Numeric control processing method for single-curvature-degree coating chemically-milling sample plate

A processing method and template technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as difficult quality assurance, low accuracy, and poor coordination and consistency of samples, so as to improve the degree of automation, ensure processing deviation, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

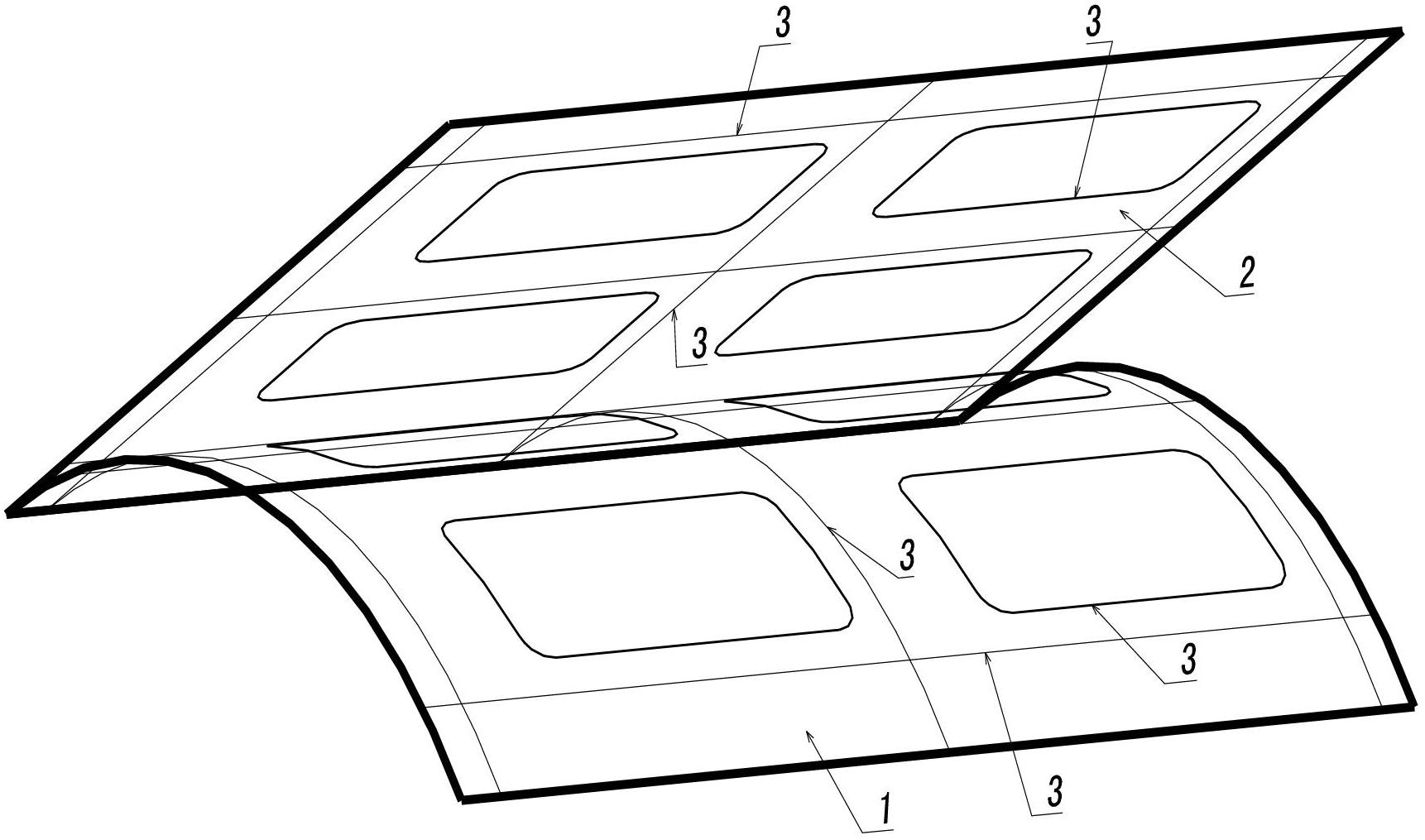

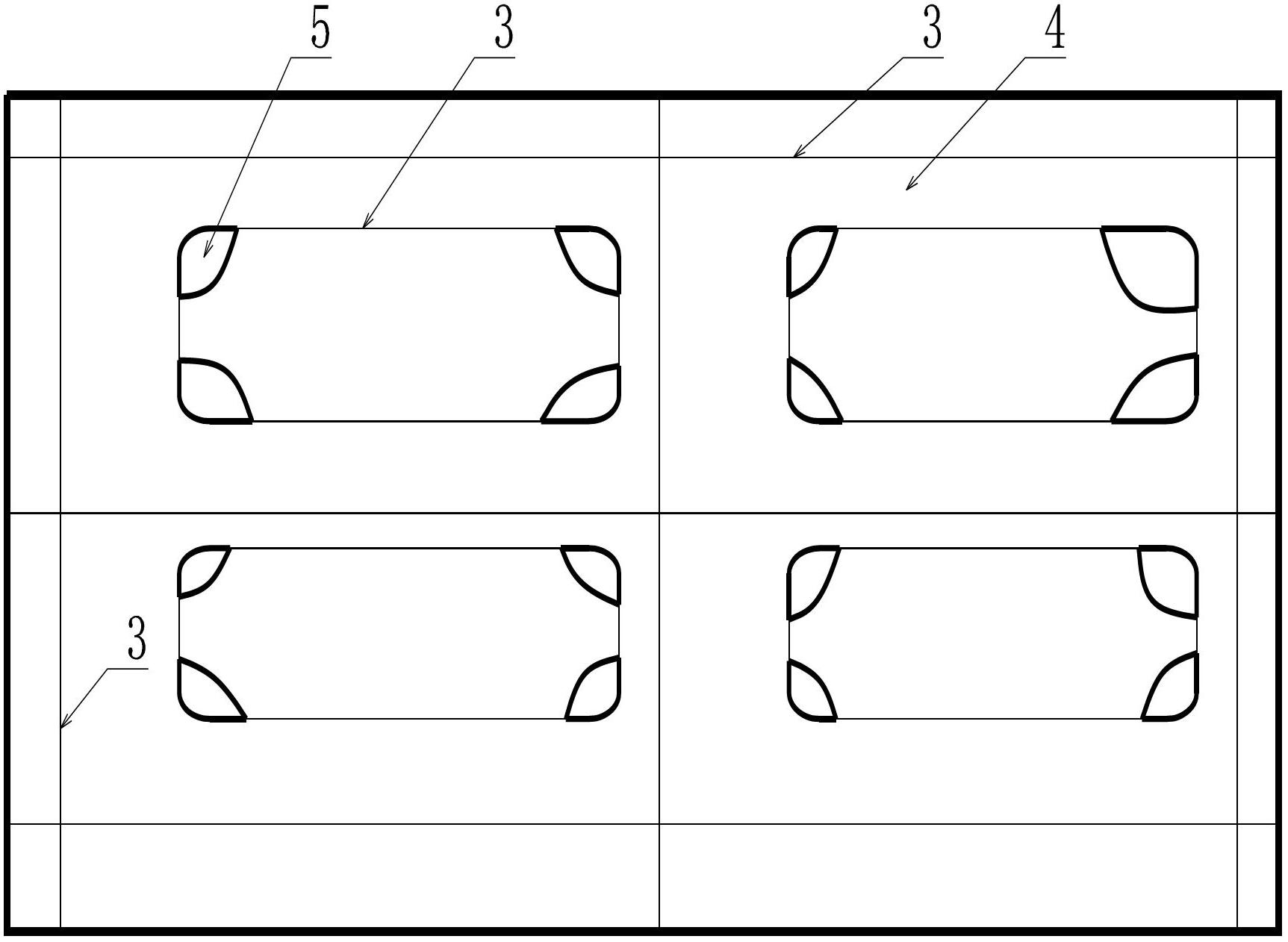

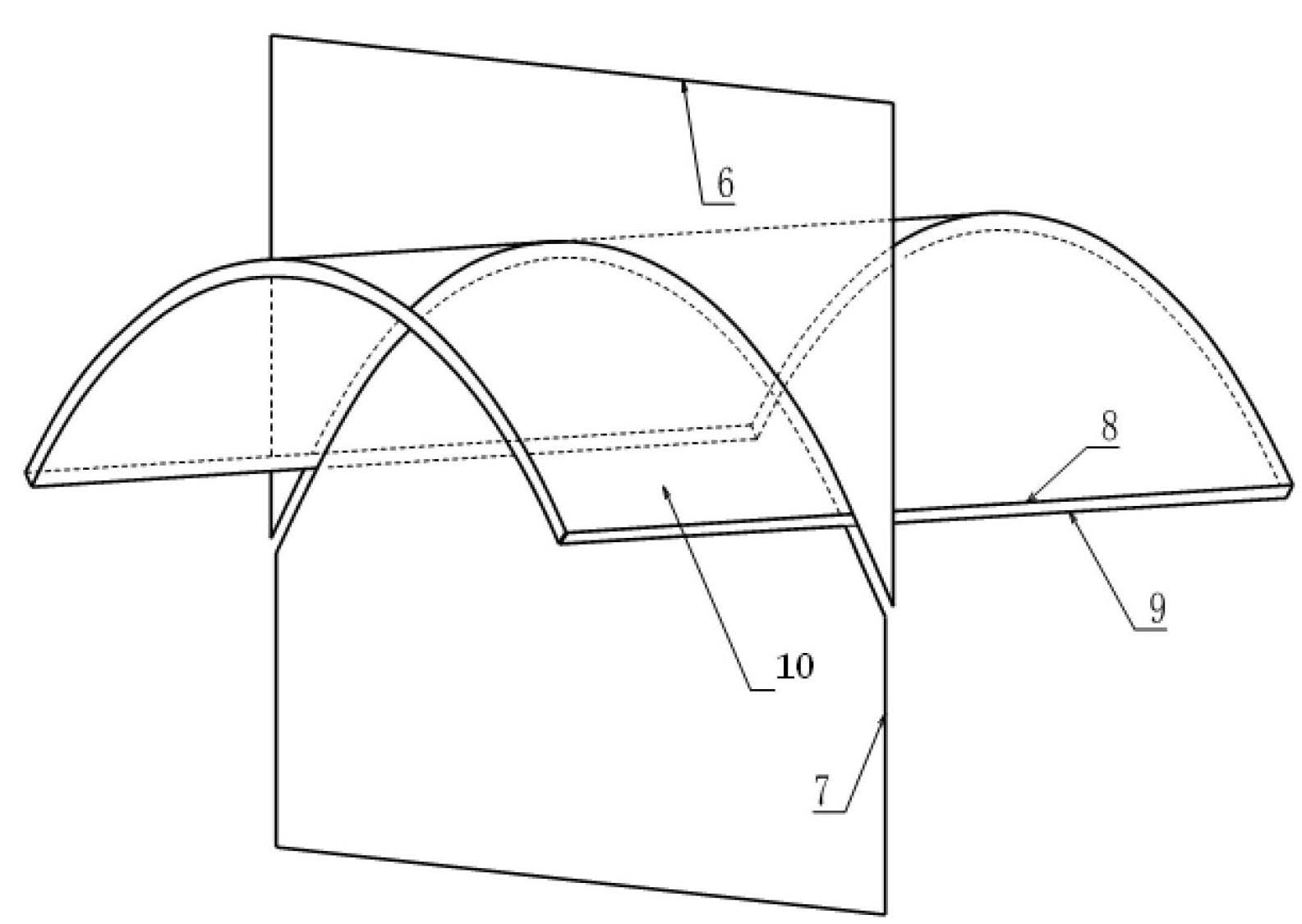

[0012] The present invention is a numerical control processing method for a single-curvature skin chemical milling template, which mainly includes the following steps: first, the theoretical data 1 of a single-curvature skin part that needs chemical milling is developed by a computer system to form a two-dimensional plane figure 2 ; Secondly, according to the two-dimensional plane figure 2 Compile the NC machining program; process the plane sample 4 on the sample plate to be processed through the planar NC machining technology again; and finally form the single-curvature chemical milling sample 10 according to the back-cut outer sample 6 .

[0013] figure 1 It is shown that the theoretical data 1 of the part is expanded by computer software to form a two-dimensional plane figure 2 , there is a chemical milling mark line 3 on the expanded plan. figure 1 The chemical milling marking line 3 shown in generally includes the truss axis, the chemical milling end line, the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com