Stainless steel corrugated oil storage tank and manufacturing process thereof

A manufacturing process and oil storage tank technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the unfavorable transportation and installation of transformer oil storage tanks, low space utilization of oil storage tanks, and large volume of transformer oil storage tanks And other problems, to achieve the effect of beautiful appearance, high utilization rate, convenient use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

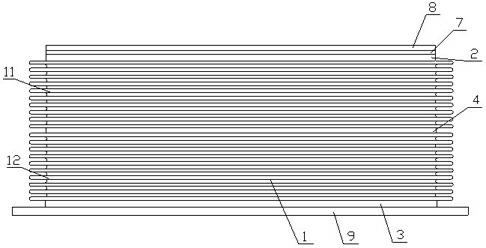

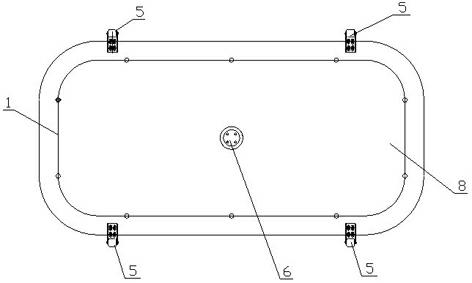

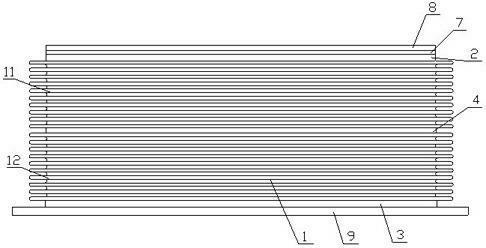

[0033] The manufacturing process of the stainless steel corrugated oil storage tank comprises the following steps:

[0034] (1) Cutting, cutting the stainless steel plate according to the design size;

[0035] (2) Welding, using an automatic longitudinal seam welding machine to weld the blanked stainless steel plate into a circular tube. This step requires smooth and smooth welds;

[0036] (3) Expanding the wave, the circular tube is made into a bellows by an automatic hydraulic expanding machine. This step requires the inside of the bellows to be clean and free of garbage;

[0037] (4) Shaping and cleaning, use a shaping machine to make the wave distance and wave height of the bellows uniform, and clean the oil and dust inside the wave crest of the bellows. This step requires no wave height and oblique bending;

[0038] (5) Pulling, pulling the bellows into a rectangular structure, knocking the two ends of the bellows into a flat connection surface, and making the connection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com