Automatic press fitting equipment for automobile brake disc bearing

A technology of automobile braking and press-fitting, which is applied in metal processing equipment, manufacturing tools, metal processing, etc., can solve problems such as oil leakage and pollution of workstations, and achieve the effects of improving production efficiency, reducing labor intensity, and occupying a small space for equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

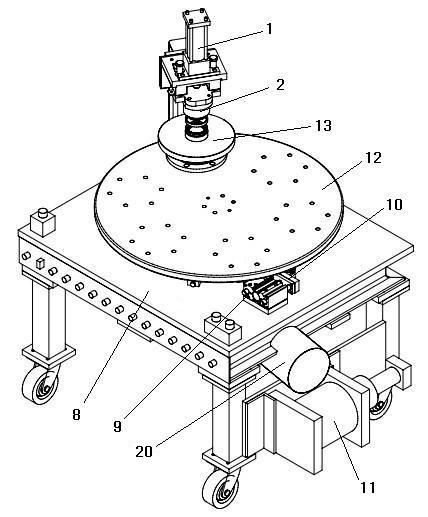

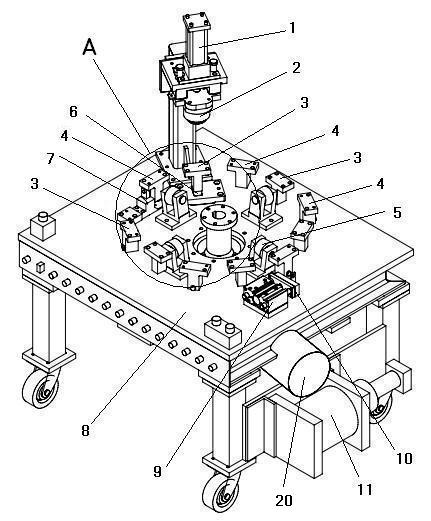

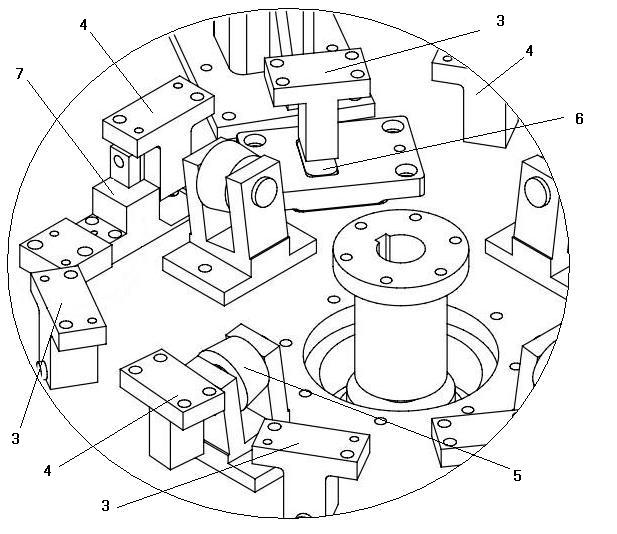

[0016] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 .

[0017] An automatic press-fitting device for automobile brake disc bearings, comprising a press-fit mechanism, a rotary positioning mechanism, a rotary table 8, and an automatic control system, the press-fit mechanism and the rotary positioning mechanism are installed on the rotary table 8 , the press-fitting mechanism is located above the rotary positioning mechanism, and the press-fitting mechanism includes a press-fitting cylinder 1, a press-fitting head 2, an air-oil booster power system 11, and the air-oil booster power system 11 is connected to the The press-fitting cylinder 1 is connected to provide a power source, the press-fitting head 2 is installed on the piston rod of the press-fitting cylinder 1, and the press-fitting mechanism and the rotating positioning mechanism are controlled by the automatic control system.

[0018] The rotary positioning mechanism includes a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com