Binder dent gauge protection underreamer with elastic floating sleeve

A floating sleeve and reamer technology, applied in casing, construction, earth-moving drilling, etc., can solve problems such as increased heat generation, failure to work properly, wheel drop accidents, etc., to reduce friction coefficient and prolong service life. , the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

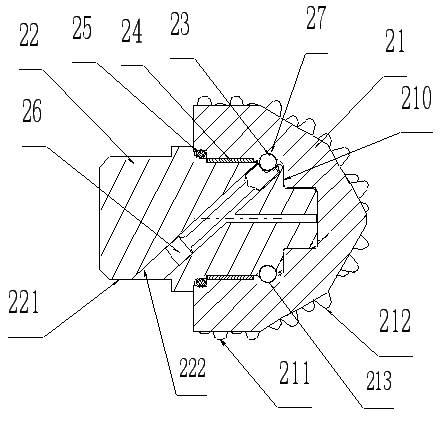

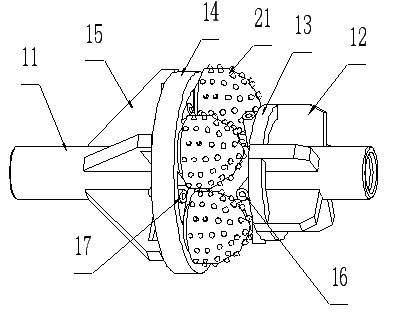

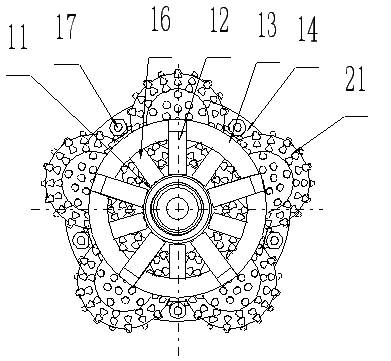

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a side tooth gauge diameter reamer with an elastic floating sleeve includes a reamer body and a cone assembly composed of a cone 21 and a cone seat 22. The reamer body is mainly composed of Both ends are provided with drill pipe joint thread 110 body mandrel 11, ring plate 13, main board 14, front guide plate 12, rear guide plate 15, radial water pipe 16, inclined water pipe 17, the front guide plate, ring plate , the main board, and the rear guide plate are fixedly connected to the mandrel of the body in sequence from front to back, and no less than three cone seat mounting holes 140 are evenly distributed on the upper circumference of the main board, and the radial water pipes are placed on the front guide plate The rear and radially penetrate the mandrel of the body. The inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com