Square-module-type fiber fixed-disc filtering machine

A fiber fixing and modular technology, which is applied in the direction of fixed filter element filter, filtration separation, separation method, etc., can solve the problems of rotation driving motive force, high production cost, and complicated assembly, so as to avoid friction loss, reduce cost, The effect of avoiding mechanical friction and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

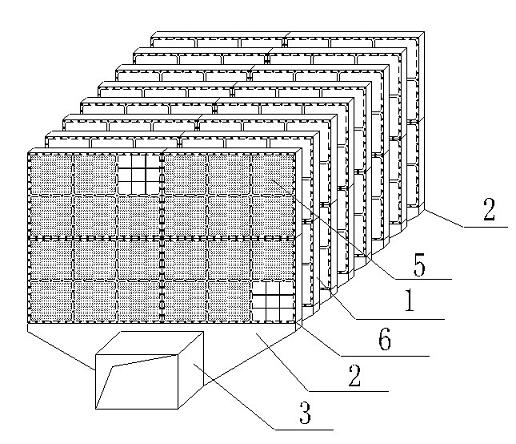

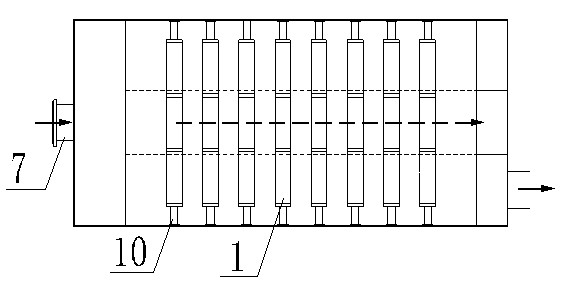

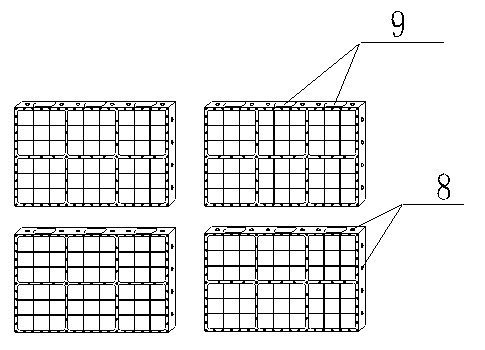

[0025] Such as figure 1 As shown, a square modular fiber fixed disc filter, it includes a plurality of modular filter discs 1 installed in the filter tank, water collecting bucket 2 and total sump 3, each modular combined filter disc 1 has several The square unit module 6 is composed of each combined filter plate 1 arranged in parallel, and a water inlet pipe 7 runs through it, and a water collecting bucket 2 is arranged at the bottom of the filter tank below each combined filter plate 1, and a water collecting bucket 2 is arranged in each water collecting bucket 2. The slot for fixing the combined filter plate 1, and the water outlets of each water collecting bucket 2 are connected with the general water collecting tank 3.

[0026] The total sump 3 of the present invention communicates with the water outlet bin at the end of the filter, and the two si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com