Device for measuring current density distribution of arc

A density distribution and arc current technology, applied in current density measurement and other directions, can solve the problems of unintuitive measurement results and insufficient measurement accuracy, and achieve the effect of simple measurement operation process, simple data processing, and simple installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

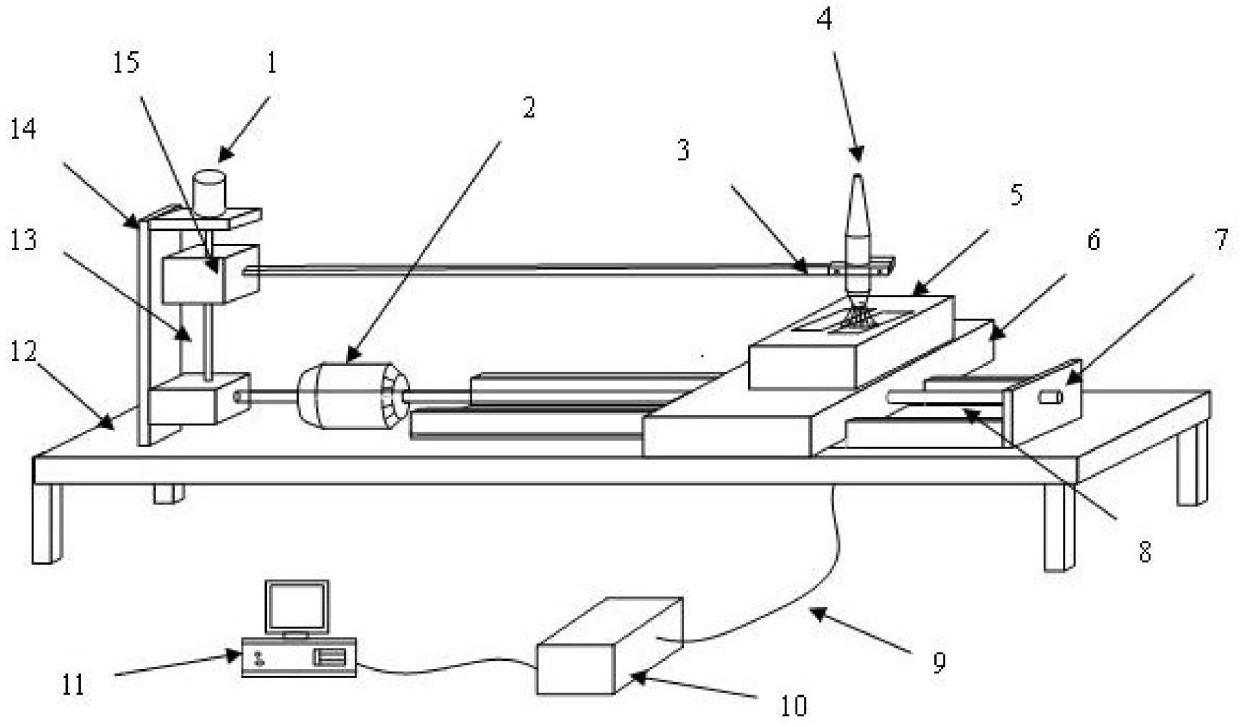

[0041] A device for measuring arc current density distribution according to the present invention is assembled according to the following steps:

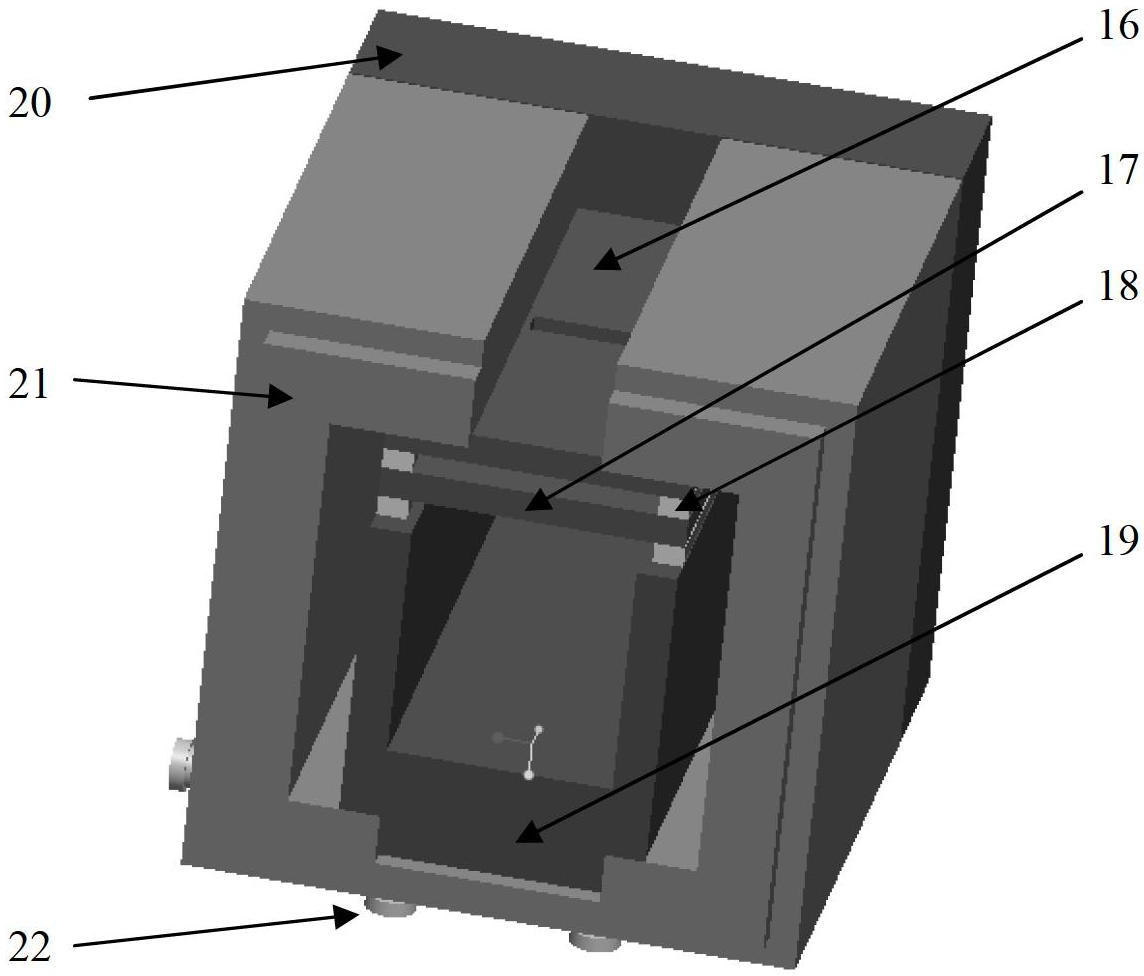

[0042] Step 1: If figure 2 As shown, the assembly of the current receiving sensing device 5: it includes a casing 21, the casing 21 is through front and back, and a wide slit with a width smaller than the upper receiving copper plate 16 is set in the middle of the top; the concave support block 19 is built in the casing, and the The concave support block 19 is provided with an upper receiving copper plate 16, a lower receiving copper plate 17, and an insulating layer 18 placed between the upper receiving copper plate 16 and the lower receiving copper plate 17; adjusting screws 22 are set at the four corners of the bottom of the shell, and the height of the adjusting screw 22 is adjusted. , so that the concave support block 19 and the shell 21 clamp and position the upper receiving copper plate 16, the middle insulating layer 18, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com