Heat-insulation and sound-insulation regenerated plastic tile and processing technology thereof

A technology of recycled plastic, thermal insulation and sound insulation, applied in roof insulation materials, other household appliances, roofs using tiles/slate tiles, etc. Achieve the effect of increasing thermal insulation, reducing cuts, and increasing thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

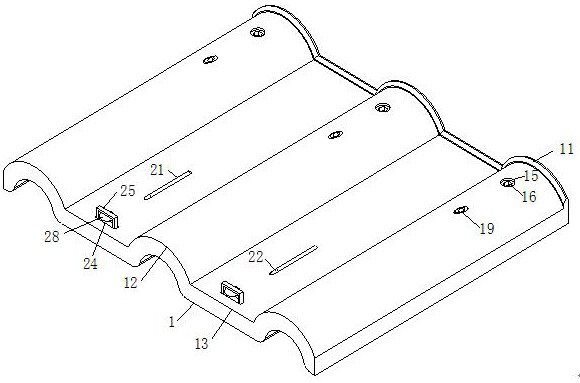

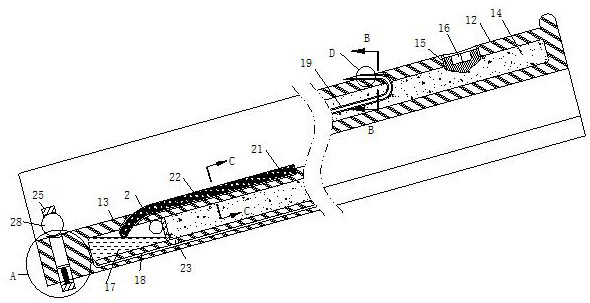

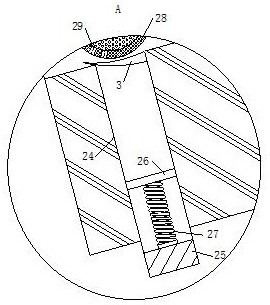

[0035] like Figure 1 to Figure 2 As shown, a heat-insulating and sound-insulating recycled plastic tile described in the embodiment of the present invention includes a main body 1, a flange 11 is provided on one side of the main body 1, and the main body 1 includes an arched portion 12 and a water guide portion 13. There is a cavity 14, the cavity 14 communicates with the outside world through the filling hole 15, and the filling hole 15 is internally threaded with a pin 16; the cavity 14 is filled with perlite particles; one end of the cavity 14 is divided by a partition Out of the water storage chamber 17, the bottom of the water storage chamber 17 is connected with a drainage hole 18, and the top of the water storage chamber 17 is provided with a water inlet hole, and a check valve is arranged in the water inlet hole; The side is provided with a nozzle 19, which communicates with the drain hole 18; the inner wall of the water storage chamber 17 is fixedly connected with a ...

Embodiment 2

[0044] like Figure 7 Shown, comparative example one, wherein another kind of implementation mode of the present invention is:

[0045] Described spout 19 is provided with spherical chamber 44 near outlet position, is connected with elastic membrane 45 in spherical chamber 44, and the side of elastic membrane 45 close to spout pipe 19 outlets is fixedly connected herringbone insert rod 46; Said elastic membrane 45 A group of micropores 47 are evenly distributed in the middle, and the side of the elastic film 45 close to the insertion rod 46 is fixedly connected with a billiard ball 48 through a pull cord; when the nozzle pipe 19 is filled with water, the elastic film 45 is squeezed, so that the elastic film 45 expands and the thickness becomes thinner Afterwards, the water flow is ejected through the expanded micropore 47, so that the elastic membrane 45 is deformed and drives the insertion rod 46 to clear the nozzle pipe 19, and then the water flow through the microhole 47 im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com