Fully-automatic semi-spiral energy-saving lamp powder-brushing machine and powder-brushing process thereof

An energy-saving lamp, fully automatic technology, applied in the direction of tube/light screen manufacturing, application of luminous paint, etc., can solve the problems of increased production cost, quality defects, low production efficiency, etc., to improve product qualification rate, simple and reasonable structure, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention will be further described:

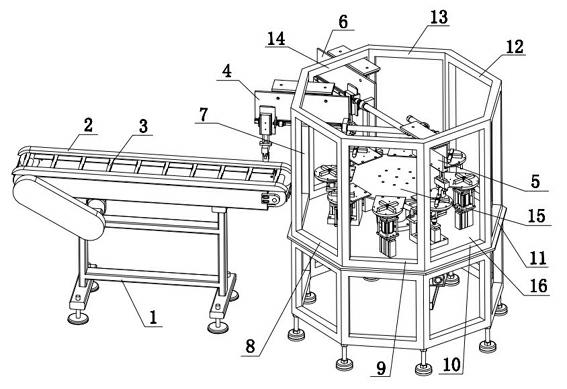

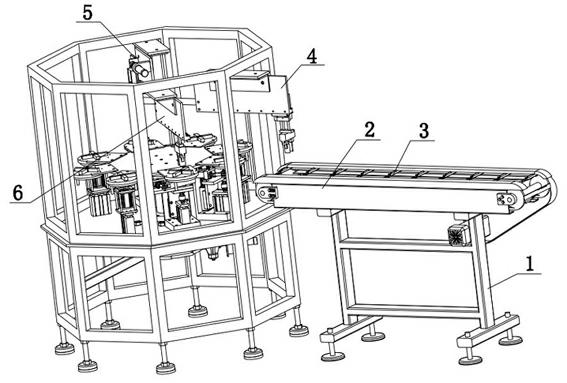

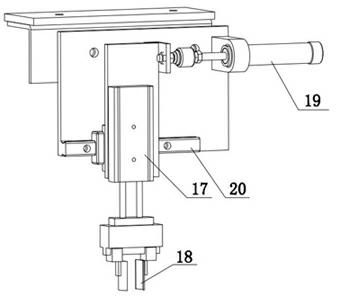

[0038] Fully automatic semi-screw energy-saving lamp powder brushing machine, including a conveying mechanism and a rotating powder brushing mechanism that are connected together. The conveying mechanism is composed of a conveying frame, a motor, a reducer, a transmission chain and a workpiece positioning device. The workpiece positioning devices are all set on the conveyor frame, the motor and the reducer are integrated, the reducer drives the transmission chain to rotate, the workpiece positioning device is set on the guide rod between the transmission chains on both sides, and moves together with the transmission chain. , the two pins of the semi-screw lamp tube are located on both sides of the workpiece positioning device to prepare for the subsequent powder painting; the rotating powder brushing mechanism includes eight-sided powder brushing frame, station plate, suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com