Preparation device and preparation method of sodium pyrosulfite and anhydrous sodium sulphite

A technology of anhydrous sodium sulfite and sodium pyrosulfite, which is applied in the field of boiling furnace preparation technology, can solve problems such as rising production costs, rising prices, and fierce market competition, and achieve the effects of low production costs and improved utilization rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

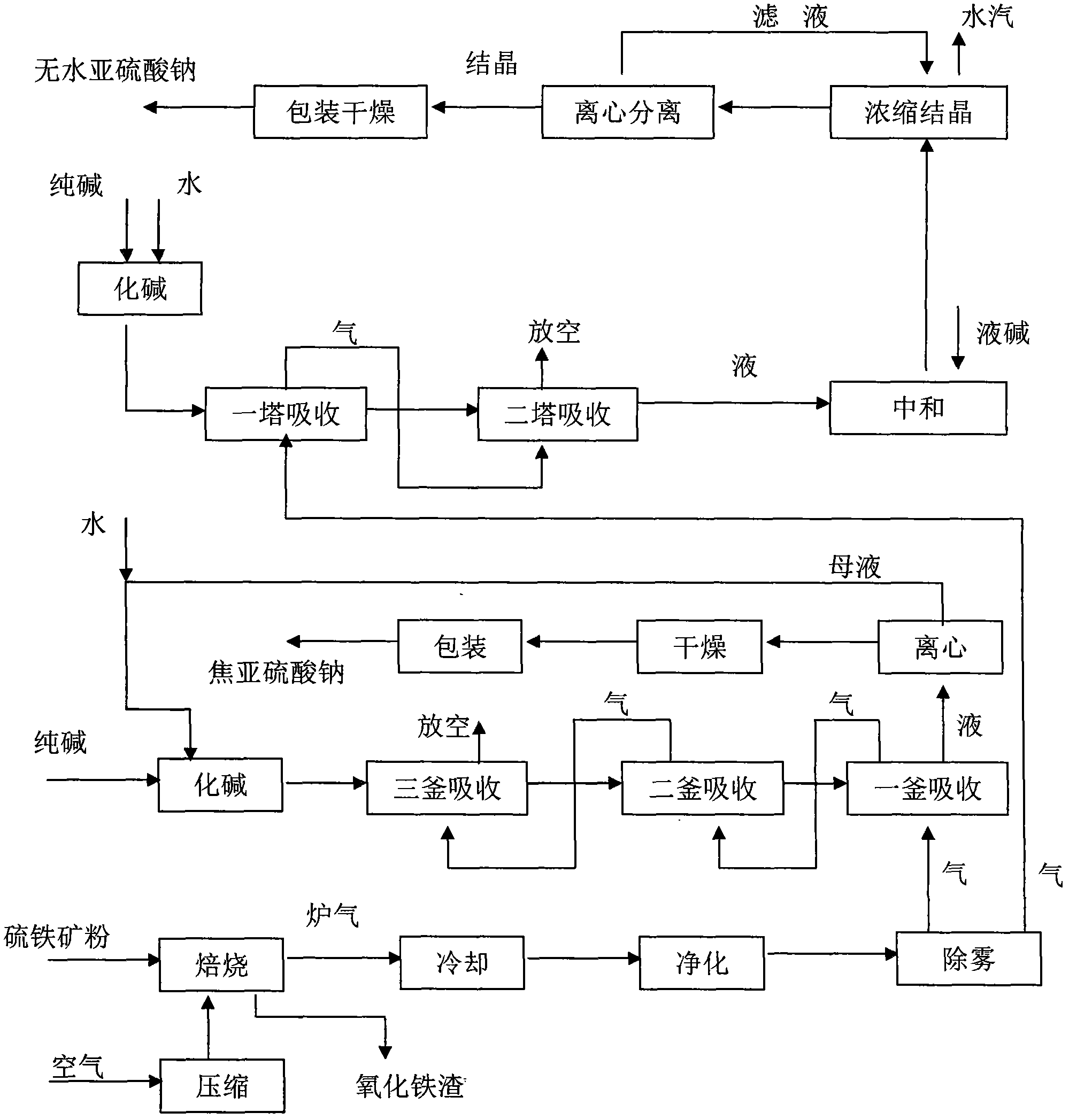

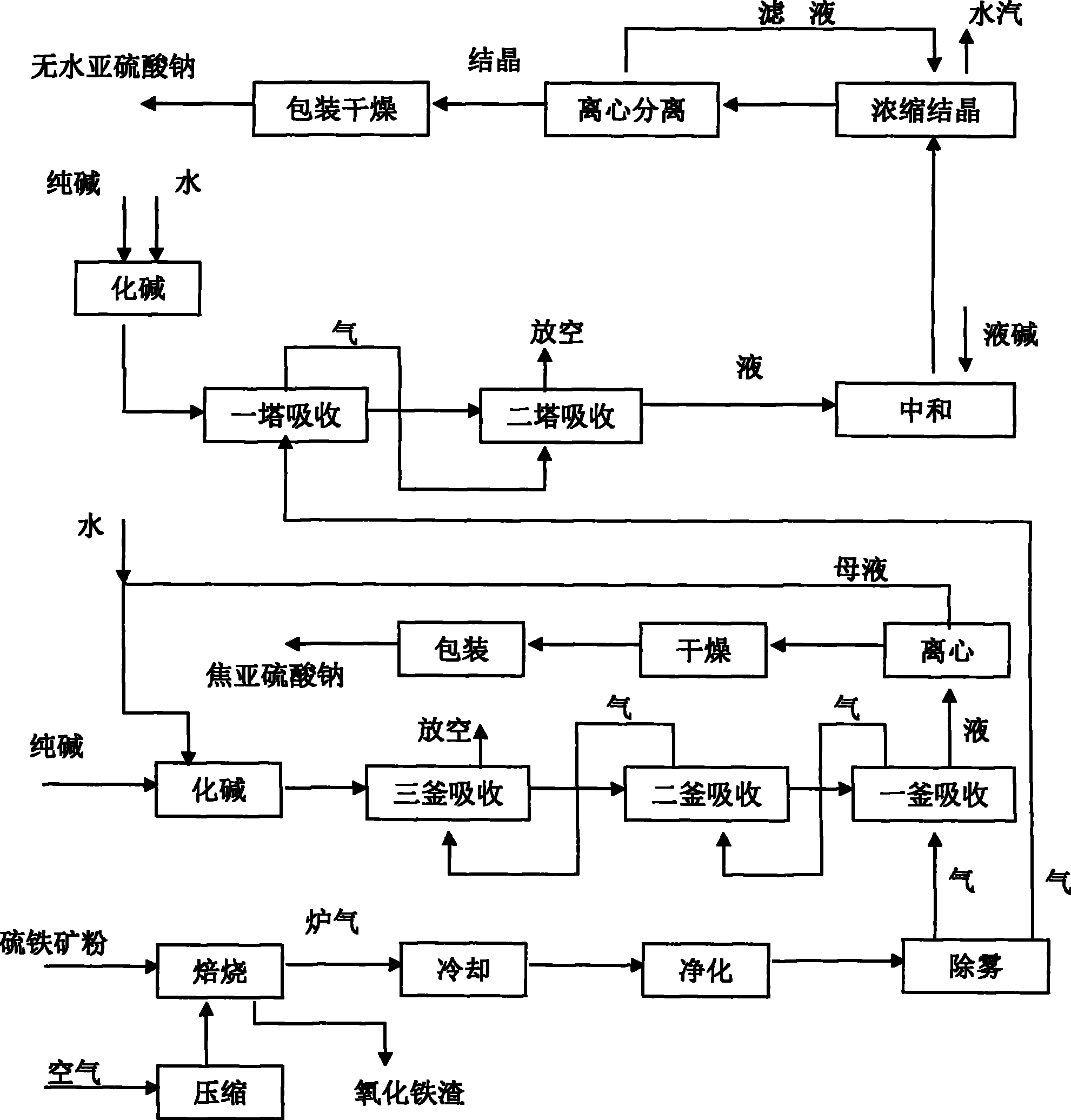

[0019] see figure 1 As shown, the present invention provides a preparation device and preparation method of sodium metabisulfite and anhydrous sodium sulfite. The production device includes a roasting system, a sodium pyrosulfite production system and an anhydrous sodium sulfite production system respectively connected to the roasting system.

[0020] The roasting system includes a fluidized fluidized furnace connected in sequence through pipelines, a cooling device connected to the fluidized fluidized furnace, a purification device connected to the cooling device, a demisting device connected to the purification device, and an air supply device connected to the fluidized fluidized furnace to deliver air into the fluidized fluidized furnace . Wherein, the demisting device is respectively connected to the sodium pyrosulfite production system and the anhydrous sodium sulfite production system through pipelines, and the fluidized furnace is used to accommodate sulfur-containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com