Autorotation type soilless planting greenhouse capable of acquiring natural energy in multiple directions

A natural energy and soilless planting technology, applied in soilless cultivation, botanical equipment and methods, greenhouse cultivation, etc., can solve the problem of low material selection and structural strength, inability to withstand natural disasters such as strong winds, hail, floods, and lack of natural resources. Energy and other issues, to achieve the effect of convenient use and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

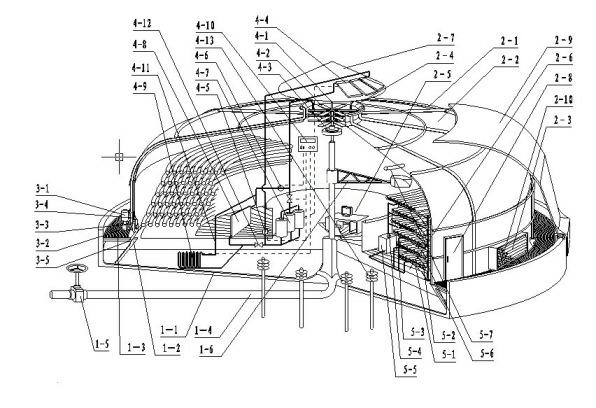

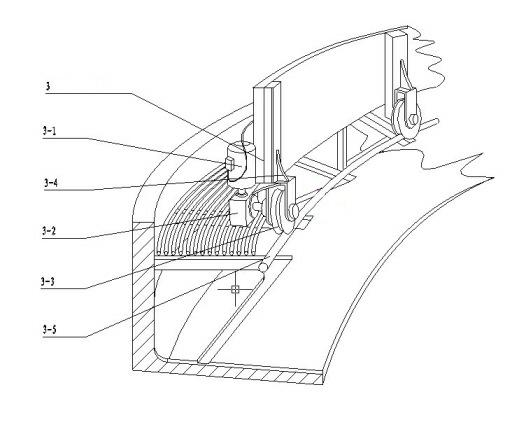

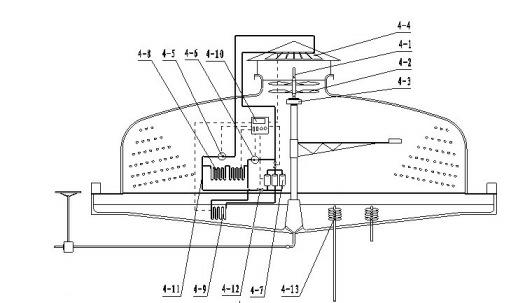

[0021] Example: a structure such as figure 1 figure 2 and image 3As shown, it is composed of base and pool part 1, transparent inflatable cover part 2, rotation drive mechanism 3, energy acquisition device 4 and three-dimensional planting frame part 5, among which the base and pool part 1 is built on the ground plane The following disc-shaped masonry cement structure with an upward opening is provided with several track supports 1-2 around the structure, and the circular track 3-5 is erected on the track support 1-2, and the transparent inflatable outer cover part 2 passes through the bottom around The rollers and the self-rotating drive mechanism 3 are located on the circular track 3-5, and the energy acquisition device 4 is a thermal airflow turbofan power generation device installed on the top of the transparent inflatable outer cover part 2, a solar heat collection device, and geothermal heat pipes installed in the pool and underground The three-dimensional planting fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com