Method for increasing the strength of components made of steel under cyclic load

A cyclic load, steel component technology, which is applied to the pressure bearing components of fuel injection systems and the pressure bearing capacity of high mechanical load components, can solve problems such as the adverse effects of cyclic pressure bearing capacity, and achieve improved tolerance and residual stress. The effect of stabilizing and improving the cyclic pressure capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

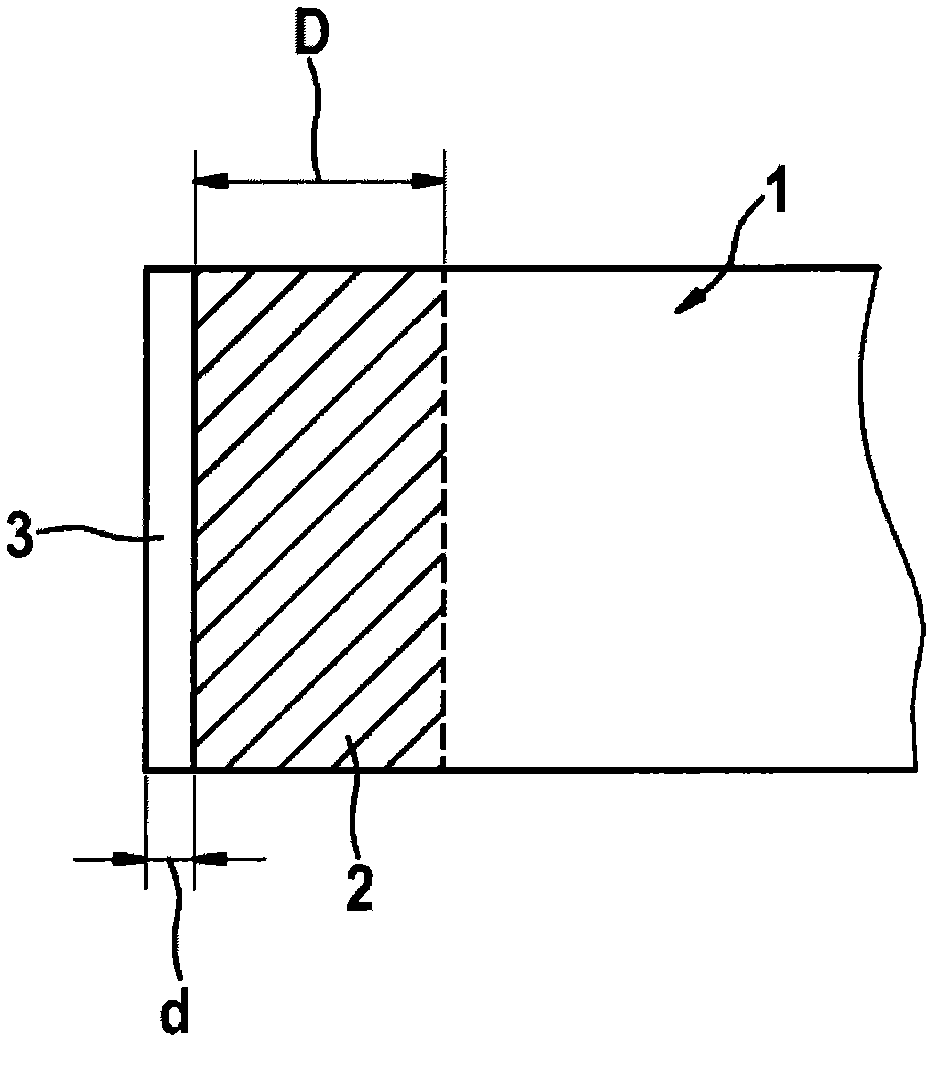

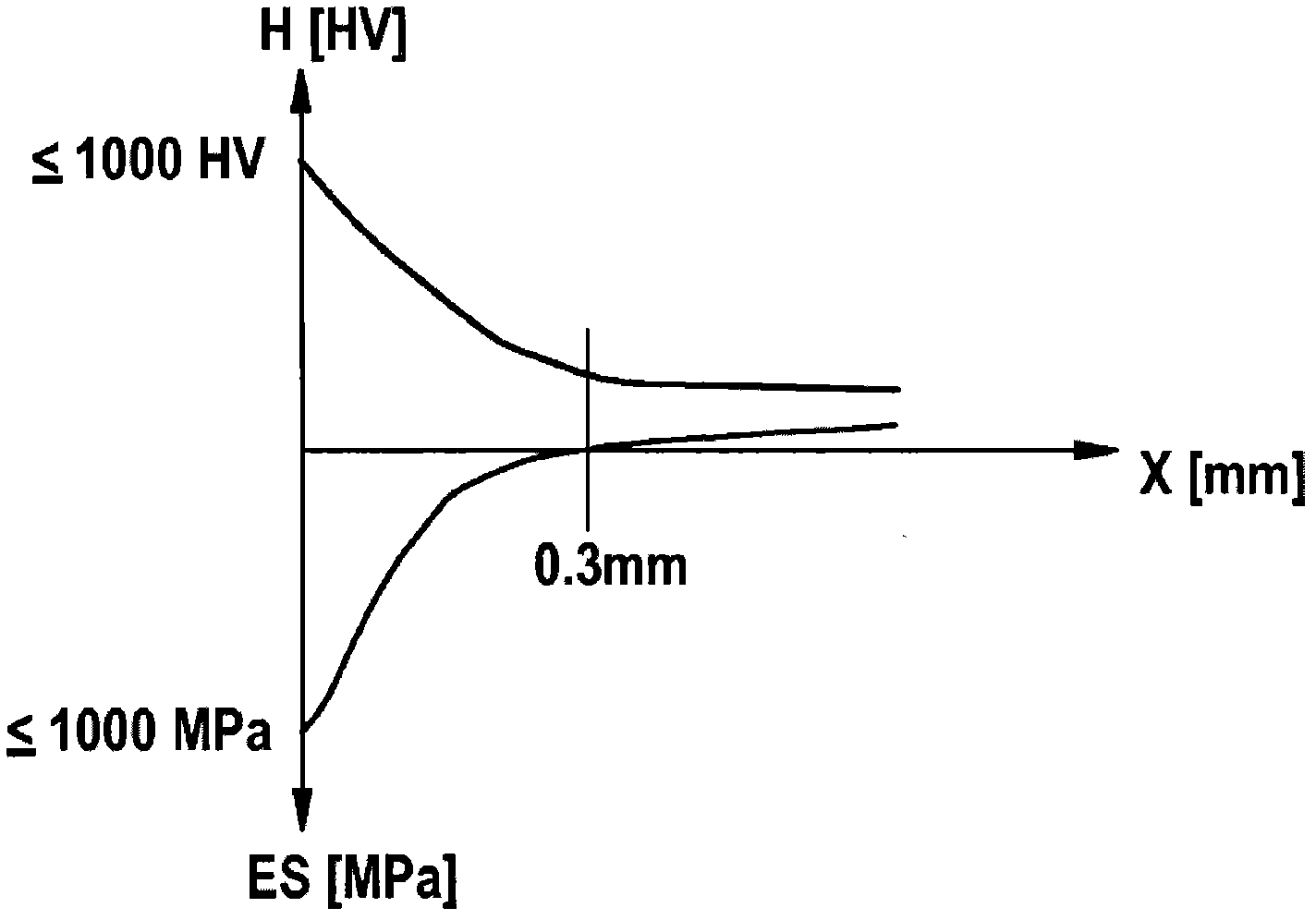

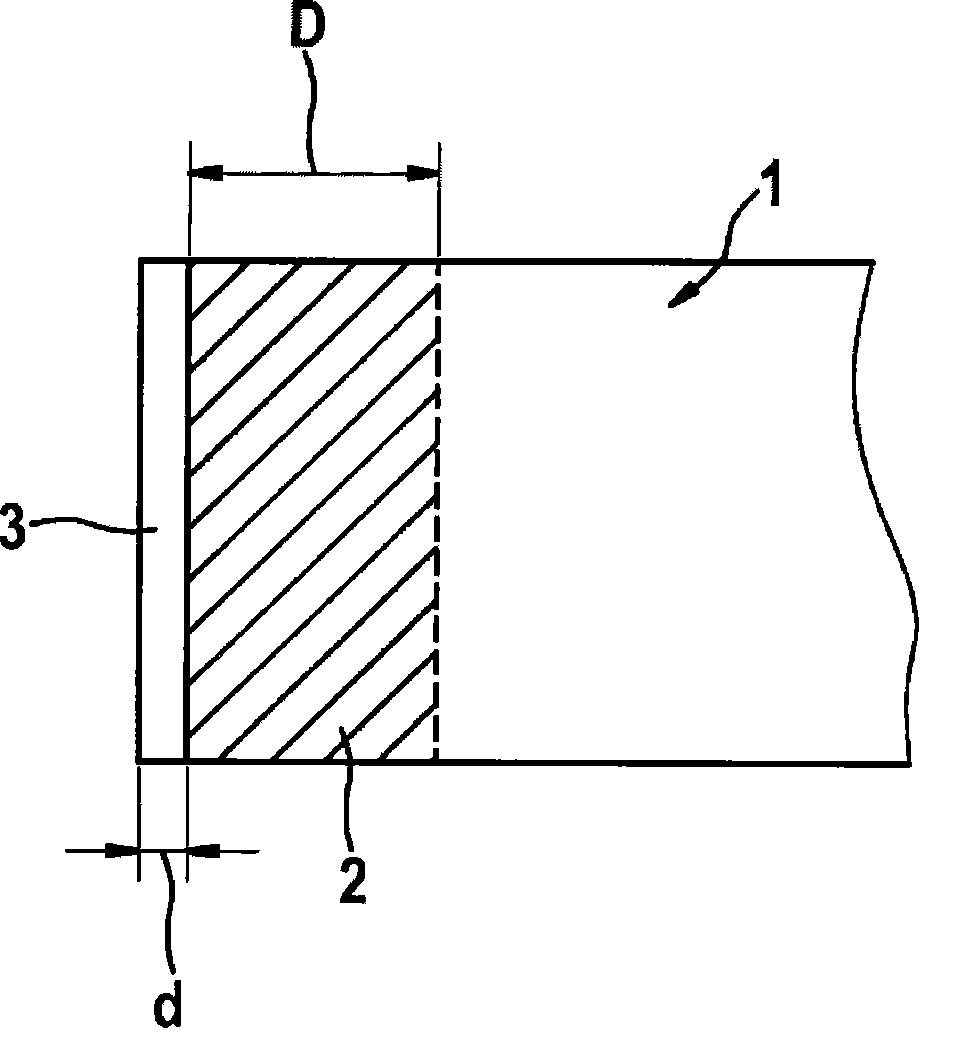

[0041] exist figure 1 The component 1 shown schematically in , is made of steel, in particular pressure-bearing and / or mechanically highly loaded components of a fuel injection system. In order to increase the pressure-bearing capacity of the component 1 under cyclic loading conditions, a residual compressive stress distribution is selectively introduced into the component surface, which counteracts the load distribution acting on the component surface under cyclic loading conditions. By gas nitriding the component at a nitriding temperature between approximately 420° C. and approximately 620° C. for a duration of nitriding depending on the desired target strength, the residual pressure is selectively reduced by means of gas nitriding of the component 1 Stresses are introduced into the surface of the component. The nitriding duration can be up to 96 hours, preferably between 2 and 12 hours.

[0042] Gas nitriding not only introduces a nitride diffusion layer 2 into the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com