Optical splitting system of flattening convex surface grating

A convex grating and spectroscopic system technology, applied in the field of spectroscopic instruments, can solve the problems of complex structure of the spectroscopic system, high requirements for production, installation and debugging, and achieve the effects of wide application range, low production cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

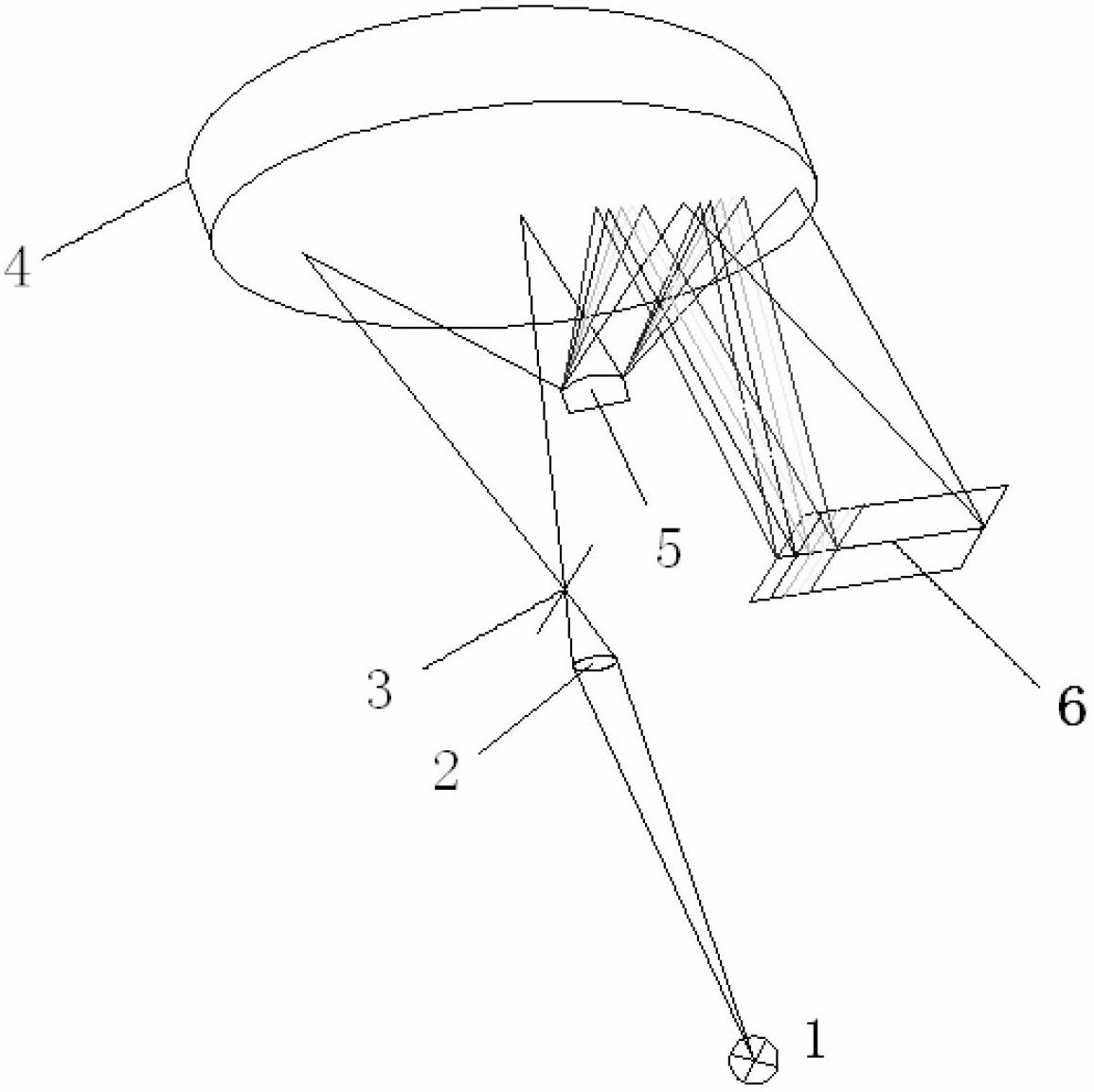

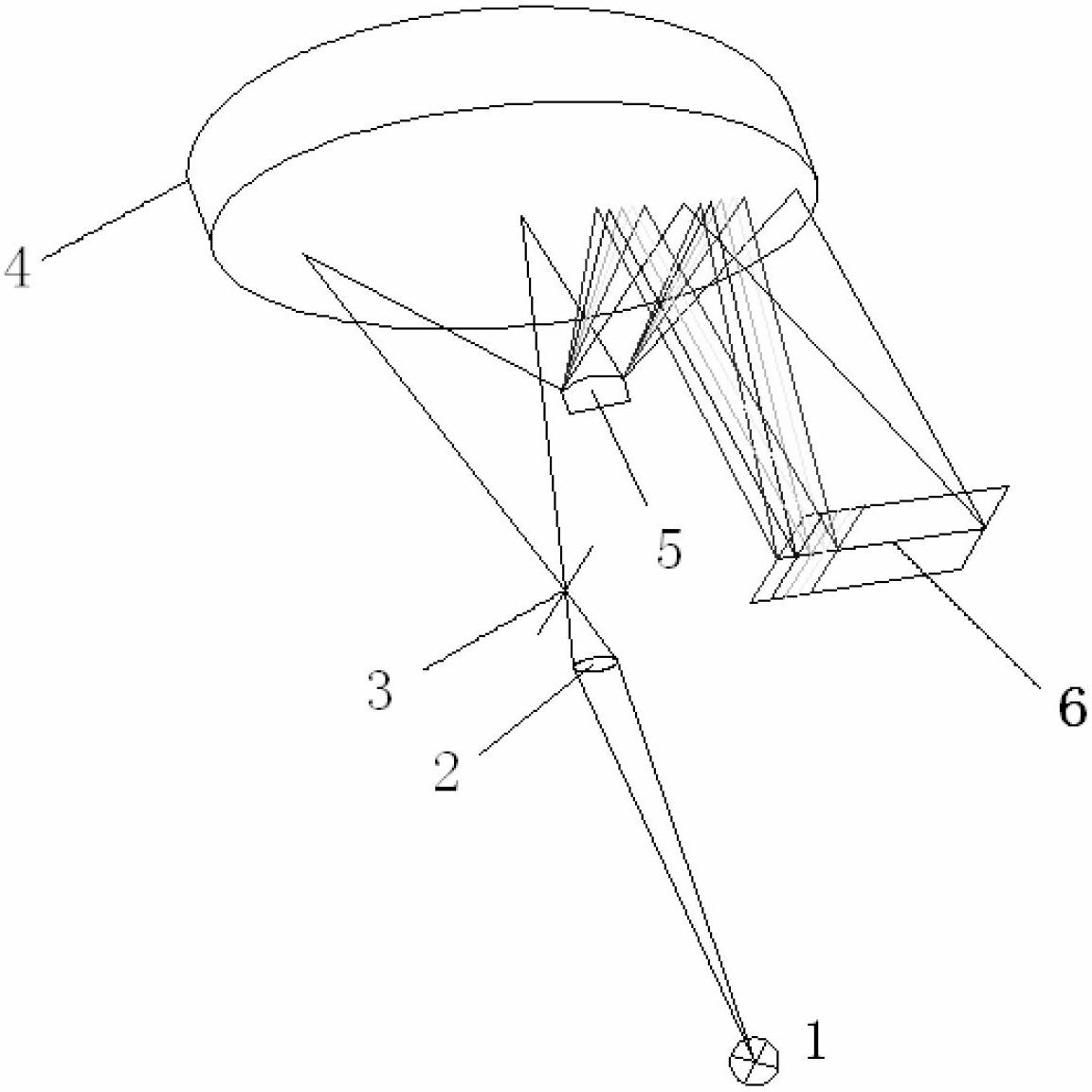

[0013] The structure of the flat image field convex grating spectroscopic system is as follows: figure 1 Shown: includes light source 1, condenser lens 2, entrance slit 3, large concave mirror 4, convex grating 5 and area array detector 6.

[0014] The steps to build a convex grating spectroscopic system are as follows:

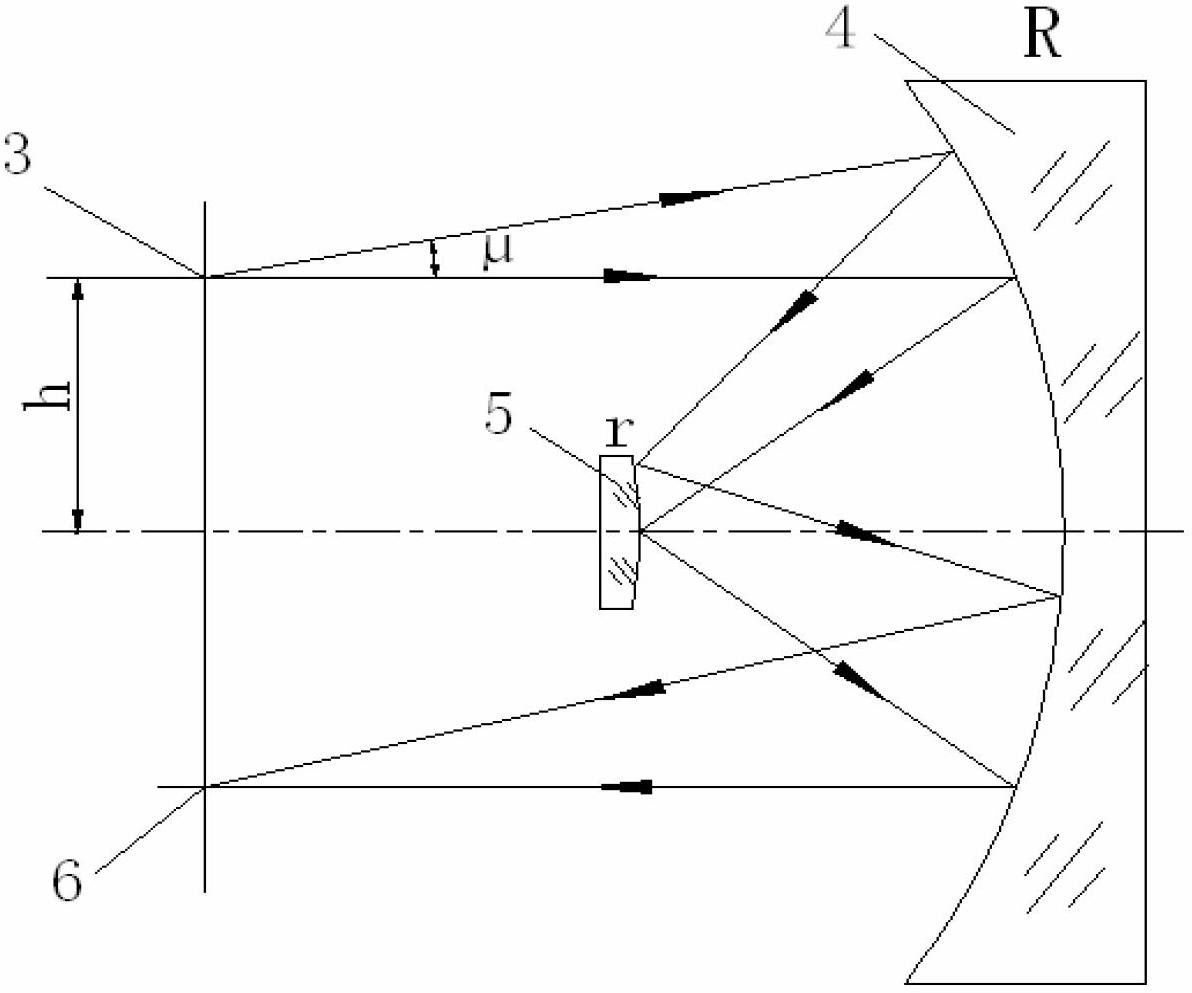

[0015] 1. Select a convex grating 5 and a large concave reflector 4, so that the radius r of the convex grating is greater than the radius R / 2 of the concave reflector, namely:

[0016] 2. Place the spherical center of the convex grating 5 and the large concave reflector 4 on the same point, and the optical axes coincide to establish a concentric and coaxial light splitting system.

[0017] 3. Place the incident slit 3 in the plane that passes through the common spherical center of the convex grating 4 and the large concave refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com