Plate-fin film type main cold liquid distributor for air separation

A technology of cold liquid and distributor, which is applied in the direction of refrigeration and liquefaction, liquefaction, solidification, etc., can solve problems such as difficult to obtain film cloth effect, main cold safety problem, excess liquid oxygen, etc., to improve the main cold safety problem, The effect of improving product quality and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below in conjunction with the accompanying drawings.

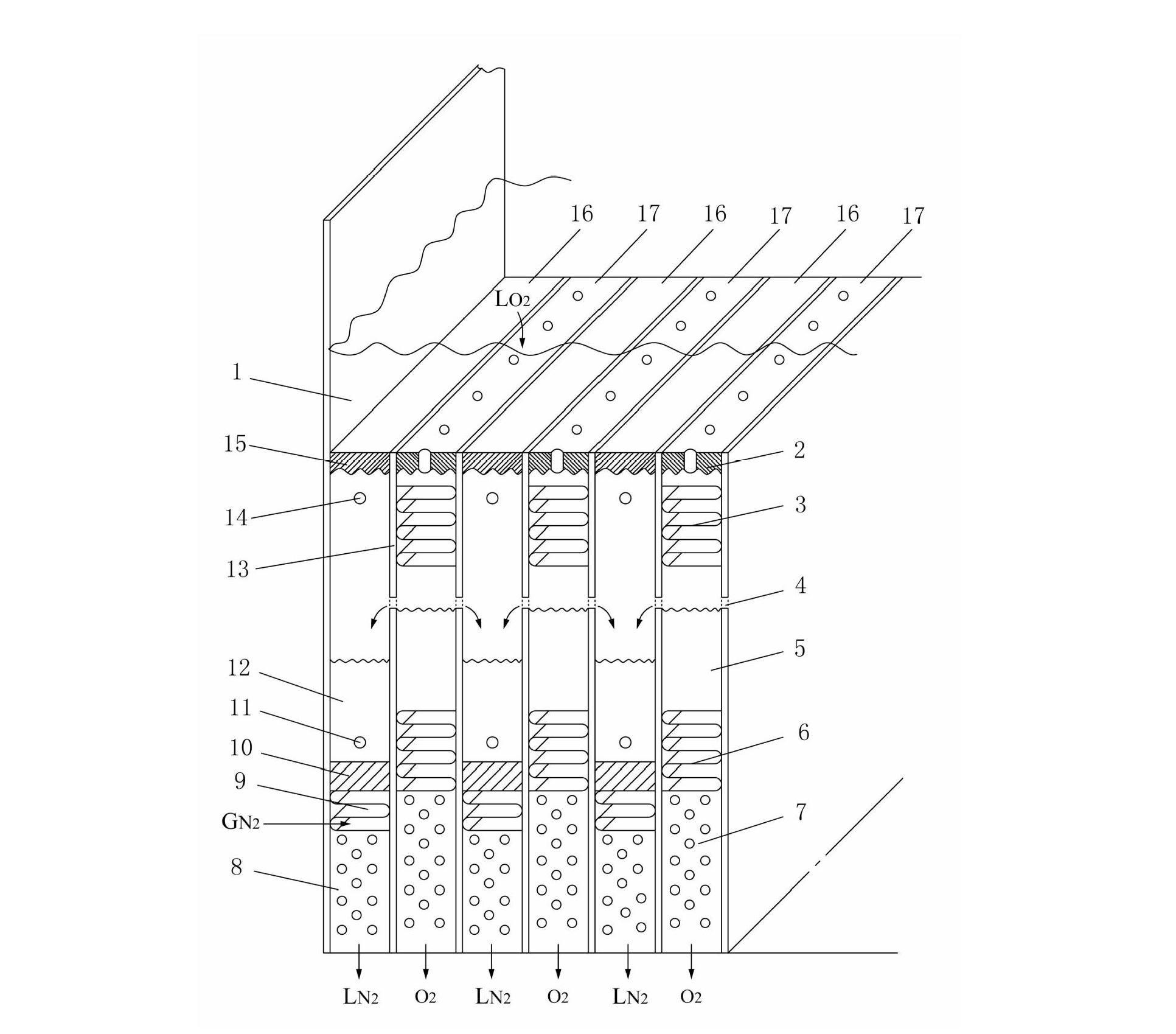

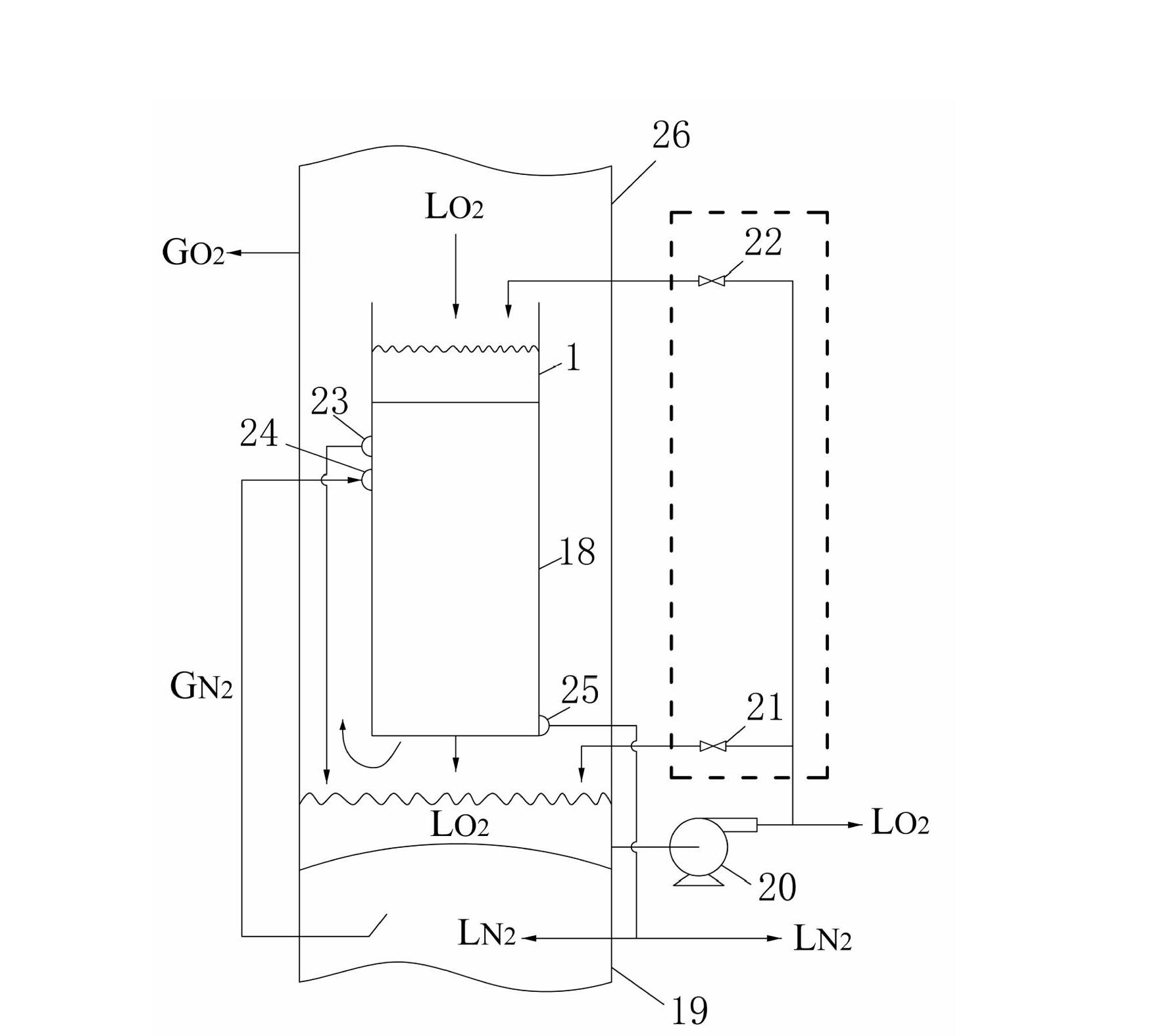

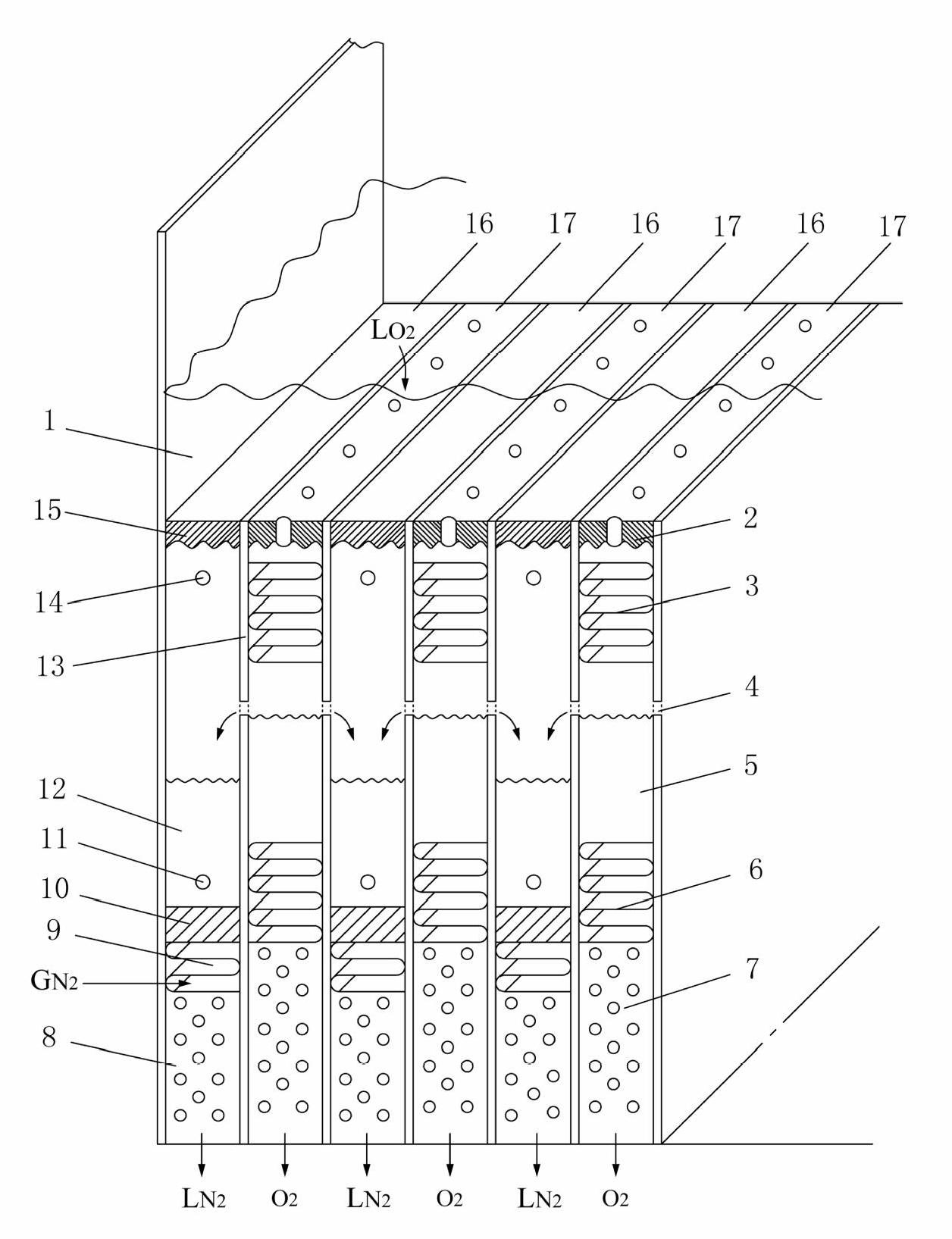

[0020] Such as figure 1 As shown, the present invention relates to an air separation plate-fin type film-type main cooling liquid distributor, comprising at least one first vertical channel 16 and at least one second vertical channel 17 arranged alternately and sequentially, the first vertical channel Channel 16 and the second vertical channel 17 are separated by vertical partitions 13 on both sides. The first vertical channel 16 includes a seal 15 that is arranged on its top and is connected to the liquid oxygen tank 1, and is arranged below the seal 15. Oxygen storage tanks 12 with preset gaps are provided with liquid outlet holes 11 on the lower side of the oxygen storage tank 12, the bottom of the oxygen storage tank 12 is connected with the seal 10, the seal 10 is connected with the deflector 9, and the deflector 9. The bottom communicates with the condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com