Multi-phase separation device and method of mixed household refuse slurry

A multi-phase separation and domestic waste technology, applied in chemical instruments and methods, flotation water/sewage treatment, water/sewage treatment, etc., can solve the problems of high concentration, unreachable, long fermentation time, etc., and achieve separation efficiency High, easy to operate, simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

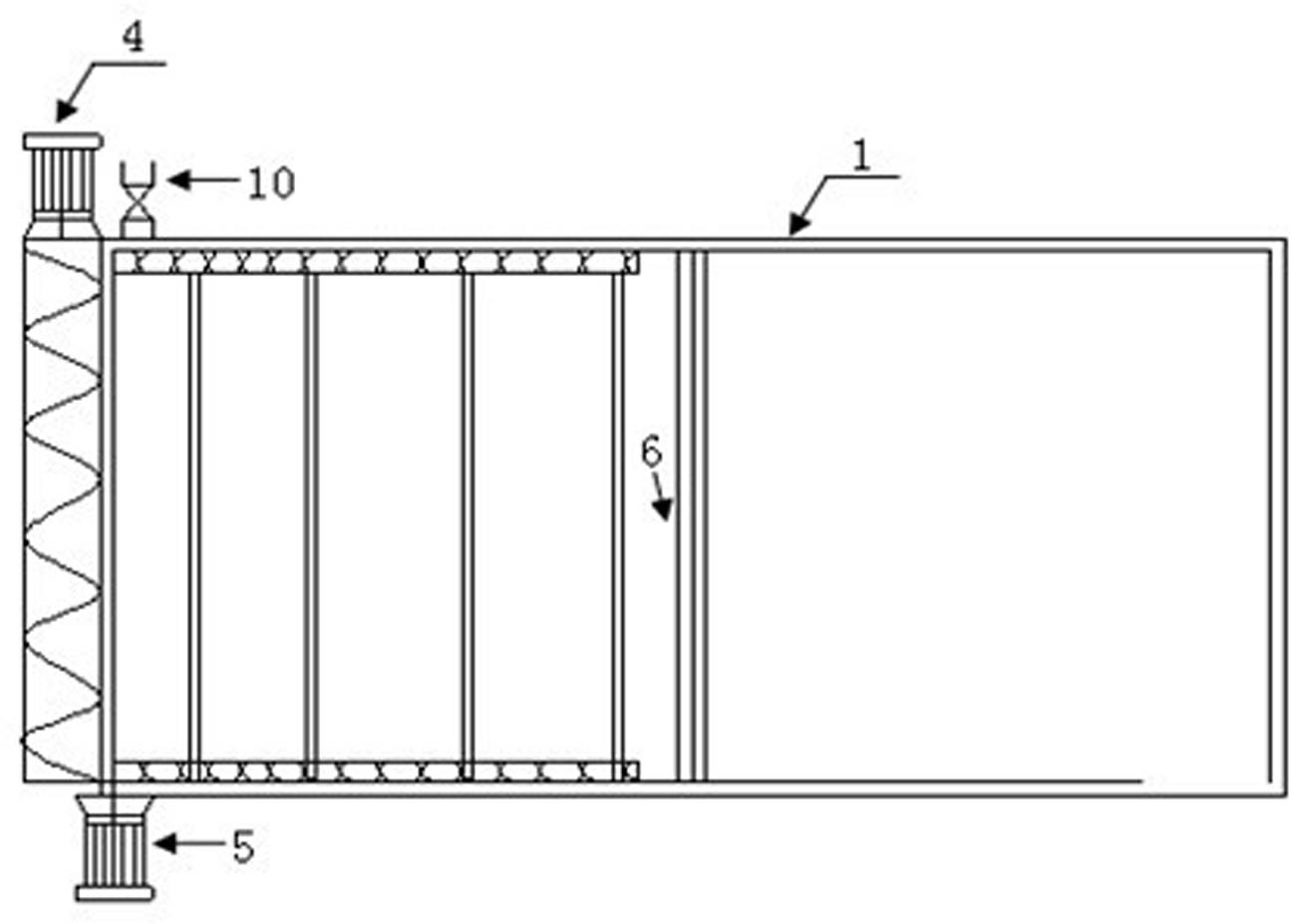

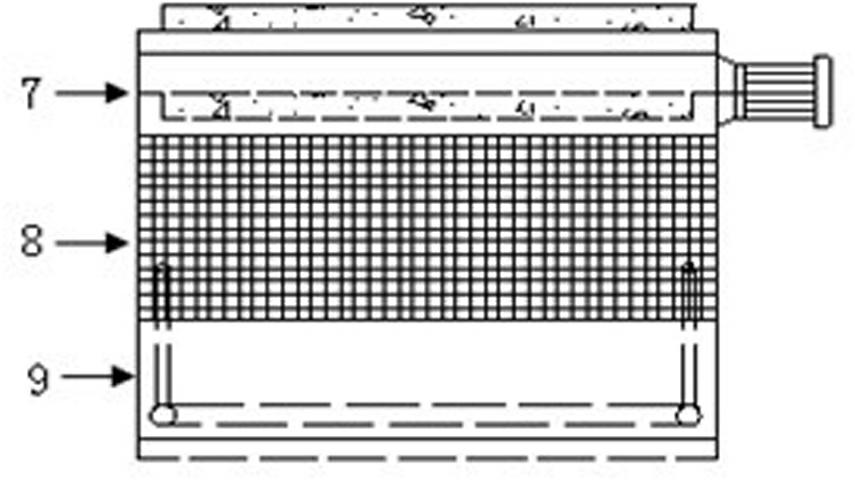

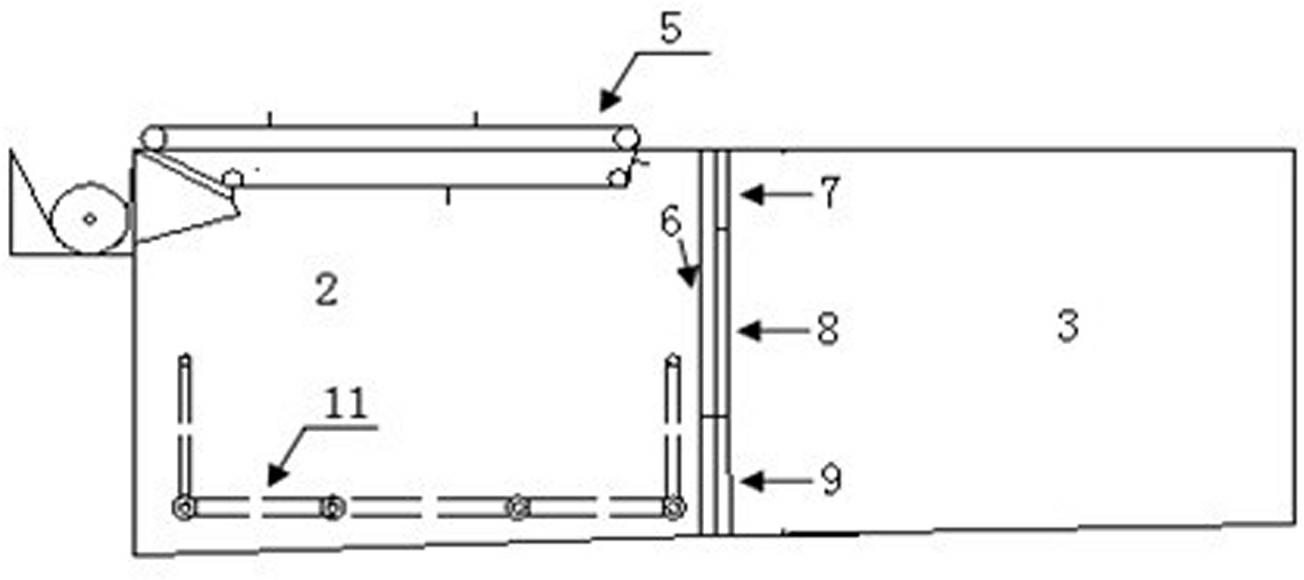

[0027] refer to Figure 1-3 A multi-phase separation device for mixing domestic waste slurry in the present invention is a large pool body 1, including an active separation device arranged in the middle of the pool body 1 and dividing the pool body 1 into A pool 1-1 and B pool 1-2 Separator 2, upper fixed plate 3, grid 4, and lower fixed plate 5 arranged side by side with movable separator 2 and vertically arranged, a slag removal device is installed on the upper part of A pool 1-1, and a gas dispersion device is installed on the bottom of the pool. Device 9 and emptying valve 8, the bottom of the pool is inclined, and pool B 1-2 is a temporary storage pool for organic slurry.

[0028] The slag removal device is composed of a screw propeller 6 and a chain slag scraper 7 .

[0029] The grid hole size on the grid 4 is 1-2cm.

[0030] A multiphase separation method for mixed domestic waste slurry, comprising the steps of:

[0031] (1) Set up a domestic waste slurry multiphase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com