Preparation method of porous composite pearlstone heat preservation material

A thermal insulation material, perlite technology, applied in the direction of thermal insulation, ceramic products, building components, etc., can solve the problems of increasing product limitations, reducing thermal insulation effect, and easily damaged materials, so as to save raw material consumption, reduce finished product density, good scientific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

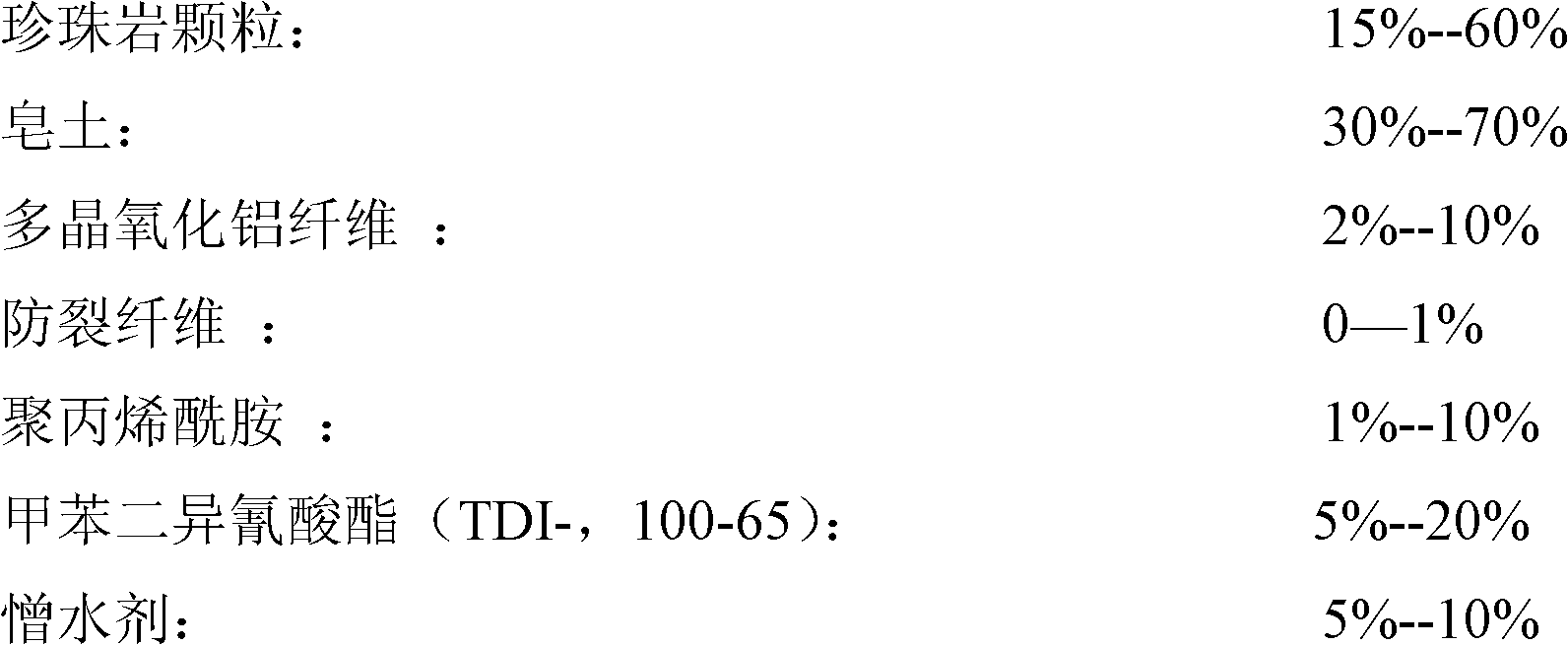

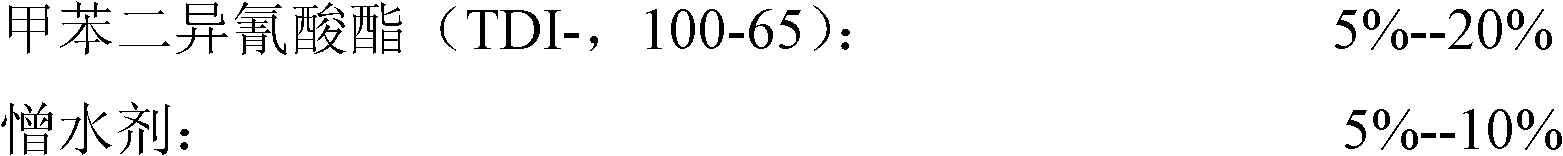

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: use density is 60kg / m 3 Perlite particles are used as raw materials to prepare insulation materials.

[0022] (1), adding 9% TDI by weight to an appropriate amount of water to form a mixed solution, putting 3.6% polycrystalline alumina fibers into the mixed solution of TDI and water, stirring and beating until the polycrystalline alumina fibers are completely dispersed;

[0023] (2) Add 45.6% bentonite and 0.5% anti-crack fiber to the mixed liquid prepared in step (1), and add an appropriate amount of water to continue stirring until the bentonite is fully mixed with the liquid to form a viscous slurry;

[0024] (3) Add an appropriate amount of water to polyacrylamide with a weight ratio of 2.3% to make it liquid, add it to the viscous slurry prepared in step (2), add 9% water repellent, and stir evenly to make a colloidal mother liquor ;

[0025] (4), the perlite particle that is 30% by weight is mixed into colloidal mother liquor, adds water and adjus...

Embodiment 2

[0028] Embodiment 2: use density is 60kg / m 3 Perlite particles are used as raw materials to prepare insulation materials.

[0029] (1), adding 9% TDI by weight into an appropriate amount of water, putting 3.6% polycrystalline alumina fibers into the mixture of TDI and water, stirring and beating until the polycrystalline alumina fibers are completely dispersed;

[0030] (2) Add 45.6% bentonite and 0.5% anti-crack fiber to the mixed liquid prepared in step (1), and add an appropriate amount of water to continue stirring until the bentonite is fully mixed with the liquid to form a viscous slurry;

[0031] (3), the polyacrylamide with a weight ratio of 2.3% is adjusted to a liquid state by adding an appropriate amount of water, and then added to the slurry in step (2), and then added with 9% water-repellent agent, stirred evenly, and made into a colloidal mother liquor;

[0032] (4), mixing the perlite particles with a weight ratio of 30% into the colloidal mother liquor, addin...

Embodiment 3

[0035] Embodiment 3: use density is 125kg / m 3 Preparation of insulation materials from perlite particles

[0036] (1), adding 7% TDI into an appropriate amount of water by weight, putting 2.9% polycrystalline alumina fibers into the mixture of TDI and water, stirring and beating until the polycrystalline alumina fibers are completely dispersed;

[0037] (2) Add 35.9% bentonite and 0.4% anti-crack fiber to the mixed liquid prepared in step (1), and add an appropriate amount of water to continue stirring until the bentonite is fully mixed with the liquid to form a viscosity slurry;

[0038] (3) Add an appropriate amount of water to polyacrylamide with a weight ratio of 1.8% to make it liquid, add it to the slurry in step (2), add 7% water repellent, and stir evenly to make a colloidal mother liquor;

[0039] (4), mixing the perlite particles with a weight ratio of 45% into the colloidal mother liquor, adding an appropriate amount of water to a suitable viscosity, stirring even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com