Water surface floater recovery ship

A technology for floating objects and hulls on the water surface, which is used in the cleaning of open water surfaces, water conservancy projects, special-purpose ships, etc. It can solve the problems of limited storage tank capacity, troublesome operation, and complex structure, so as to improve the efficiency of unloading operations and reduce operation time. , the effect of expanding the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

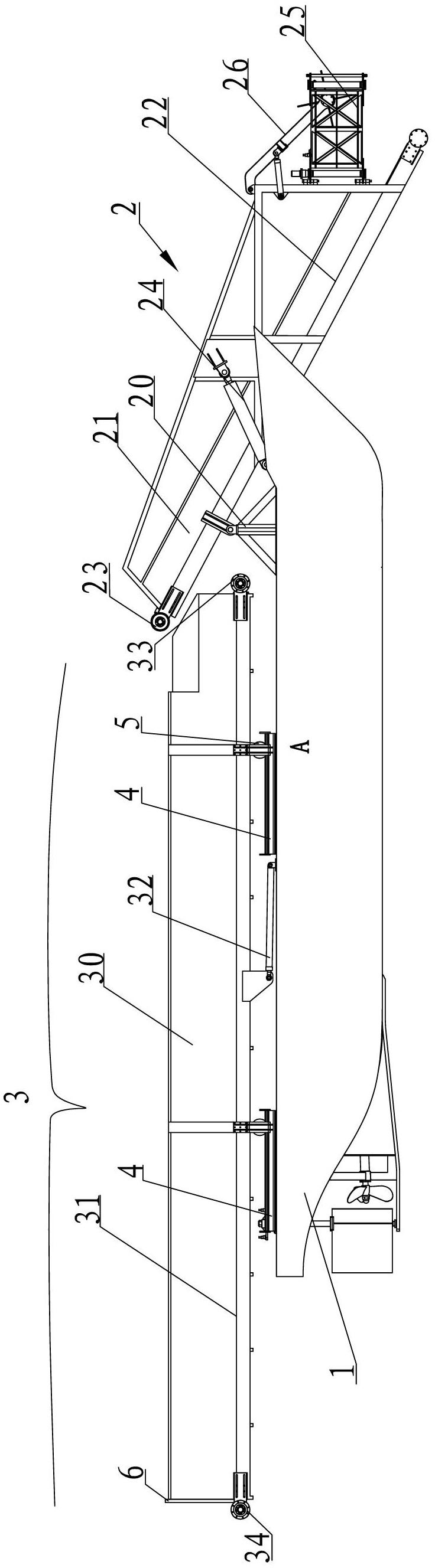

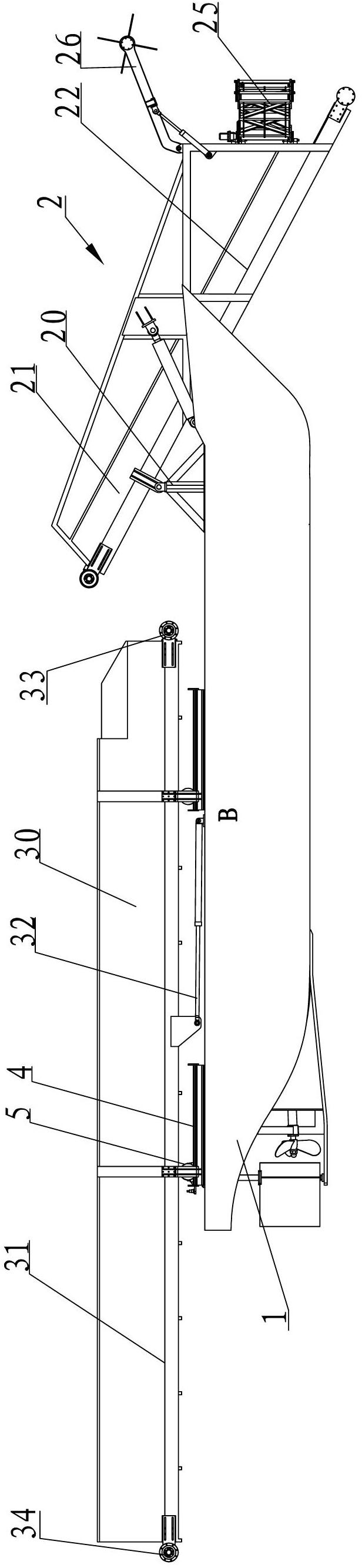

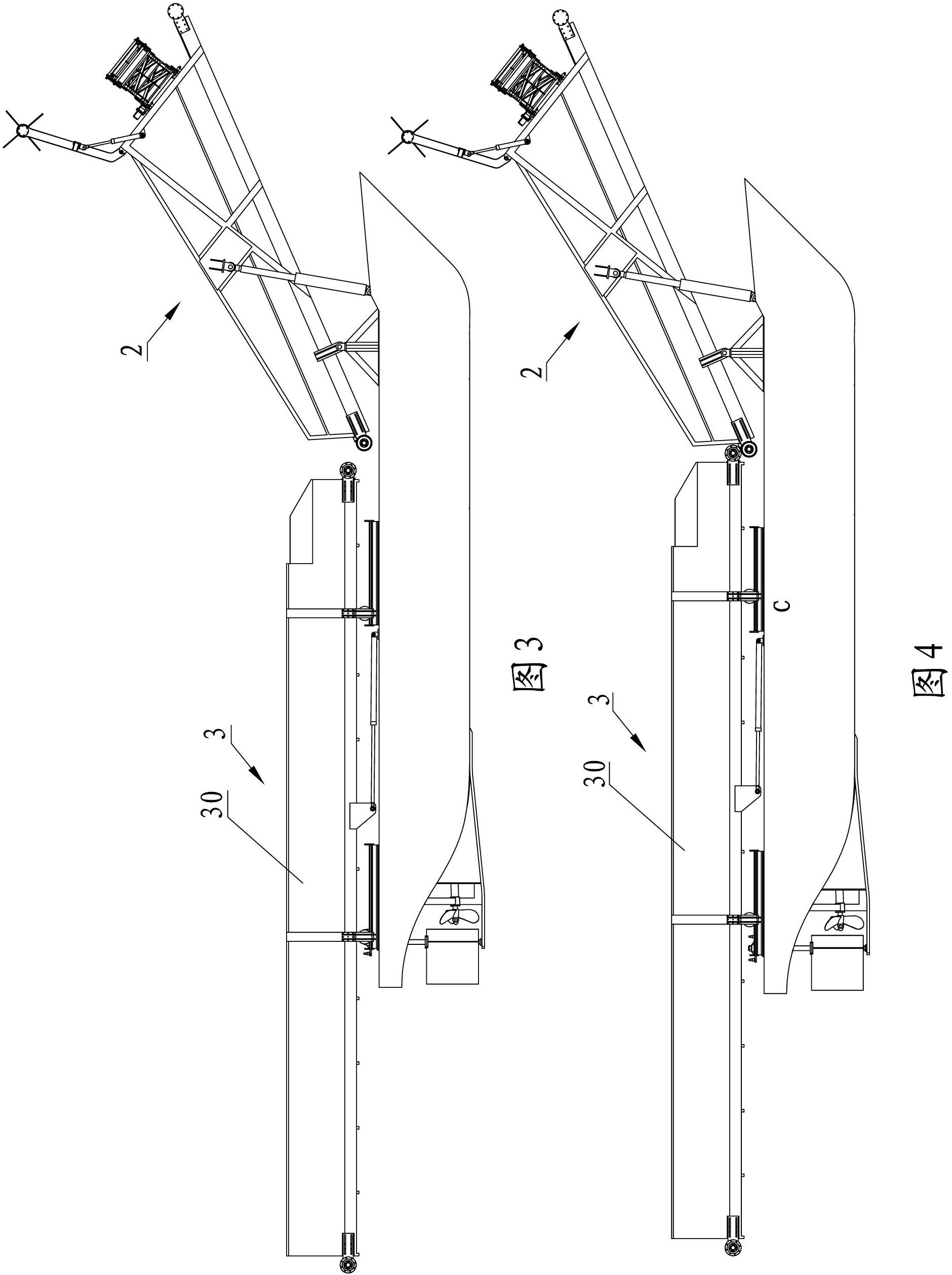

[0021] According to the water surface floating object collection ship of the present invention is a conveyer belt type collection ship, its basic structure includes the hull that is provided with cab, running gear, power mechanism and harvesting system, and wherein hull, running gear and power mechanism all can refer to Conventional technical implementation, which will not be described in detail below. The present invention mainly relates to the improvement of the harvesting system: the harvesting system of the present invention no longer has a conveying cabin, but only consists of a harvesting device and a storage device to realize front-end harvesting and front-end unloading. Thereby, the operating time of the hull U-turn required for the unloading of the original rear-end conveying cabin is effectively reduced, and the unloading operation efficiency is improved.

[0022] The harvesting system according to the present invention will be described in further detail below i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com