System for measuring granularity of pulverized coal of blast furnace coal powder injection middle-speed milling system

A technology of pulverized coal particle size and blast furnace coal injection, which is applied in the field of metallurgy, can solve problems such as the inability to adjust the pulverizing production process in real time, the long time of manual laboratory measurement, and the difficulty of continuous on-line measurement, etc. It achieves convenient application and maintenance, and realizes self-learning, The effect of strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

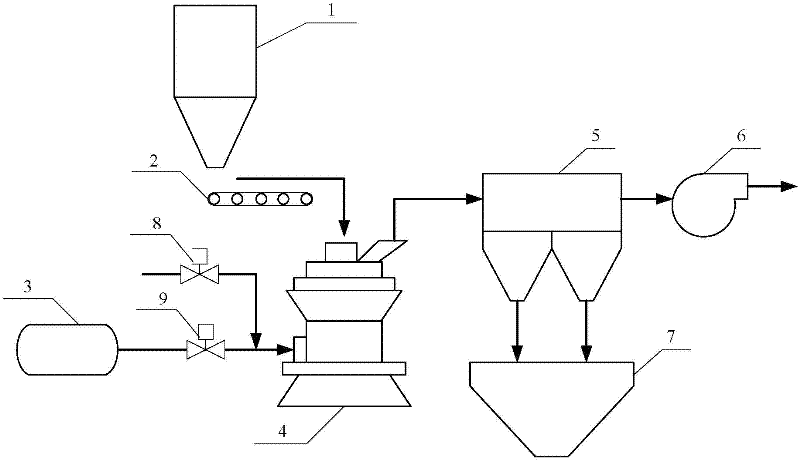

[0019] Such as figure 1 As shown, the blast furnace coal injection pulverization system is an important key to the blast furnace coal injection system, and its important process index coal powder particle size is related to the continuity of the subsequent process pulverized coal injection and the stability of the blast furnace production. Its task is to send the raw coal from the raw coal bunker 1 to the medium-speed coal mill 4 through the belt coal feeder 2 and grind it into coal powder. The dry gas generator 3 generates hot air, and the cold air valve 8 and hot air valve 9 Adjust the temperature of the dry gas, and then transport the pulverized coal to the bag-type powder coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com