Control device and method of spark-ignition gasoline engine

A gasoline engine, spark ignition technology, applied in the direction of electric spark ignition controller, engine control, ignition controller, etc., can solve the problem that the pump loss cannot be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

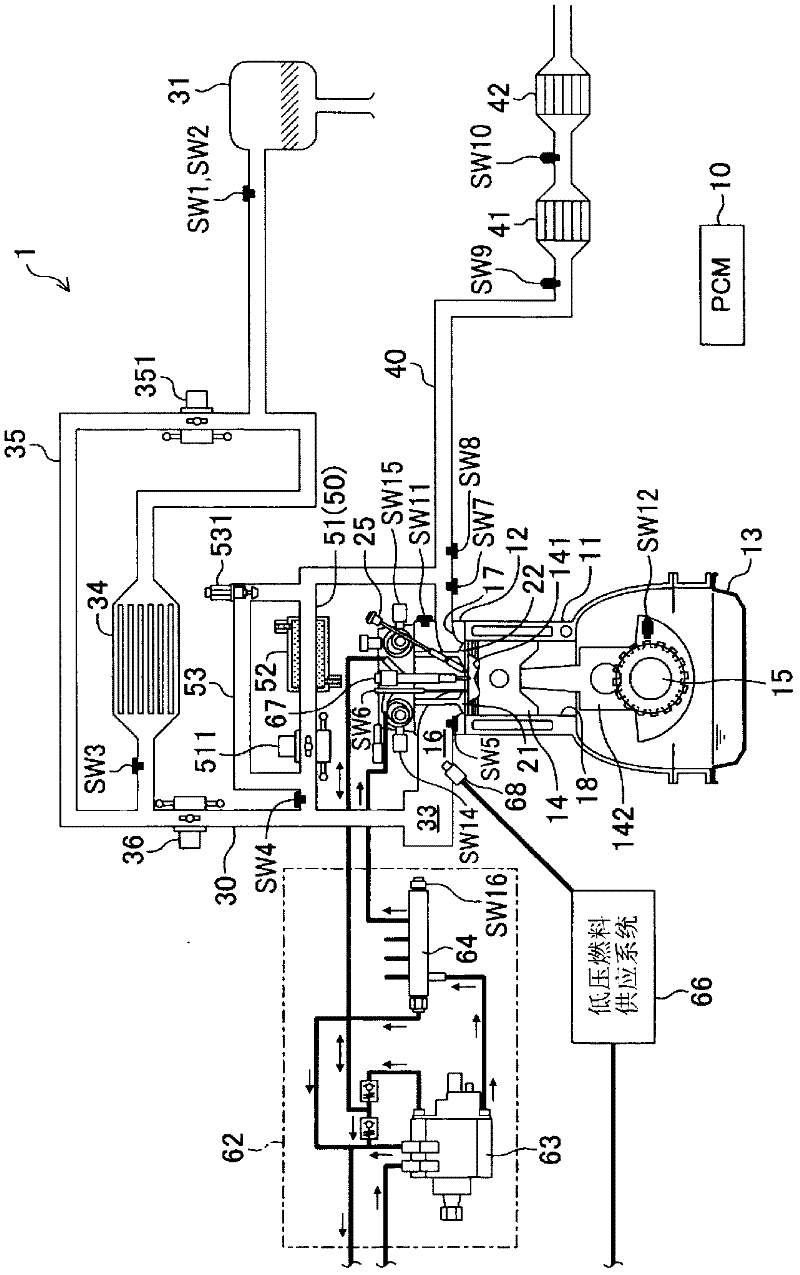

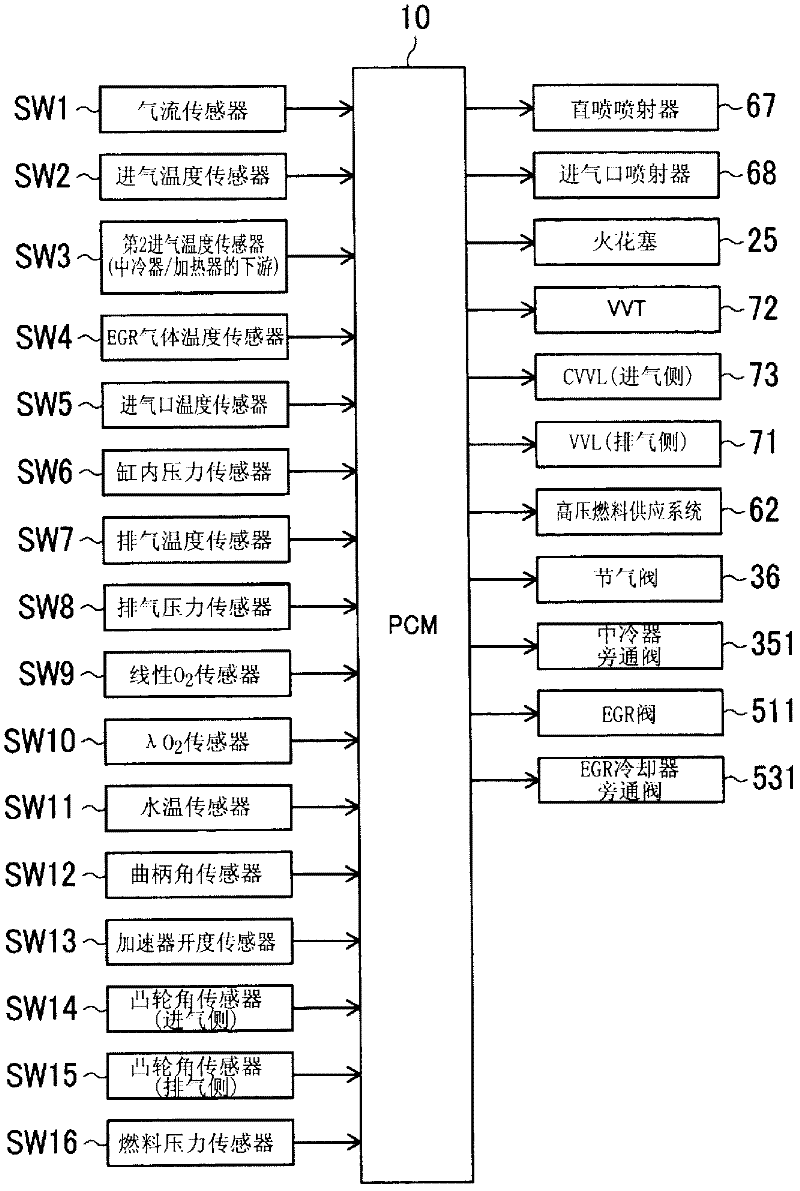

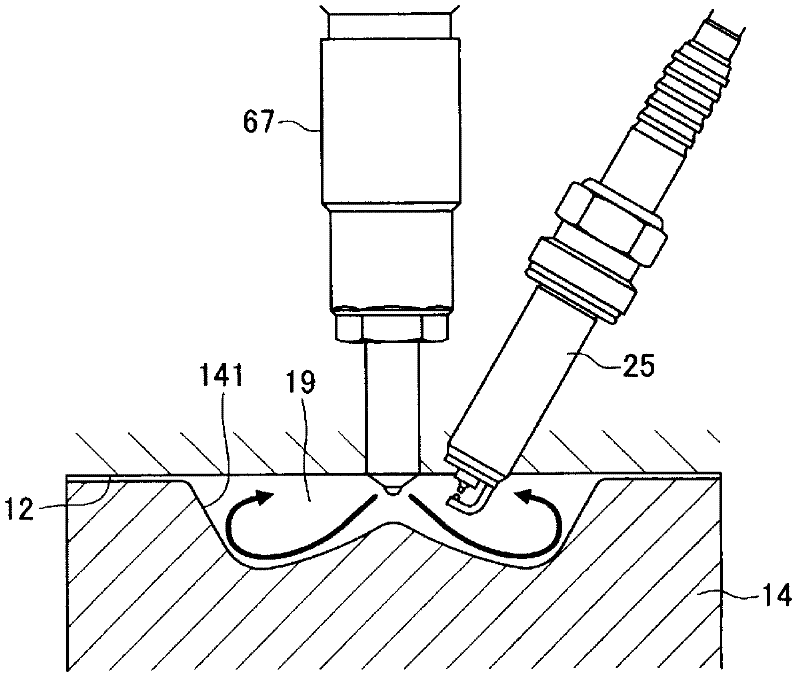

[0069] Hereinafter, an embodiment of a control device for a spark ignition type gasoline engine will be described based on the drawings. The description of the following specific embodiments is an example. figure 1 , 2The schematic structure of the engine (engine main body) 1 is shown. The engine 1 is a spark ignition type gasoline engine mounted on a vehicle and supplied with fuel containing at least gasoline. The engine 1 has a cylinder block 11 provided with a plurality of cylinders 18 (only one is shown), a cylinder head 12 provided on the cylinder block 11 , and an oil pan 13 provided below the cylinder block 11 and storing lubricating oil. A piston 14 connected to the crankshaft 15 via a connecting rod 142 is reciprocally inserted in each cylinder 18 . like image 3 The enlargement in , shows that a bowl-shaped cavity 141 is formed on the top surface of the piston 14 . The cavity 141 faces a direct injection injector 67 described later when the piston 14 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com