Porous linear control hydraulic fracturing method

A hydraulic fracturing and hole line technology, applied in the field of hydraulic fracturing, can solve the problems of difficult to control the direction of crack propagation in the hole, difficult to ensure safety, high water pressure, etc. The effect of coal and gas outburst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

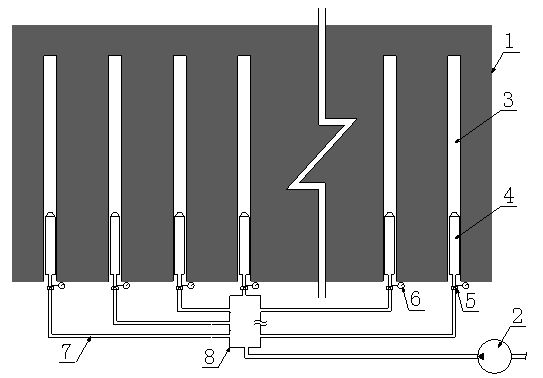

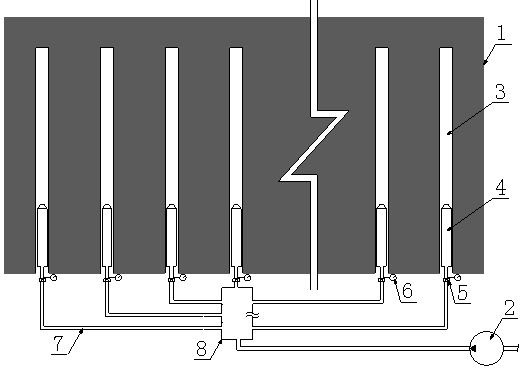

[0016] Embodiment one: if figure 1 As shown, the average thickness of the coal seam in a mine is 1.5m, the average dip angle is 6°, and the hardness of the coal seam is f=2; the immediate roof is light gray medium-grained sandstone with an average thickness of 2.28m; the old roof is gray-black sandy mudstone with an average thickness of 5.33m . Adopt roof directional cutting seam to keep entry along the gob. On the 30m ahead of the working face of the wind tunnel, eight hydraulic fracturing holes 3 arranged in a plane and linear arrangement are constructed one by one by the vertical roof of the side road side of the working face. The diameter of the holes is 32mm, the hole depth is 5m, and the hole spacing is 0.5m. The working face advances in the direction of construction. After the construction of the 8 boreholes, the 8 boreholes 3 are sealed one by one with the hole sealer 4, and the water injection pipelines 7 are connected respectively, and the water injection pipelines...

Embodiment 2

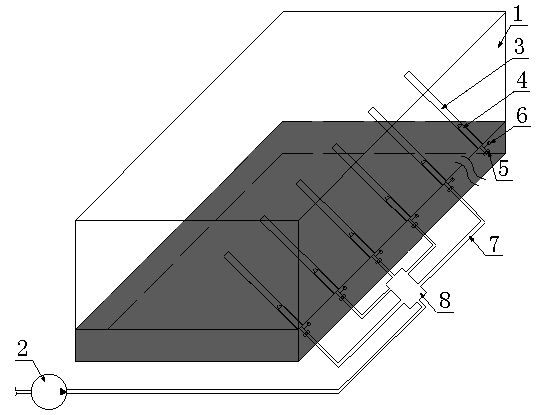

[0017] Embodiment two: if figure 2 As shown, the average thickness of a coal seam in a certain mine is 2.64m, the average dip angle is 2°, and the hardness of the coal seam is f=2.7-3.7; , average thickness 4.24m, hardness f=6.3. The directional hydraulic fracturing technology is used to control the hard roof, and five hydraulic fracturing drilling holes 3 are linearly arranged at an elevation angle of 45° in front of the oblique working face of the coal wall. The drilling diameter is 42 mm, the hole depth is 9.2 m, and the drilling distance is 1m, followed by construction along the direction of the working face. After the construction of the 5 boreholes, use the hole sealer 4 to seal the 5 boreholes 3 one by one, and connect the water injection pipeline 7 respectively, and the water injection pipeline 7 is connected to each borehole 3. Water injection valves 5 are provided at the openings With the pressure gauge 6, five boreholes 3 are connected to the equal flow divider 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com