transporting wool-scouring waste water to the pre-heater 1, and a pump behind the pre-heater 1 Ultrasonic radiation tank 4, ultrasonic generator 5 distributed on the radiation tank 4, controller 6 for controlling the ultrasonic generator, sewage pump 7 arranged at the outlet of the bottom of the radiation tank 4, settling tank 8 for wastewater settlement after radiation, The oil skimmer 9 arranged on the top of the settling tank 8, the grease outlet 10 of the oil skimmer 9, the drain port 11 in the middle of the settling tank 8, the sludge discharge port 12 at the bottom of the settling tank 8, and the sludge pump 13 connected to the sludge discharge port 12. Wherein, both the tank body of the ultrasonic radiation tank and the tank body of the settling tank can be cylindrical, and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com