Complementary metal oxide semiconductor (CMOS) image sensor and manufacturing method thereof

A technology of an image sensor and a manufacturing method, applied in the semiconductor field, can solve the problems of high power consumption and difficult integration of a CCD image sensor, and achieve the effects of improving image quality and preventing oxidation and enhancing diffusion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

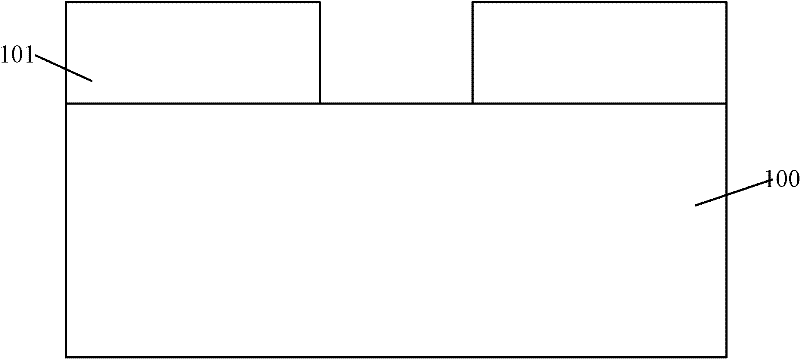

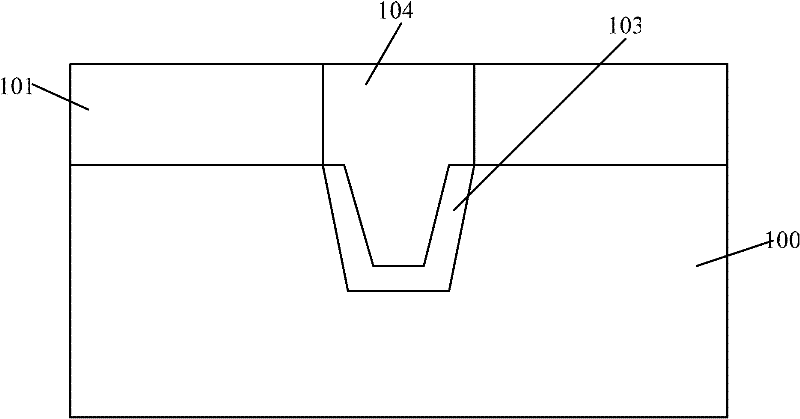

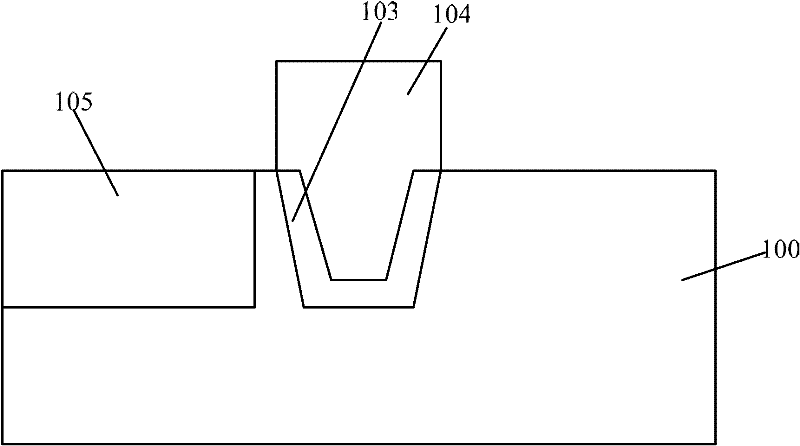

[0034] The imaging quality of existing CMOS image sensors is not high. After research by the inventors, it is found that one of the main reasons for the poor imaging quality of the CMOS image sensor is that the dark current of the CMOS image sensor is relatively large. Specifically, combined with image 3 One of the main causes of dark current is due to the dangling bonds at the interface between the liner layer 103 of the shallow trench isolation structure and the semiconductor substrate 100, and the dangling bonds will be between the liner layer 103 and The interface between the semiconductor substrates 100 forms an interface state defect, so that a large amount of electrons are easily formed on the interface between the pad layer 103 and the semiconductor substrate 100 due to heat generation (the reason for the heat generation is due to the fabrication of semiconductor devices. Various heating processes required in the process, such as oxidation process, annealing process)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com