Method for applying pre-tightening force of tension spring to kinetic energy generation of electric automobile

A technology of electric vehicles and pre-tightening force, which is applied in the direction of generating mechanical power, vehicle components, machines/engines, etc., and can solve the problems of low power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

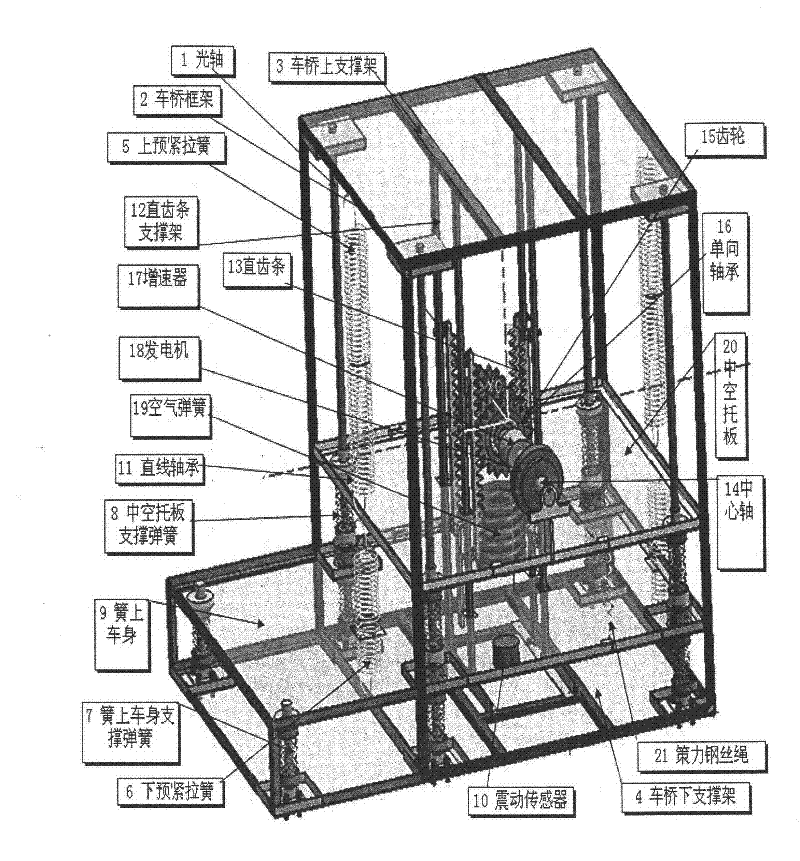

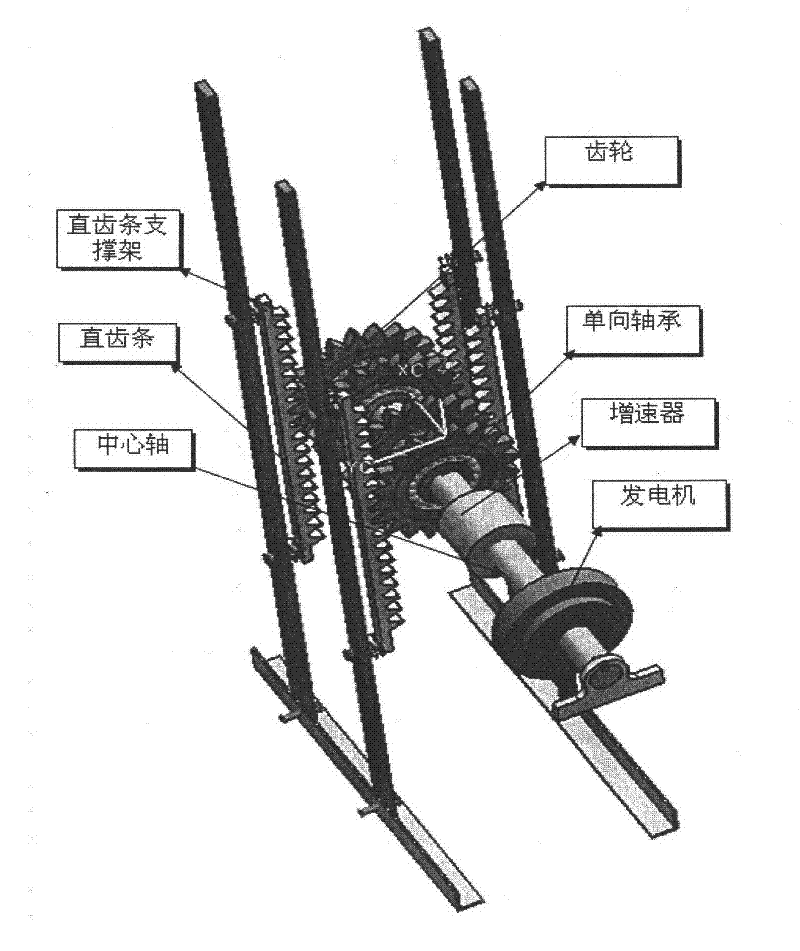

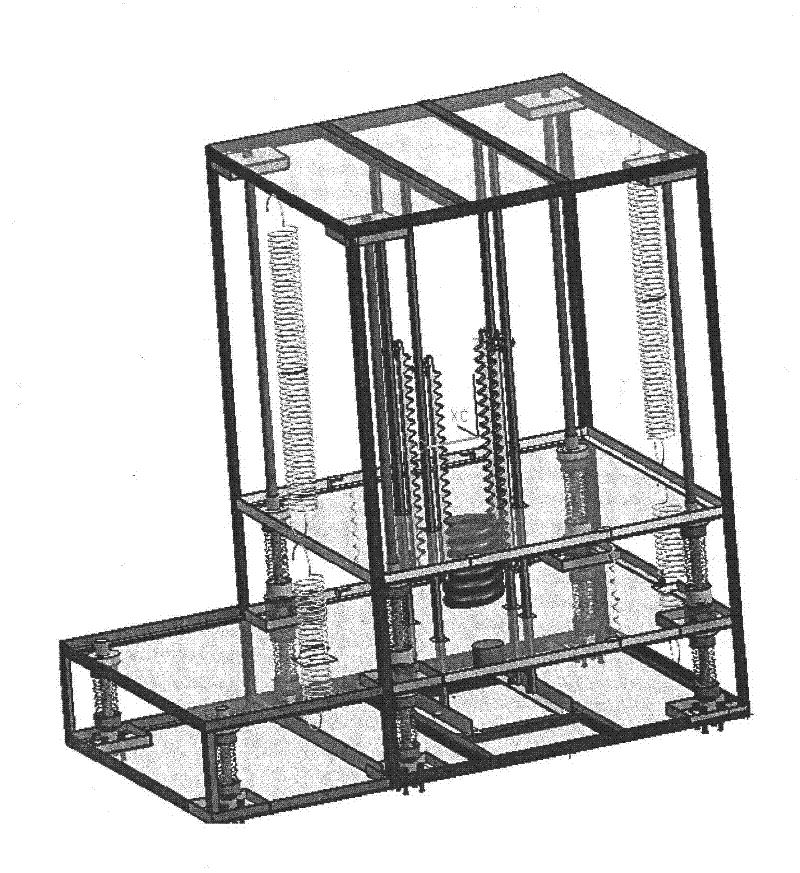

[0016] Supported by the four-corner bottom of the axle frame 2 that fixes the wheels, the optical axis 1 of the support spring 7 is vertically fixed, and the sprung body 9 of the electric vehicle is set on the vertical optical axis 1 of the axle through the linear bearings 11 provided at the four corners of the vehicle body floor. place and be pressed on the support spring 7, when the electric vehicle is running, the movement of the sprung vehicle body 9 is limited relative to the horizontal direction of the axle 2 and cannot be moved, and the vertical direction can freely vibrate up and down.

[0017] Similarly, with the bottom of the four corners of the sprung vehicle body 9 frame of the electric vehicle as the support, the optical axis 1 of the support spring 8 is vertically fixedly sleeved, and the hollow supporting plate 20 provided with linear bearings 11 at the four corners is pressed on the support spring 8, and the hollow supporting plate 20 can be fixedly placed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com