Piezoelectric coefficient detection method

A piezoelectric coefficient and detection method technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., to achieve the effects of improving accuracy, reducing deviation, and reducing needle tip deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

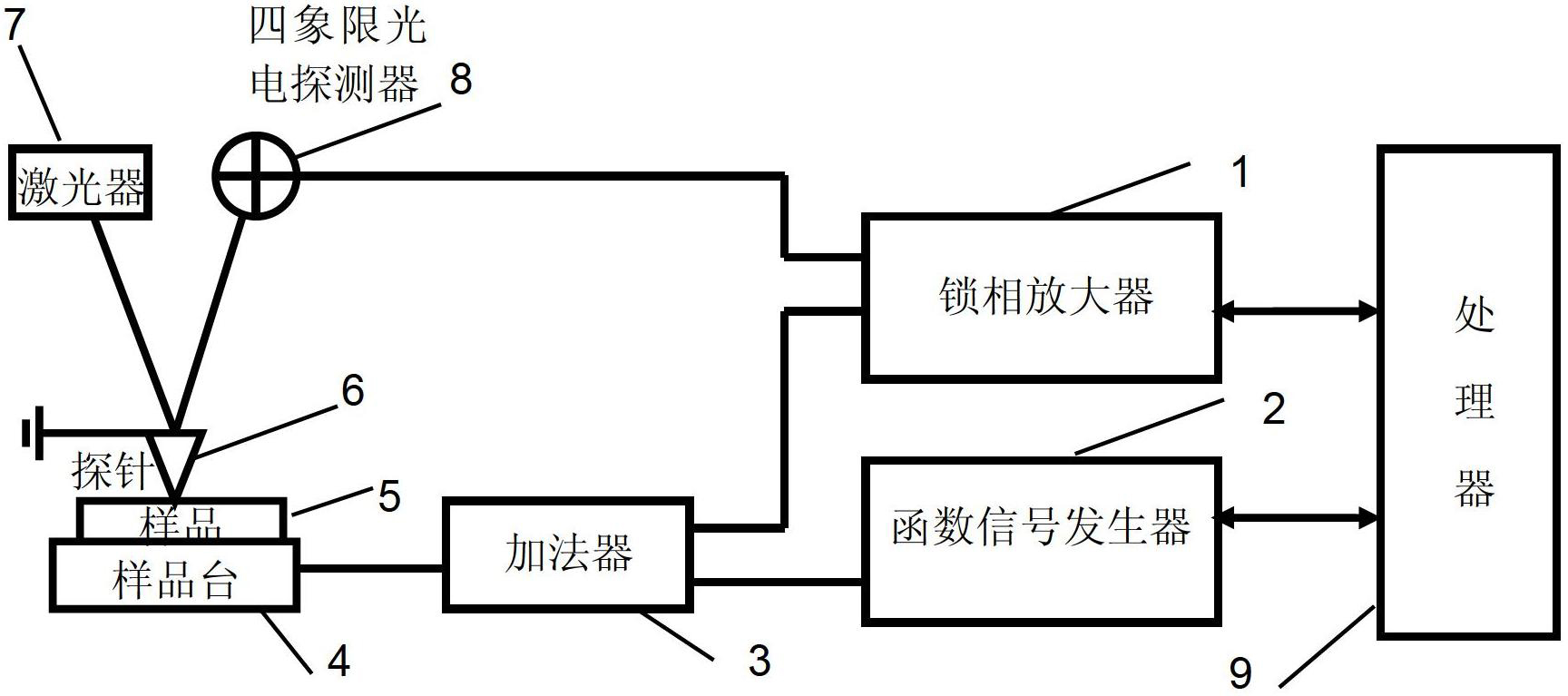

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The piezoelectric coefficient detection method of the present invention specifically comprises the following steps:

[0027] S1. Place the piezoelectric material with the bottom electrode to be tested on the sample stage of the atomic force microscope, and touch the area of the sample to be tested with a conductive probe.

[0028] S2. Every once in a while, load a DC pulse Vdc between the tip of the atomic microscope and the piezoelectric material to be tested;

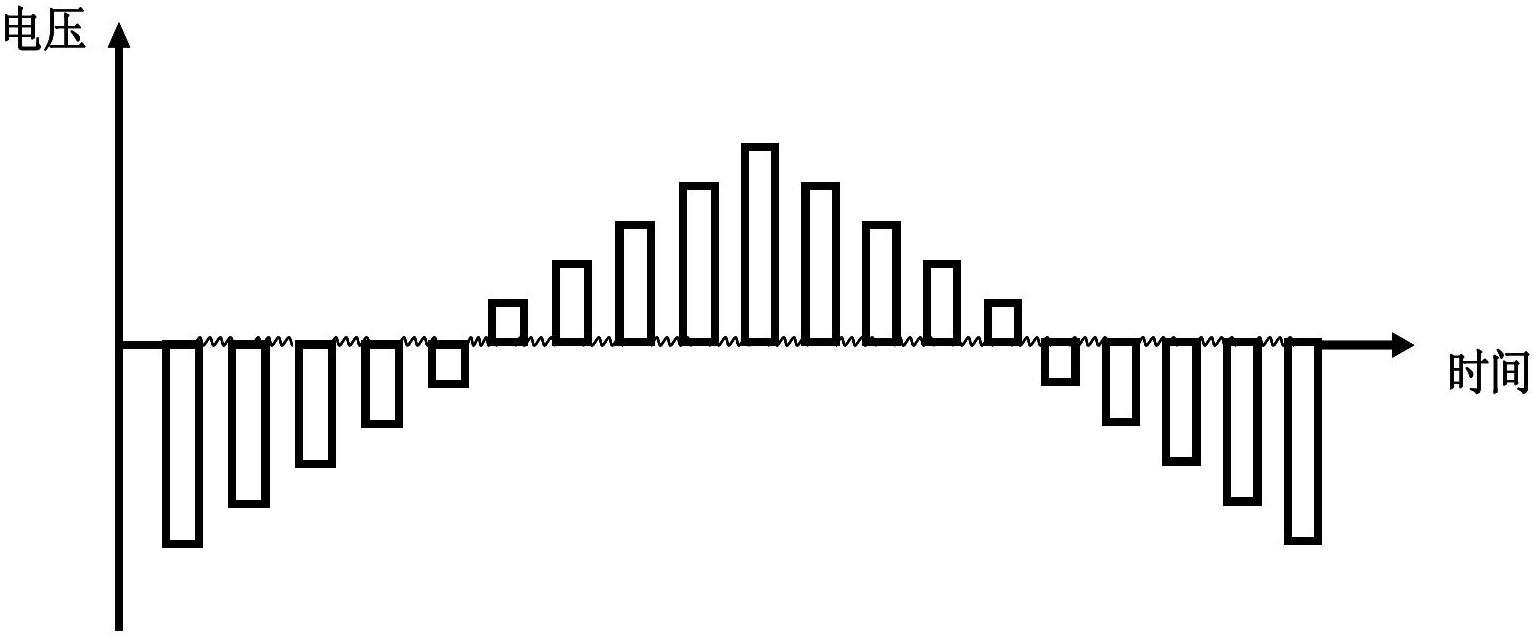

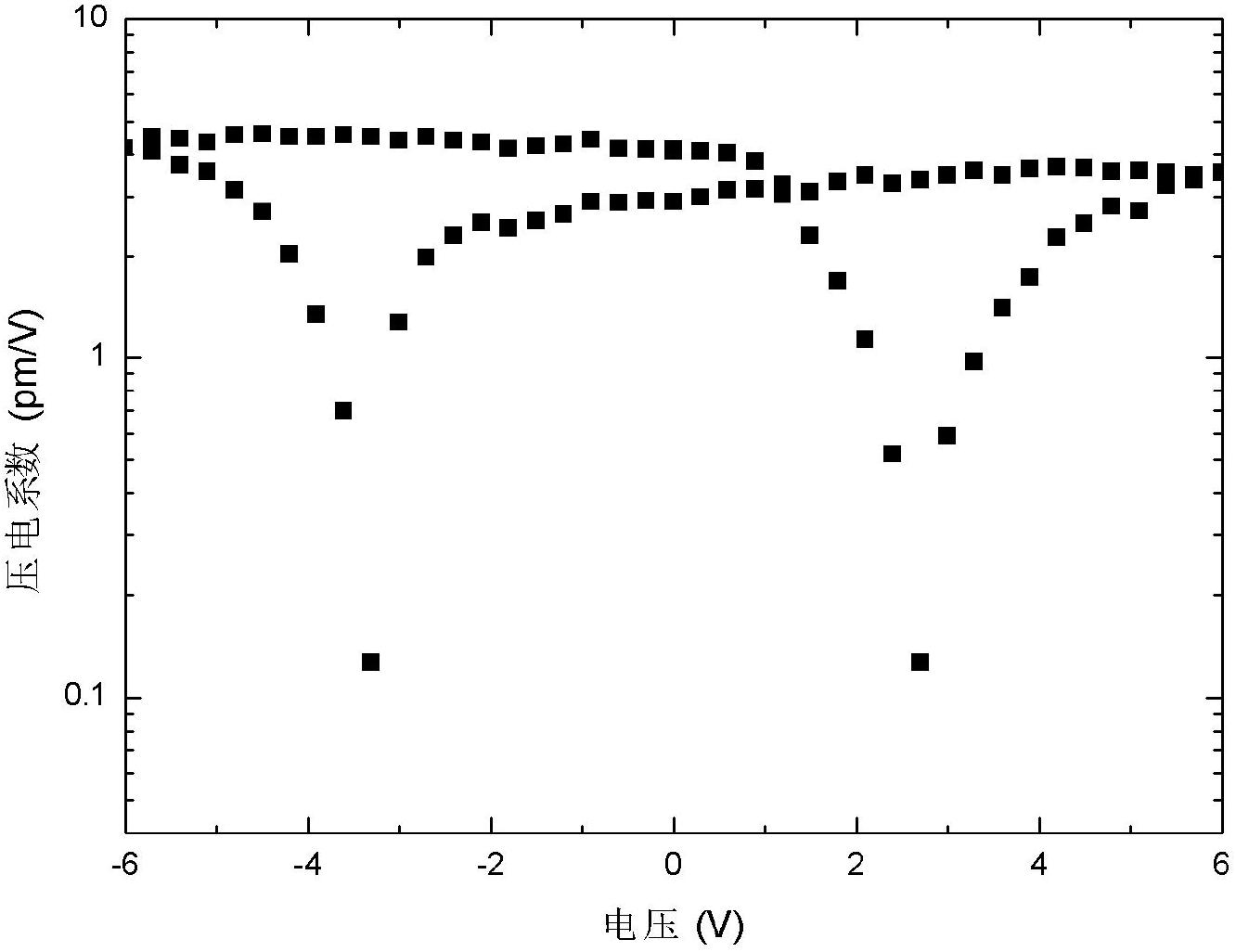

[0029] If the piezoelectric material to be tested is a nonlinear piezoelectric material, the magnitude of the loaded DC pulse satisfies:

[0030] The size of the DC pulses in adjacent intervals is firstly increased and then decreased, that is, it increases sequentially from the preset minimum value until it increases to the preset maximum value, and then decreases sequentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com