Cement grinding aid

A kind of cement grinding aid and grinding aid technology, applied in the field of cement grinding aid, can solve the problems of difference in effect, harm of cement or concrete, etc., and achieve the effects of saving power consumption, reducing consumption and improving cement strength

Inactive Publication Date: 2012-08-22

安徽省振华工贸股份有限公司

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Even if the same product from different manufacturers is applied to different manufacturers, there are cases where the effect is quite different

Existing products cannot give full play to the product’s effect of improving the adhesion of grinding materials, and fail to combine various effective grinding aid ingredients together to achieve the best grinding effect. At the same time, chlorine or alkali in existing grinding aids will Hazardous to cement or concrete

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

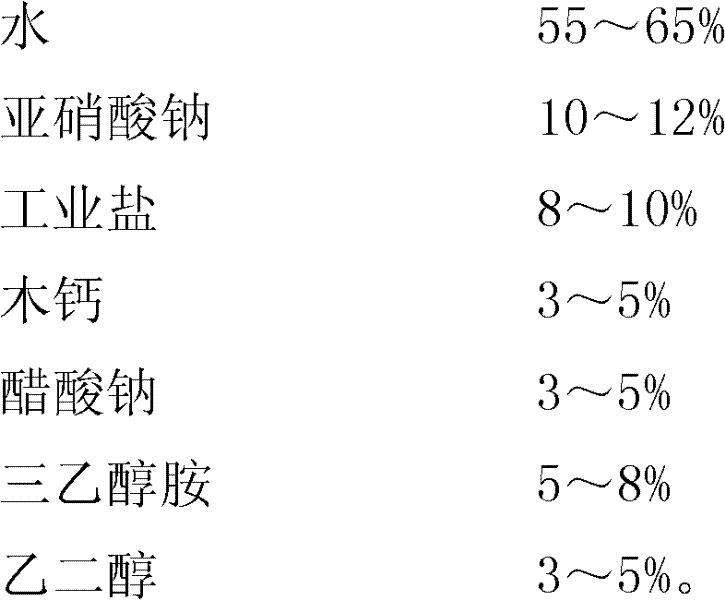

Embodiment 1

[0013] A kind of cement grinding aid formula:

[0014]

[0015]

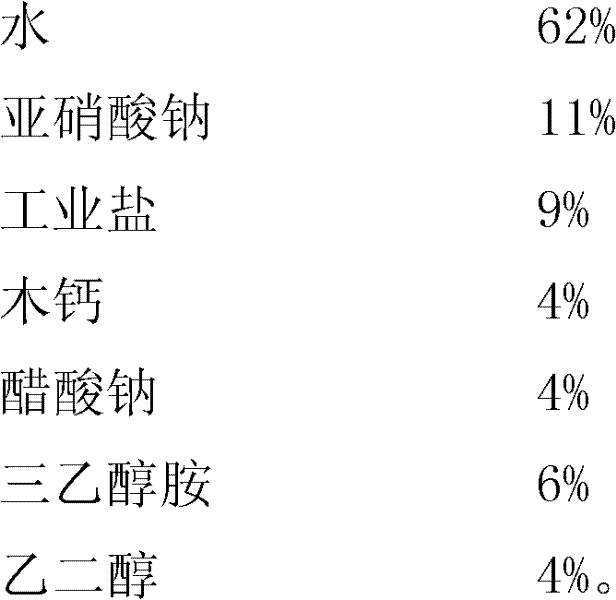

Embodiment 2

[0017] A kind of cement grinding aid formula:

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a cement grinding aid, and relates to the field of cement production technology. The cement grinding aid comprises components by mass percent: 55-65% of water, 10-12% of sodium nitrite, 8-10% of industrial salt, 3-5% of calcium lignosulphonate, 3-5% of sodium acetate, 5-8% of triethanolamine and 3-5% of glycol. After the cement grinding aid is adopted, the quality and the performances of cement are improved while the power consumption is saved; the performances of the cement reach the level of the performances of foreign similar products, and the cost and the price of the cement are lower than those of the foreign similar products; and the dosage of cement clinker is reduced, and the cement strength can be improved.

Description

Technical field: [0001] The invention relates to the technical field of cement production, in particular to a cement grinding aid. Background technique: [0002] Since the thirties in the 20th century, Englishman Goddard has obtained a patent with resin as a grinding aid. People have tested grinding aids such as acetic acid, phosphate, lignosulfonate, ethylene glycol, phenol, triethanolamine, tung oil and asphalt successively again subsequently. In the 1960s, industrial developed countries such as Japan, the United States, Germany, and the former Soviet Union researched and applied grinding aids more and more widely. In some developed countries, almost all cement plants used grinding aids. The research and utilization of grinding agents started relatively late. In the late 1950s, only a few cement plants tried to use coal, paper pulp waste liquid, and soap waste liquid, and the effect was not obvious; at present, the domestic research and application of cement grinding aids...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B24/18C04B103/52

Inventor 胡英臣葛永

Owner 安徽省振华工贸股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com