Corrugated packing grid and structured packing assembled from several packing grids

A corrugated, structured technology used in lighting and heating equipment, chemical instruments and methods, chemical/physical processes, etc., which can solve problems such as high mechanical strength limitations and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

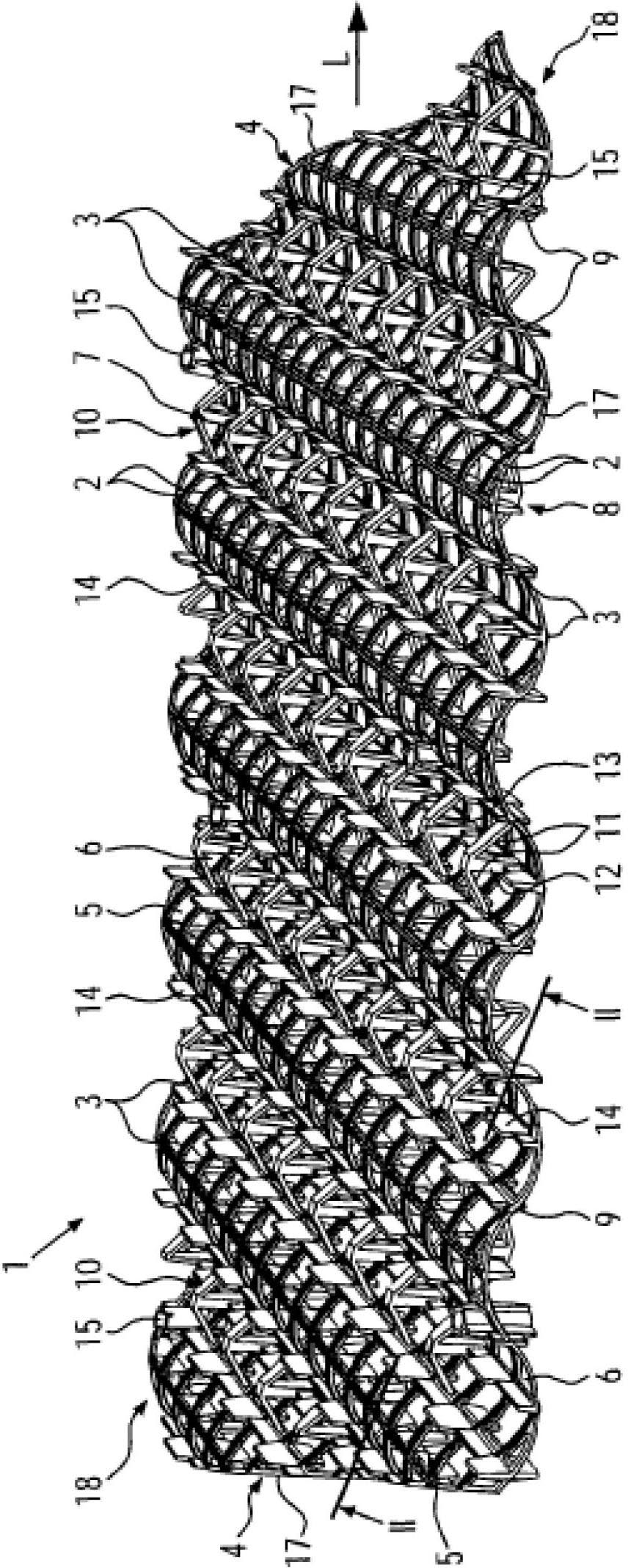

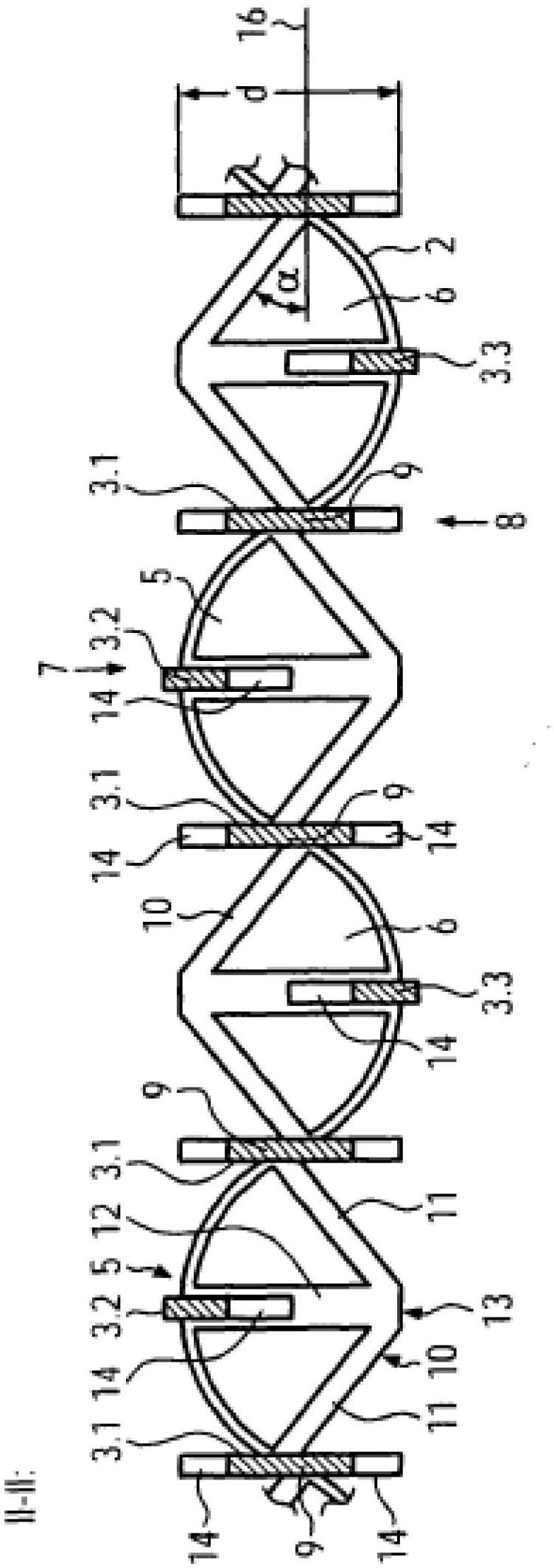

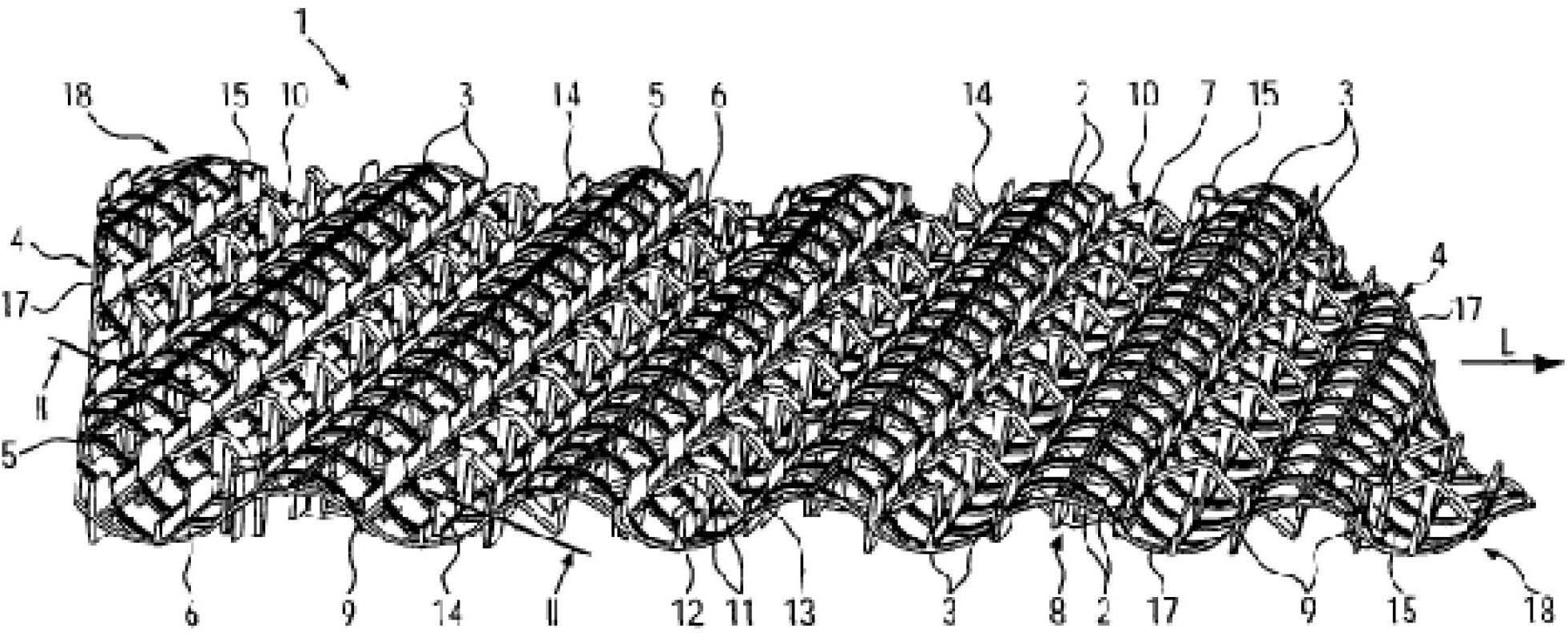

[0032] figure 1 Perspective view showing packing grid 1. The packing structure grid 1 has the basic shape of a rectangular plate, thus comprising a front side 7, a rear side 8, two narrow sides 4, two longitudinal sides 18 and a thickness d. The packing structure grid 1 is corrugated and provided with crests 5 and troughs 6 extending transversely to the direction L of its longitudinal extension. Through the crests 5 and troughs 6 , grooves are formed in the packing structure grid 1 . Plastic is preferably used as material for filling the structural grid 1 .

[0033] In the following, the front view or front side 7 of the packing structure grid 1 is described. The corrugated packing structure grid 1 has a periodically repeating structure. This means that the continuous waves filling the structural grid 1 are essentially identically represented. Furthermore, each half-wave of a wave filling the structural lattice is point-symmetric with respect to the reversal point of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com