Non-contact three-dimensional measurement device and method for particle movement of fluidized bed

A non-contact, particle motion technology, applied in the analysis of materials, instruments, etc., can solve the problems of particle motion in gas-solid fluidized beds, unsatisfactory accuracy, and difficulty in 3D measurement, and achieves the difference between imaging speed and particle motion rate. Matching, real-time measurement, and environmental safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

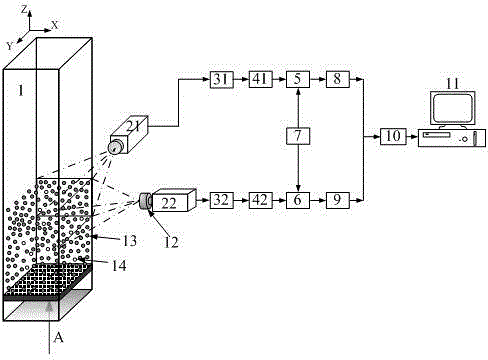

[0020] Refer below figure 1 Specifically illustrate the technical route of the present invention and the realization of the goal:

[0021] First select a small amount of bed material 13, use a mass fraction of 20% Na 131 The I aqueous solution was soaked for 4 hours, and after taking it out, it was sealed and dried at 60 degrees Celsius for 3 hours to make tracer particles 14. The carrying amount of radioactive compounds in the tracer particles 14 was between 0.5-1 micrograms, and the radioactivity was greater than 1MBq / L (megabytes). Beck per liter). Spread a small amount of bed material 13 evenly in the fluidized bed 1, then evenly sprinkle the prepared tracer particles 14 on the laid bed material 13, and finally cover a large amount of bed material 13 on the fluidized bed according to the required amount of operation. Tracking particles 14, spread in the fluidized bed 1. The fluidized bed 1 is made of non-metallic materials with weak gamma-ray absorption capacity, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com