Addressing system for controller of hydraulic support for mine, and its addressing method

A hydraulic support and controller technology, applied in mine roof support, sequence/logic controller program control, electrical program control and other directions, can solve problems such as clumsiness and error-prone, reduce error rate and improve addressing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

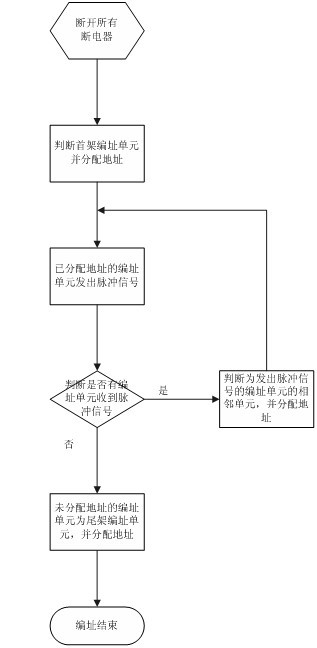

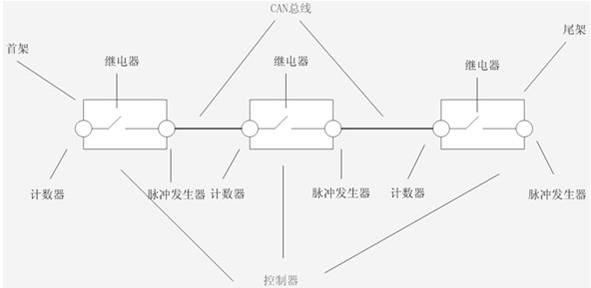

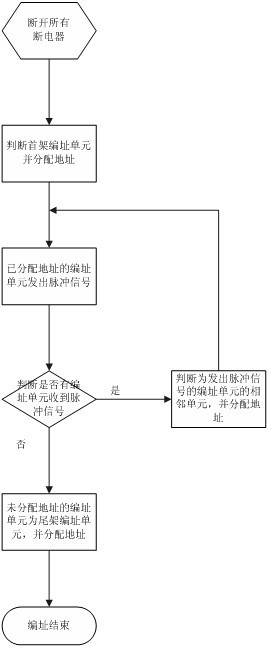

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

[0024] The addressing system for the mine hydraulic support controller is characterized in that: the system includes an addressing unit installed on each mine hydraulic support controller, a CAN bus and a general controller, and the addressing unit passes CAN The bus is connected sequentially, and the addressing units are respectively connected to the general controller. The addressing unit includes a pulse generator, a pulse counter and a relay. The pulse generator is connected to the pulse counter through the relay. The bus is connected to the pulse counter on the believed addressing unit.

[0025] In order to realize that the master controller can accurately control each mine hydraulic support, the master controller needs each mine hydraulic support controller to assign address information, and the master controller identifies the mine hydraulic support controller th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com