Phase object Z-scan-based pump-probe method

A pump detection, phase object technology, applied in the field of nonlinear photonics materials and nonlinear optical information processing, can solve the problems of sensitivity limitation, large measurement error, large error, etc., and achieve the effect of high measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

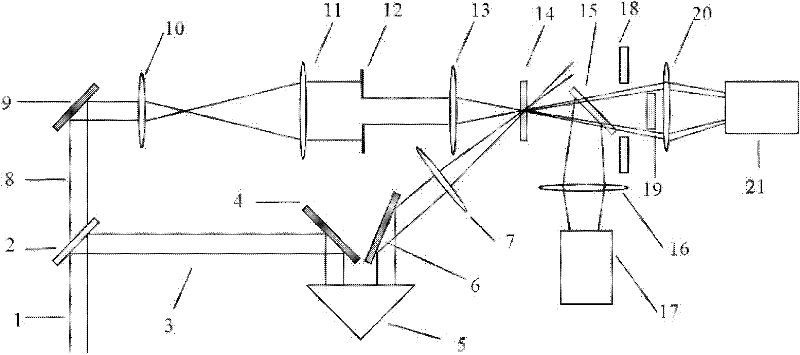

[0025] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

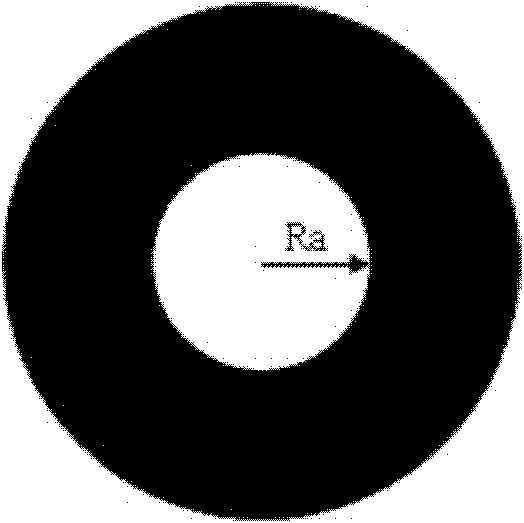

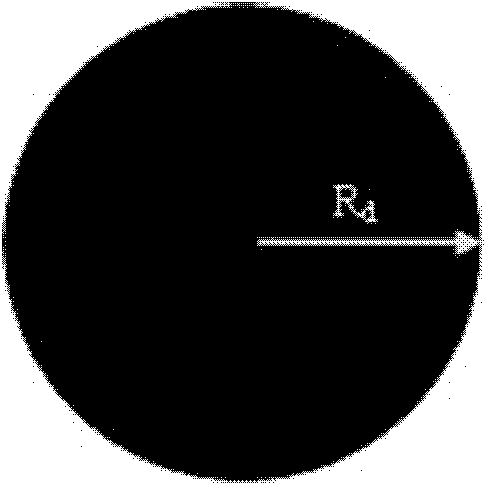

[0026] See attached image 3 As shown, a high-sensitivity measurement method for nonlinear parameters of optical functional materials is based on the detection optical path and the pumping optical path. The pumping optical path is mainly composed of two mirrors 4 and 6, a rectangular prism 5, and a convex lens 7. 5 can be translated back and forth to change the delay time of the pump light; the detection optical path is mainly composed of a reflector 9, a convex lens 10, a convex lens 11, a circular aperture 12, a convex lens 13, a beam splitter 15, a convex lens 16, and a circular diaphragm 18 ( The hole radius is R a ), circular baffle 19 (radius R d ), a convex lens 20, a first detector 17 and a second detector 21; the pump light path and the detection light path are simultaneously focused on the sample 14 to be tested.

[0027]A laser pulse 1 is split ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com