Copper strip surface defect detection system based on multi-feature fuzzy recognition

A defect detection and fuzzy recognition technology, applied in character and pattern recognition, optical test defect/defect, instrument, etc., can solve the problems of not considering the defect judgment link, not storing the copper strip surface quality image module, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

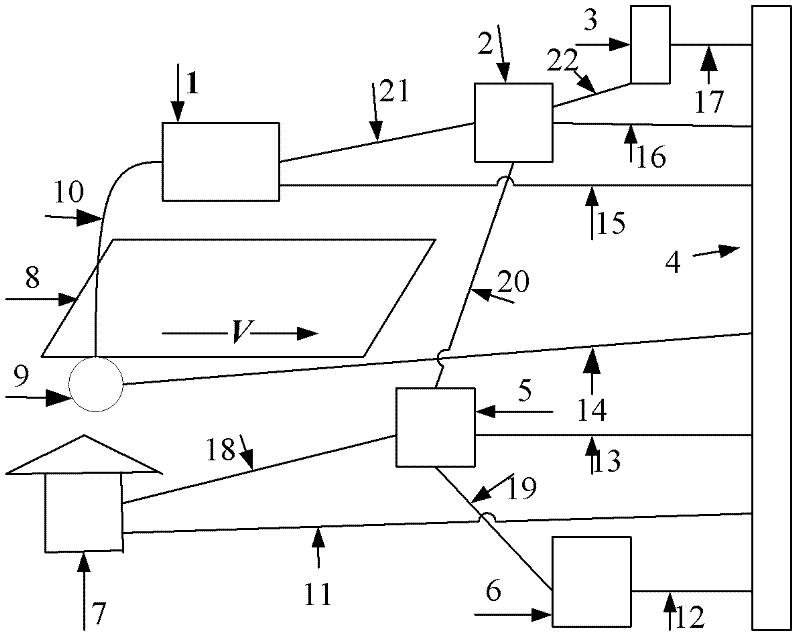

[0061] The present invention will be further described below in conjunction with the accompanying drawings.

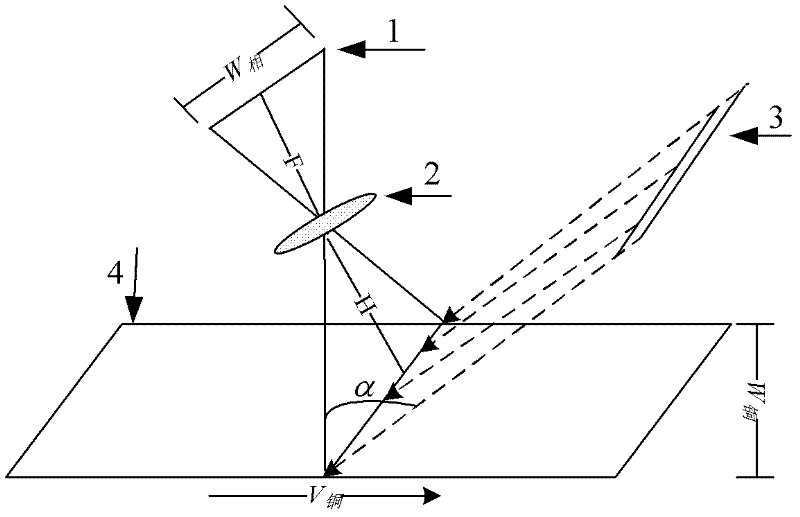

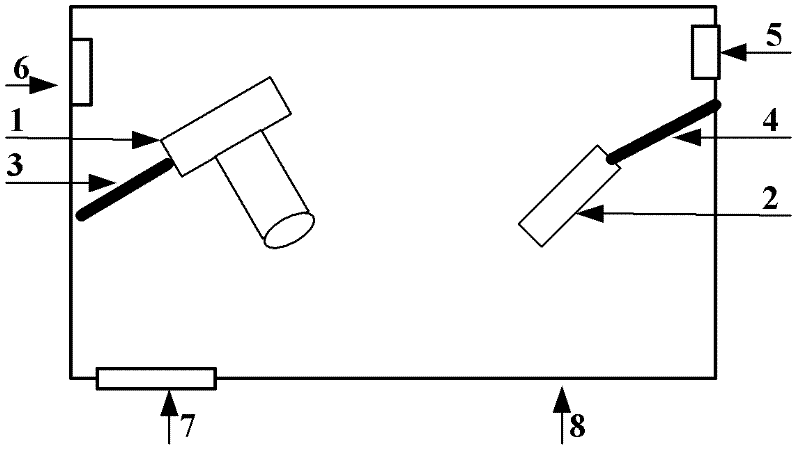

[0062] refer to Figure 1 to Figure 6 , a copper strip surface defect detection system based on multi-feature fuzzy recognition, said system includes an encoder module, used to obtain the speed information of copper strip operation, and generate a frequency signal; the image acquisition module 1 mainly includes an illumination unit and an image acquisition unit , wherein the lighting unit is a controllable linear array LED light source, and the image acquisition unit is a color linear array CCD industrial camera. This module mainly completes the acquisition of copper strip surface information; The color image of the surface of the copper strip is grayscaled and processed into a grayscale image. The second step is to use the median filter algorithm to remove noise. The third step is to perform a pre-judgment algorithm on the image to determine whether the image contains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com