Automatic sampling device and control method thereof

A technology of automatic sample preparation and control center, which is applied in the field of automatic mechanical processing of coal samples from sample preparation to packaging, and unmanned automatic sample preparation of coal samples, which can solve the problems of poor confidentiality, low sample preparation efficiency, and complicated procedures. To achieve the effect of pure sample data and reduce human interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

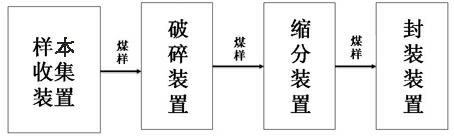

[0023] The unmanned automatic sample preparation device of the present invention is as figure 1 As shown, it includes a sample collection device, a crushing device, a shrinking device, a packaging device, a control circuit and a belt conveyor, and the coal sample is sequentially transported between each device through the conveyor belt conveyor.

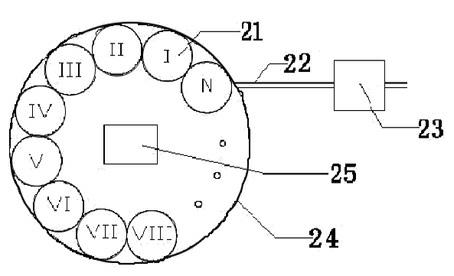

[0024] Such as figure 2 The sample collection device shown includes a sample bucket 21, a pull rod 22 with a motor 23, a sample bucket fixed tray 24, a control circuit 25, and there are N sample buckets 21 on the sample bucket fixed tray 24, N≥1, and the lower part of each sample bucket is Sealed by a pull rod 22, the pull rod is electrically connected to the control circuit 25, and the collected samples are collected in the sample collection device, which contains N sample barrels 21, and the sample barrels of the specified number can be collected by the control circuit 25 of the sample collection device. 21 turns to the fixed pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com